Gastrodia elata film coated micro-pill preparation and preparation method thereof

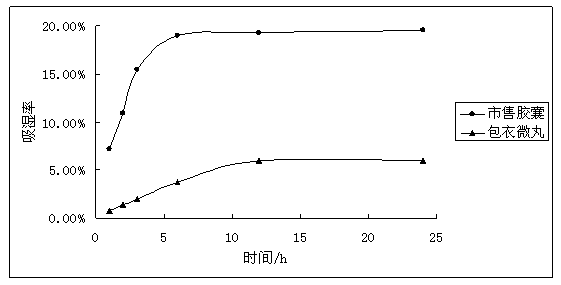

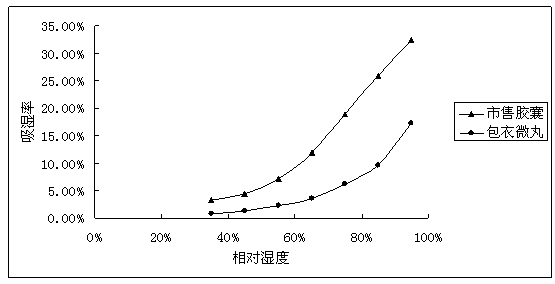

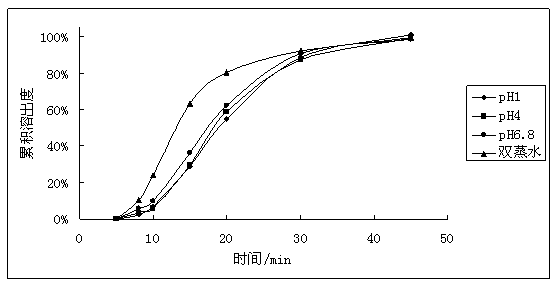

A technology of film coating and pellets, which is applied in the field of pharmaceuticals, can solve the problems of unfavorable long-term storage and use, strong hygroscopicity, poor stability, etc., and achieve the effects of overcoming instability, less irritation, and improving moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present invention: the preparation method of Gastrodia elata film-coated pellet preparation

[0036] (1) Preparation of Gastrodia elata pellets: Dry Gastrodia elata powder and filler separately, and pass through a 100-mesh sieve; take 20g Gastrodia elata powder, 27.5g microcrystalline cellulose and 2.5g lactose and mix evenly, add the concentration of 5% by mass % PEG6000 aqueous solution was used as binder to prepare soft material; the soft material was prepared by extrusion spheronization process to obtain pellets; the extrusion frequency of extrusion spheronization process was 20 Hz, the spheronization frequency was 20 Hz, and the spheronization time was 8 min; Dry in an oven at ℃ for 3 hours, and sieve the pellets with a particle size of 18-35 mesh for subsequent use;

[0037] (2) Film-coat the pellets: use water as a solvent, dissolve Opadry® 200 solid powder, stir for 30 minutes, and prepare a film-coating solution with a concentration of 10% b...

Embodiment 2

[0038] Embodiment 2 of the present invention: the preparation method of Gastrodia elata film-coated pellet preparation

[0039] (1) Preparation of Gastrodia elata pellets: Dry Gastrodia elata powder and filler separately, and pass through a 100-mesh sieve; take 25g Gastrodia elata powder, 20g microcrystalline cellulose and 5g lactose and mix evenly, add 10% mass percentage concentration of PEG6000 aqueous solution was used as a binder to prepare soft material; the soft material was prepared by extrusion spheronization process to obtain pellets; the extrusion frequency of extrusion spheronization process was 30 Hz, the spheronization frequency was 25 Hz, and the spheronization time was 10 min; Dry in an oven for 3 hours, and sieve the pellets with a particle size of 18-35 mesh for subsequent use;

[0040] (2) Film-coat the pellets: use water as a solvent, dissolve Opadry® 200 solid powder, stir for 45 minutes, and prepare a film-coating solution with a concentration of 15% by m...

Embodiment 3

[0041] Embodiment 3 of the present invention: the preparation method of Gastrodia elata film-coated pellet preparation

[0042] (1) Preparation of Gastrodia elata pellets: Dry Gastrodia elata powder and filler separately, and pass through a 100-mesh sieve; take 30g Gastrodia elata powder, 17.5g microcrystalline cellulose and 2.5g lactose and mix evenly, add the mass percentage concentration of 15 % PEG6000 aqueous solution was used as binder to prepare soft material; the soft material was prepared by extrusion spheronization process to obtain pellets; the extrusion frequency of extrusion spheronization process was 30 Hz, the spheronization frequency was 30 Hz, and the spheronization time was 10 min; Dry in an oven at ℃ for 3 hours, and sieve the pellets with a particle size of 18-35 mesh for subsequent use;

[0043](2) Film-coat the pellets: use water as a solvent, dissolve Opadry® 200 solid powder, stir for 45 minutes, and make a film-coating solution with a mass percentage c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com