Single-tube-bundle split solid heat accumulation heat exchanger

A heat exchanger and heat storage technology, which is applied in the direction of heat storage heat exchanger, heat exchanger type, indirect heat exchanger, etc., can solve the problem of high cost, complex structure of heat storage and heat release system, heat exchanger Large volume and other problems, to avoid corrosion, reduce initial investment and operating costs, uniform heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

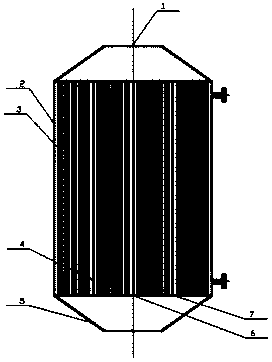

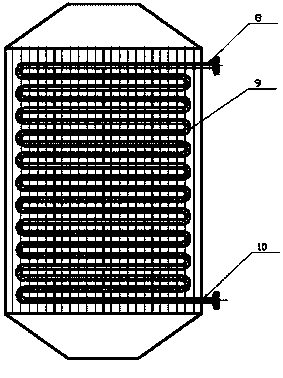

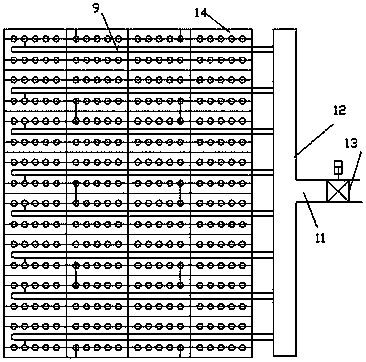

[0041] Such as figure 1 As shown, a regenerative heat exchanger for utilizing waste heat in the cement production process, the heat exchanger includes a low-temperature working fluid tube bundle 9, a high-temperature flue gas inlet 5, a high-temperature flue gas outlet 1, a low-temperature working fluid inlet 10, a low-temperature working fluid The mass outlet 8 and the housing 2, the heat exchanger housing 2 is provided with a plurality of heat storage materials 14, and the plurality of heat storage materials 14 are stacked together, and the first hole 3 and the second hole 3 are arranged in each heat storage material 14. Holes, the first hole 3 and the second hole are intersected, the cryogenic working fluid tube bundle 9 passes through the second hole, the outer diameter of the cryogenic working medium tube bundle 9 is equal to the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com