Roller type enameled wire surface lubricant coating device and its application

A coating device and lubricant technology, applied in the field of enameled wires, can solve the problems of increasing production costs, stimulation, and fire hazards, and achieve high-efficiency continuity, easy installation and disassembly, and avoid heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

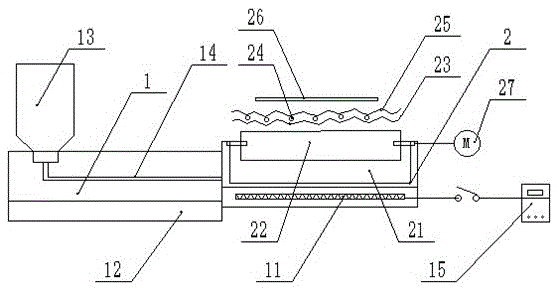

[0024] Such as figure 1 As shown, the roller-type enameled wire surface lubricant coating device of the present invention is particularly suitable for making enameled wires with a diameter of 0.07-1.0 mm, and includes a melting unit 1 that melts solid lubricants into liquid lubricants through heating and is used for enameled wires. The surface of the coating unit 2 is evenly coated with lubricant. Wherein, melting unit 1 comprises heating tube 11, aluminum plate 12, solid lubricant supplier 13 and supply pipeline 14, and aluminum plate 12 is connected with solid lubricant supplier 13, and heating tube 11 is connected with aluminum plate 12; It is used for solid lubricant It is heated and melted to become a liquid lubricant, and flows through the supply pipe 14 to the oil tank 21 of the coating unit 2 . The coating unit 2 includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com