New energy vehicle motor controller provided with capacitor and busbar integrated module

A new energy vehicle, motor controller technology, applied in the direction of motor control, control system, electrical components, etc., can solve problems such as collision friction, failure to meet new energy vehicles, desoldering and short circuit, etc., to improve reliability and vibration reliability The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings.

[0016] see Figure 4 , The new energy vehicle motor controller with capacitor bus integrated module of the present invention includes capacitor bus integrated module, controller box 11, inverter module 12, input terminal 13, output terminal 14 and capacitor output cable 15.

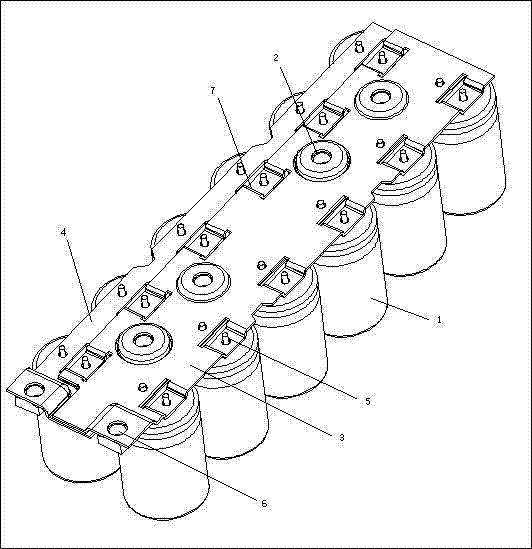

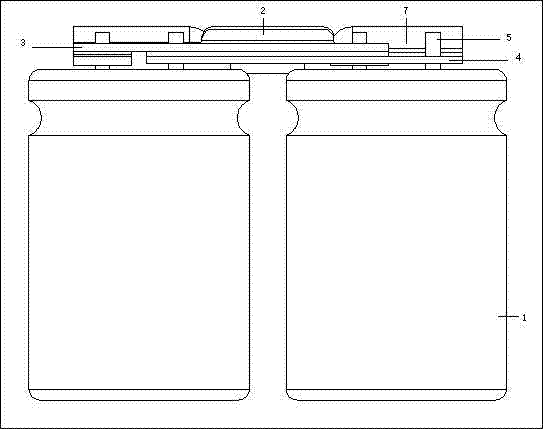

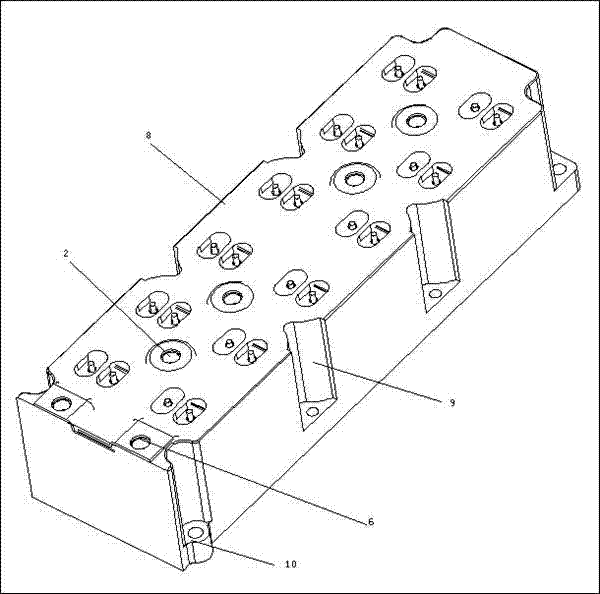

[0017] see you again figure 1 and figure 2 , the capacitor bus integrated module in the new energy vehicle motor controller with the capacitor bus integrated module of the present invention includes a capacitor 1, an upper layer copper bar 3, a lower layer copper bar 4, a capacitor column 5 and a junction block 6, an upper layer copper bar 3, a lower layer The copper bars 4 are arranged up and down as the connection of the positive and negative poles of the capacitor, and there are gaps 7 in the positions corresponding to the capacitor columns 5 of each copper bar 3, 4 for the connection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com