Method for preparing anti-aging steamed bread

An anti-aging and steamed bread technology is applied in the directions of food preparation, preservation of food ingredients as anti-microbials, function of food ingredients, etc., to achieve the effects of enhancing health care quality, simple operation, and inhibiting steamed bread aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

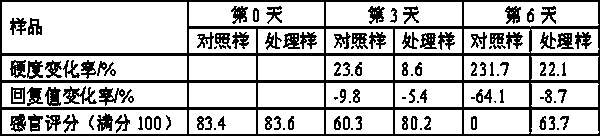

Image

Examples

Embodiment 1

[0018] The specific operation steps for making anti-aging steamed buns are as follows:

[0019] Step 1: Yeast activation: Take 1800ml of warm water at 30±2°C, add 200g of instant dry yeast, prepare a yeast solution with a mass percentage of 10%, activate it at 30±2°C for 4 minutes, and obtain an aqueous yeast solution;

[0020] Step 2: Dough preparation: Take 10kg steamed bread special flour and add it to the mixer, then add 200g yeast β-glucan, start the mixer, then slowly add 1200ml yeast aqueous solution and 6160ml warm water, and stir for 8min at a speed of 80r / min to get smooth and complete dough;

[0021] Step 3: proofing and forming: put the smooth and complete dough in a proofing box with a temperature of 32 ± 2 °C and a relative humidity of 85 ± 5% to proof for 60 minutes to obtain a proofed dough; take out the proofed dough once, cut Form dough pieces with a mass of 100 ± 5g, knead them into round shapes, and place them in a proofer with a temperature of 32 ± 2°C an...

Embodiment 2

[0028] The specific operation steps for making anti-aging steamed buns are as follows:

[0029] Step 1: Yeast activation: take 900ml of warm water at 30±2°C, add 100g of instant dry yeast, prepare a yeast solution with a mass percentage of 10%, activate it at 30±2°C for 5 minutes, and obtain an aqueous yeast solution;

[0030] Step 2: Dough preparation: Take 5kg steamed bread special flour and add it to the mixer, then add 300g oat β-glucan, start the mixer, then slowly add 550ml yeast aqueous solution and 3240ml warm water, and stir for 5min at a speed of 100r / min to get smooth and complete dough;

[0031] Step 3: proofing and forming: put the smooth and complete dough in a proofing box with a temperature of 32 ± 2 °C and a relative humidity of 85 ± 5% to proof for 75 minutes to obtain a proofed dough; take out the proofed dough once, cut Form dough pieces with a mass of 100 ± 5g, knead them into round shapes, and place them in a proofer with a temperature of 32 ± 2°C and a ...

Embodiment 3

[0038] The specific operation steps for making anti-aging steamed buns are as follows:

[0039] Step 1: Yeast activation: Take 4500ml of warm water at 30±2°C, add 500g of fresh yeast, prepare a yeast solution with a mass percentage of 10%, and activate it at 30±2°C for 3 minutes to obtain an aqueous yeast solution;

[0040] Step 2: Dough preparation: Take 5kg steamed bread special flour and add it to the mixer, then add 200g barley β-glucan, start the mixer, then slowly add 500ml yeast aqueous solution and 3160ml warm water, and stir for 7 minutes at a speed of 90r / min to get smooth and complete dough;

[0041] Step 3: proofing and forming: put the smooth and complete dough in a proofing box with a temperature of 32 ± 2 °C and a relative humidity of 85 ± 5% for proofing for 70 minutes to obtain a proofed dough; take out the proofed dough once, cut Form dough pieces with a mass of 100 ± 5g, knead them into round shapes, and place them in a proofing box with a temperature of 32 ±...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com