Elastic wedge-caulking type flat gate valve

A flat gate valve, wedge type technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the wear of the sealing surface of the gate and the sealing surface of the valve seat, affect the sealing performance and service life of the product, and cannot be disconnected in time, etc. problems, to achieve the effect of reliable sealing performance, long service life and light opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

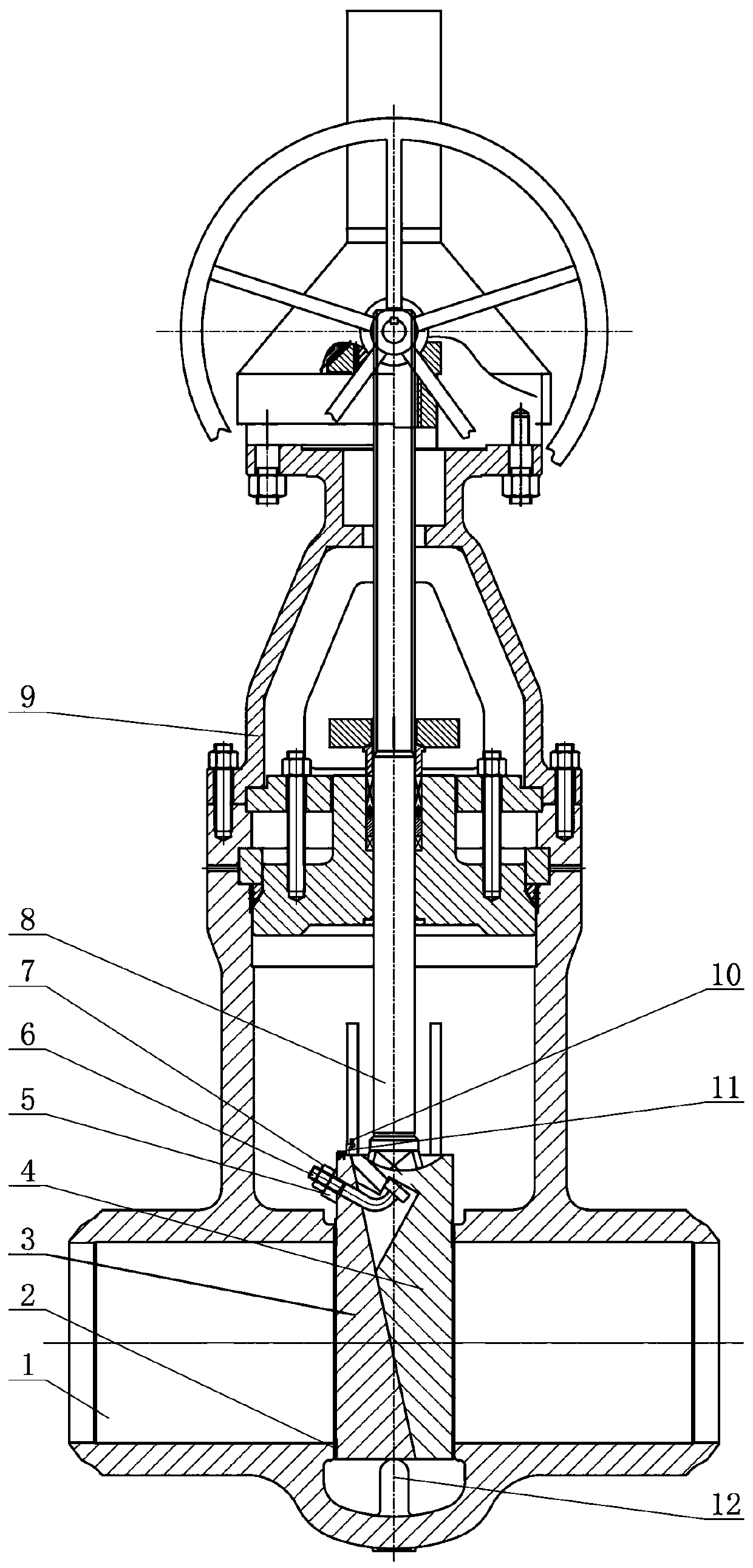

[0010] Such as figure 1 The elastic wedge-tight slab gate valve shown includes a valve body 1, a valve seat 2, a gate plate, a valve stem 8, and a valve cover 9. The gate plate is composed of a main gate plate 4 and an auxiliary gate plate 3. The main gate plate 4 and the auxiliary gate plate The gates 3 are in contact with each other using inclined surfaces. The center of the upper end of the main gate 4 is connected to the lower end of the valve stem 8. The main gate 4 is fixedly connected to the axial direction of the valve stem 8, and radially movable relative to the valve stem 8. A limit plate 11 fixedly connected to the auxiliary ram 3 is provided above the main ram 4, and a limit adjusting screw 10 is provided on the limit plate 11, and the limit adjusting screw 10 axially adjusts the main ram 4 and the auxiliary ram 3 The radial eccentric movement distance between them, the axial adjustment mentioned here refers to the adjustment along the direction of the centerline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com