Pilot plant sluice valve

A pilot-operated, gate valve technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of hidden welding seams and large volume, and achieve the effect of compact structure, small volume, and reduced opening torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

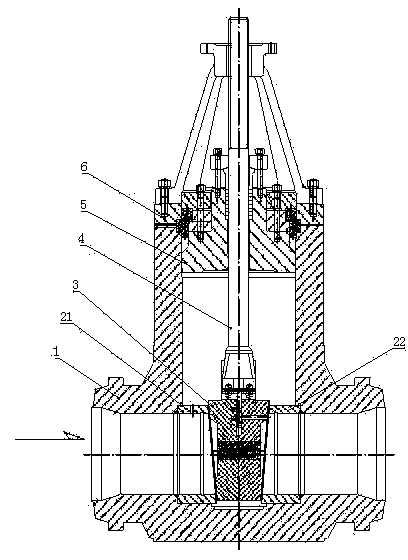

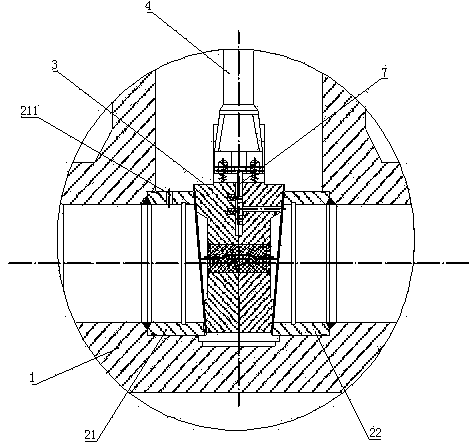

[0024] like figure 1 As shown, it mainly includes a valve body 1, a left valve seat 21, a right valve seat 22, a gate plate 3, a valve stem 4, a valve cover 5, and a gland 6.

[0025] The left valve seat 21 and the right valve seat 22 are welded on the liquid inlet side and the liquid outlet side of the flow channel at the bottom of the valve body 1, and a gate plate 3 that can cooperate with the valve seat 2 to realize the opening and closing of the valve is built in the middle cavity of the valve body. The plate 3 is connected with the lower end of the valve rod 4 extending from the top of the valve body 1 into the middle cavity, and the valve cover 5 is installed on the upper part of the middle cavity of the valve body 1, and the valve cover 5 is connected by bolts by a gland 6 fixed on the upper end surface of the valve body 1.

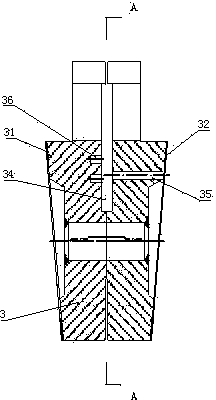

[0026] In the present invention, the pilot-operated power station gate valve also includes an auxiliary gate 7 installed on the top of the gate 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com