Dispatching control method for batch processor of reentrant manufacturing system

A scheduling control and manufacturing system technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as low utilization efficiency of bottleneck units, lack of manufacturing coordination of equipment units, and separation of assumptions, etc., to meet production scheduling needs , realize the effect of convenience and simple concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further:

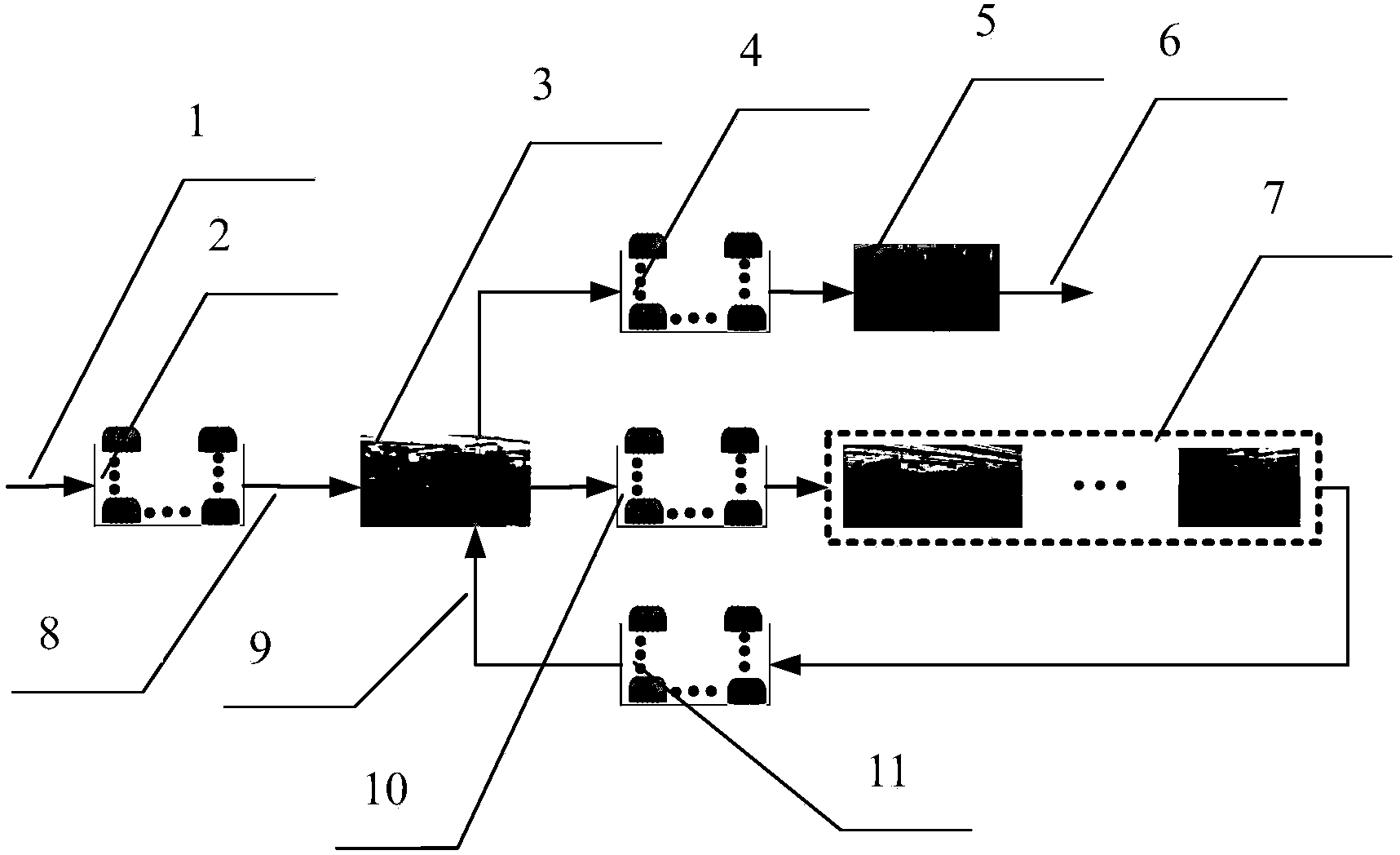

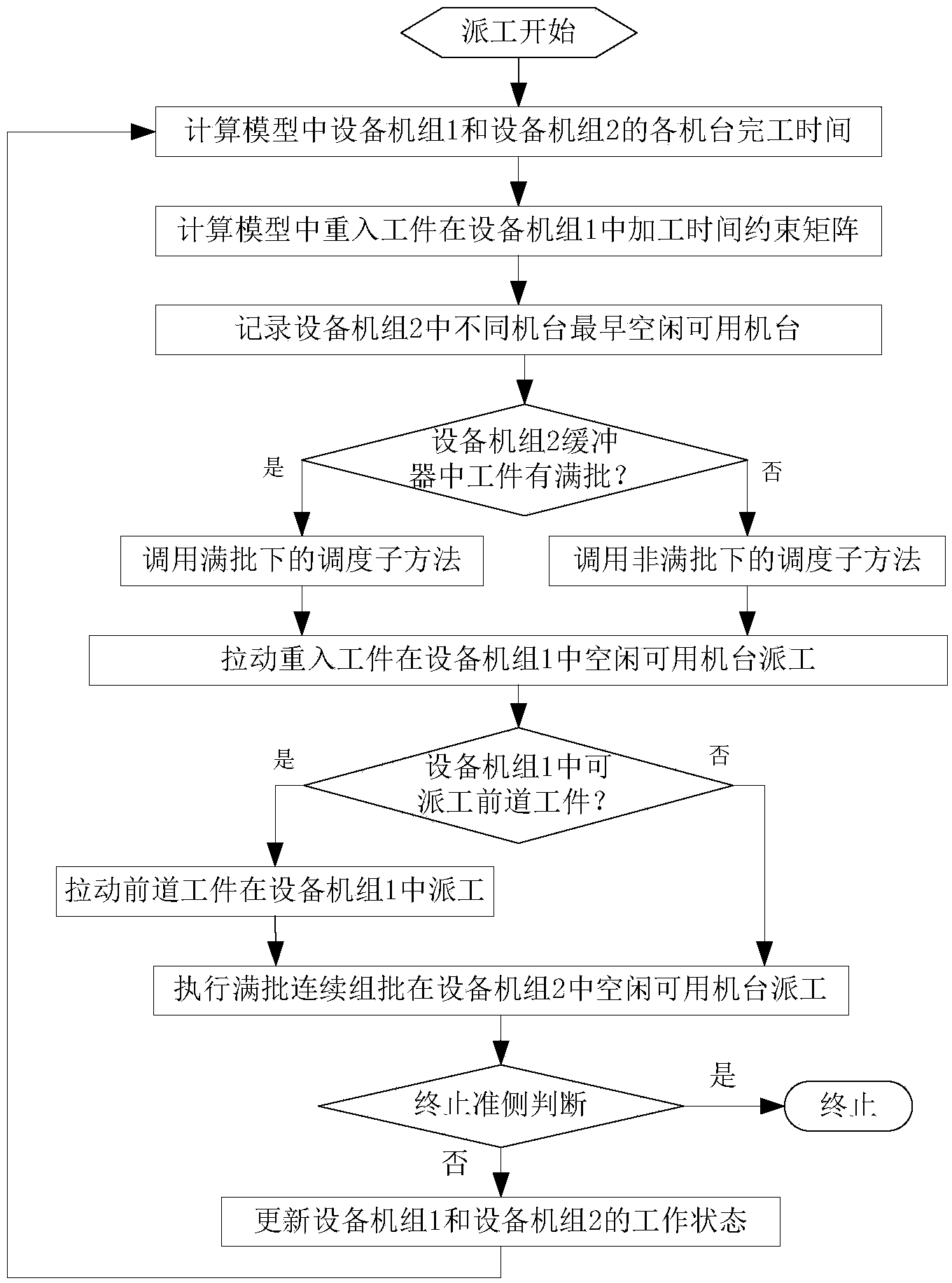

[0037] refer to figure 1 , a typical research model diagram of a reentrant manufacturing system, including input 1, buffer 1 2, equipment unit 1 3, buffer 2 4, equipment unit 2 5, output 6, other equipment units 7, and front-end workpieces 8, Reentry Workpiece 9, Buffer Three 10 and Buffer Four 11. Product processing flow: input 1 → enter buffer 1 2 → front workpiece 8 → equipment unit 1 3 → buffer 3 10 → other equipment unit 7 → buffer 4 11 → re-enter workpiece 9 → equipment unit 1 3 → buffer Two 4→equipment unit two 5→output 6. Among them, equipment unit one 3 is a reentrant equipment unit, which is the equipment unit of the previous process of equipment unit two 5 and other equipment units 7, and can process reentrant workpieces 9 and previous workpieces 8; equipment unit two 5 is the batch processor. There is a maximum stagnation waiting time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com