Light source module and backlight module

A light source module and backlight module technology, which is applied in the direction of light source, electric light source, slender light source, etc., can solve problems such as easy to produce deviation and affect the optical quality of the area, so as to improve the uniformity of light output, simplify the assembly process, and reduce optical darkness. zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

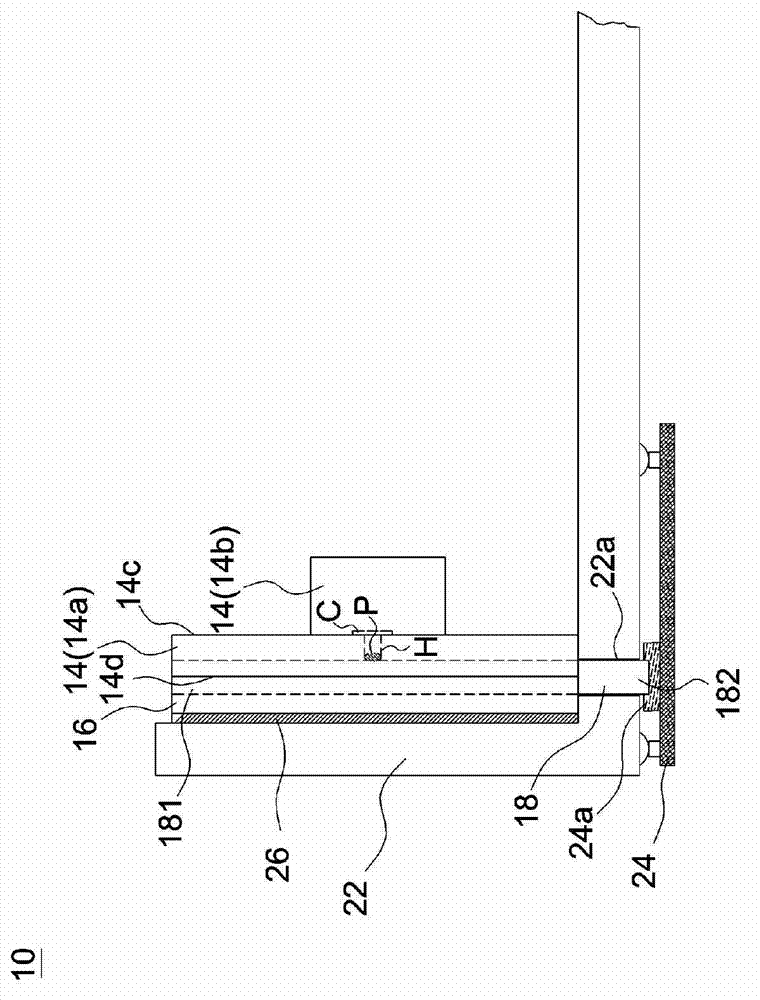

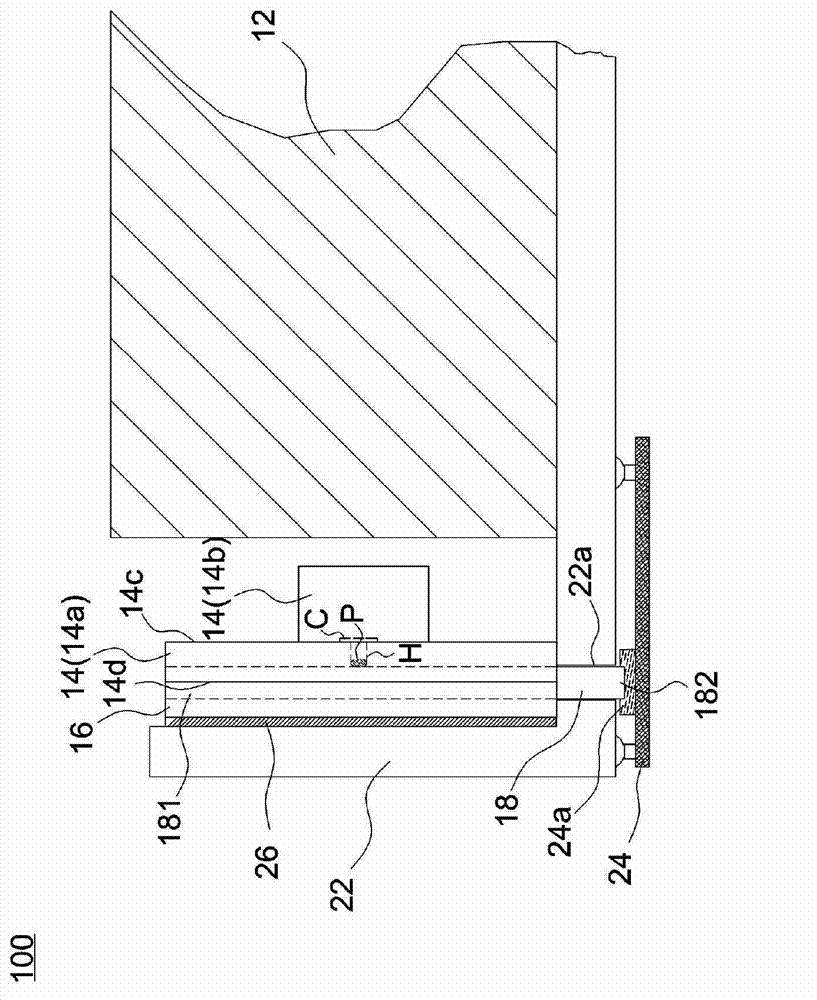

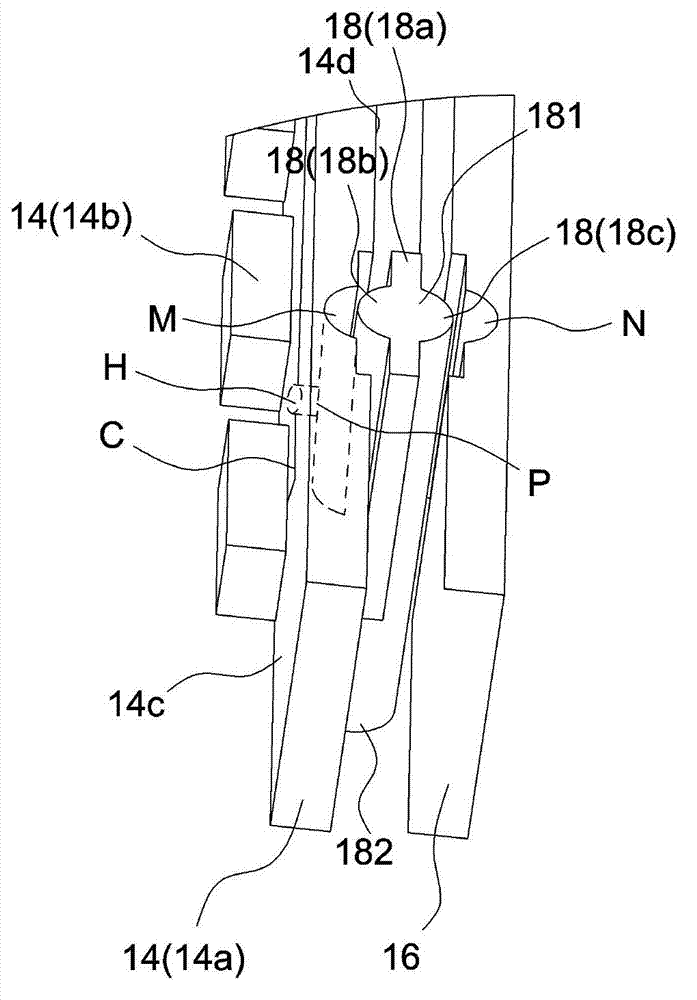

[0062] Figure 1A is a schematic diagram of a light source module according to an embodiment of the present invention, Figure 1B It is a schematic diagram of a backlight module according to an embodiment of the present invention. Please refer to Figure 1A and Figure 1B , a light source module 10 includes an LED strip 14 , a heat sink 16 , a conductive block 18 and a power circuit board 24 . exist Figure 1BAmong them, a backlight module 100 includes a light guide plate 12 and a light source module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com