a threshing device

A technology of threshing teeth and threshing drums, which is applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of poor adaptability, increased cleaning loss, and cleaning of hard-to-remove crops, so as to reduce cleaning loss and increase threshing Net rate, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

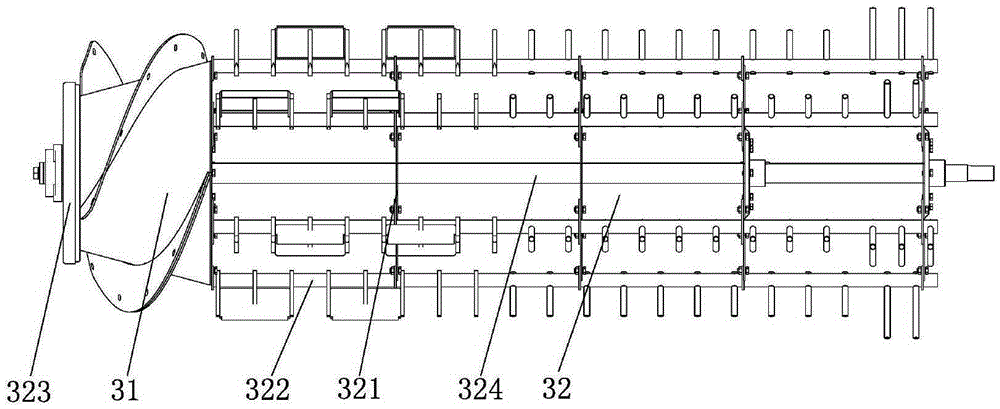

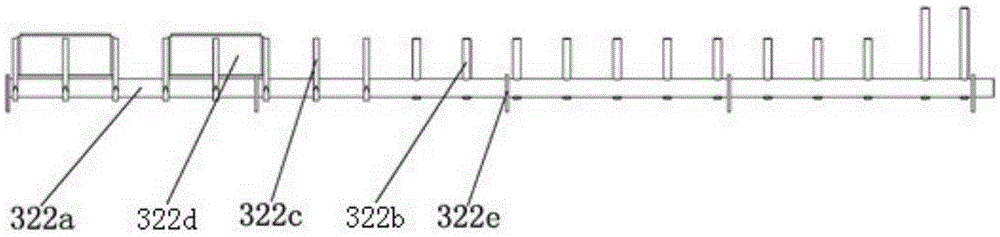

[0017] see figure 1 and figure 2 , The threshing cylinder 32 according to the present invention includes a feeding cylinder 31 , a disc 321 , a threshing gear rod welding 322 , an anti-winding disc 323 , and a drum main shaft 324 . The feeding cylinder 31 is installed at the front end of the drum main shaft 324, and the center of the feeding drum 31 is passed through by the drum main shaft 324. The threshing rack welding 322 includes a threshing rack 322a, finger teeth 322b, cast flat teeth 322c, re-extraction plate 322d, and rack connecting plate 322e.

[0018] Preferably, the structure of the threshing rack is a hollow circular tube with a diameter of 28-35 mm or a hollow square tube with a side length of 30-32 mm, and the structure of the gear rack is an ordinary steel plate with a thickness of 3-5 mm. The specific form of the threshing teeth installed on the threshing gear bar 322a is: the front section adopts cast flat teeth 322c sleeve welding, and the rear section ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com