Hoisting steel belt for elevator and elevator hoisting system including the hoisting steel belt

A steel belt and elevator technology, applied in the elevator field, can solve the problems of inability to achieve slippage, increased wear of the lifting steel belt, inconsistent force, etc., to solve the problem of deviation and uneven force, reduce vibration and noise, The effect of strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

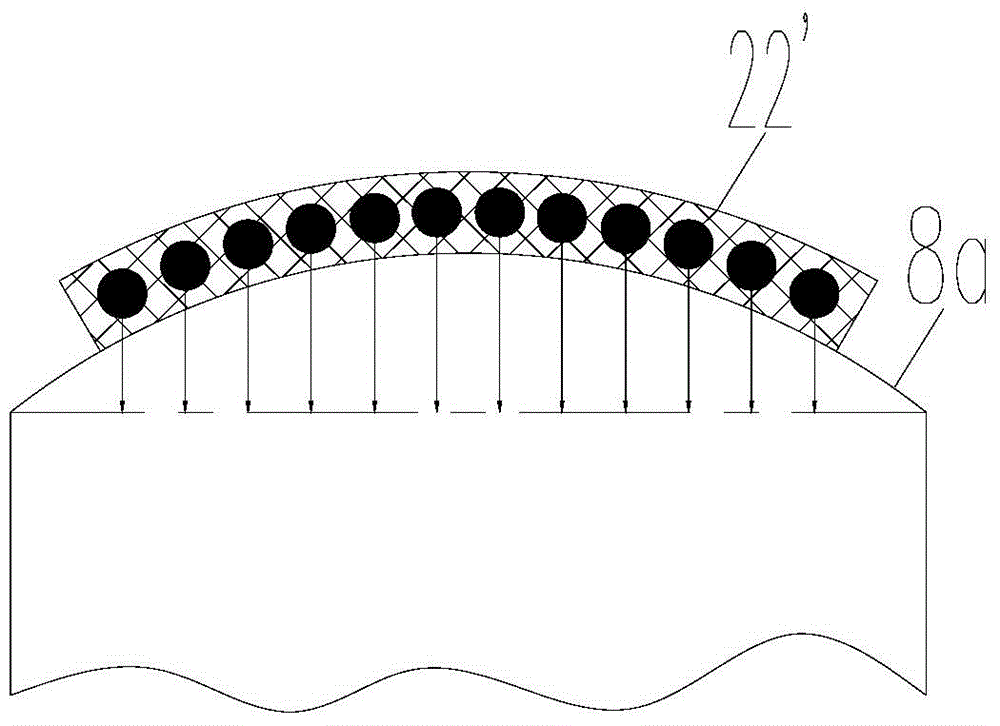

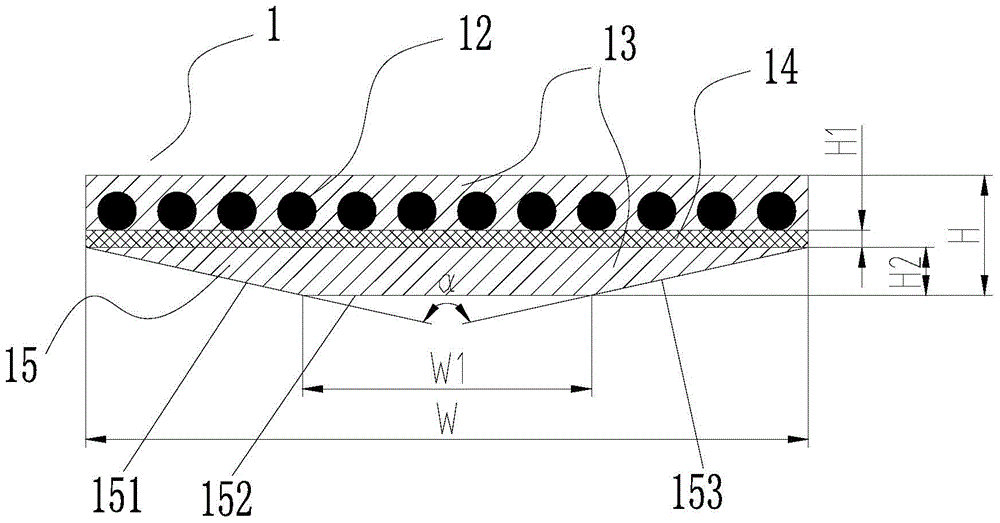

[0040] Such as figure 2 As shown, the hoisting steel belt 1 in this embodiment is composed of multi-strand steel wire ropes 12 and a wrapping layer 13 that wraps each steel wire rope 12 into one. The material of the wrapping layer 13 is polyurethane. The multi-strand steel wire ropes 12 are arranged side by side in a plane, and a reinforcement layer 14 of a mesh structure is arranged in the wrapping layer 13 on the lower side of the plane formed by the multi-strand steel wire ropes 12, and polyurethane is filled in the mesh structure of the reinforcement layer 14. The reinforcing layer 14 is made of aramid fiber material, and the thickness H1 is 0.7 mm. The mesh of the reinforcing layer 14 can be diamond-shaped, the smallest part of the mesh is not less than 3 mm, and the largest part of the mesh skeleton is not larger than 8 mm.

[0041] The lifting steel belt 1 is bounded by the steel wire rope 12, and the side corresponding to the reinforcement layer 14, which is the rev...

Embodiment 2

[0044] Such as Figure 4 As shown, the guide protrusion 15 of the lifting steel belt 1 of the present embodiment is composed of a left guiding surface 151, a central guiding surface 152 and a right guiding surface 153 connected in sequence, and the width W1 of the central guiding surface 152 is smaller than the width W1 of the entire lifting steel belt 12. W, and the left guide surface 151 and the right guide surface 153 are arranged symmetrically, the central guide surface 152 is a plane, and the left guide surface 151 and the right guide surface 153 are convex arc surfaces (the radius R of the arc surface can be 21.25mm), forming The cross-section of the guide protrusion 15 is close to an isosceles trapezoid. Others are the same as embodiment 1.

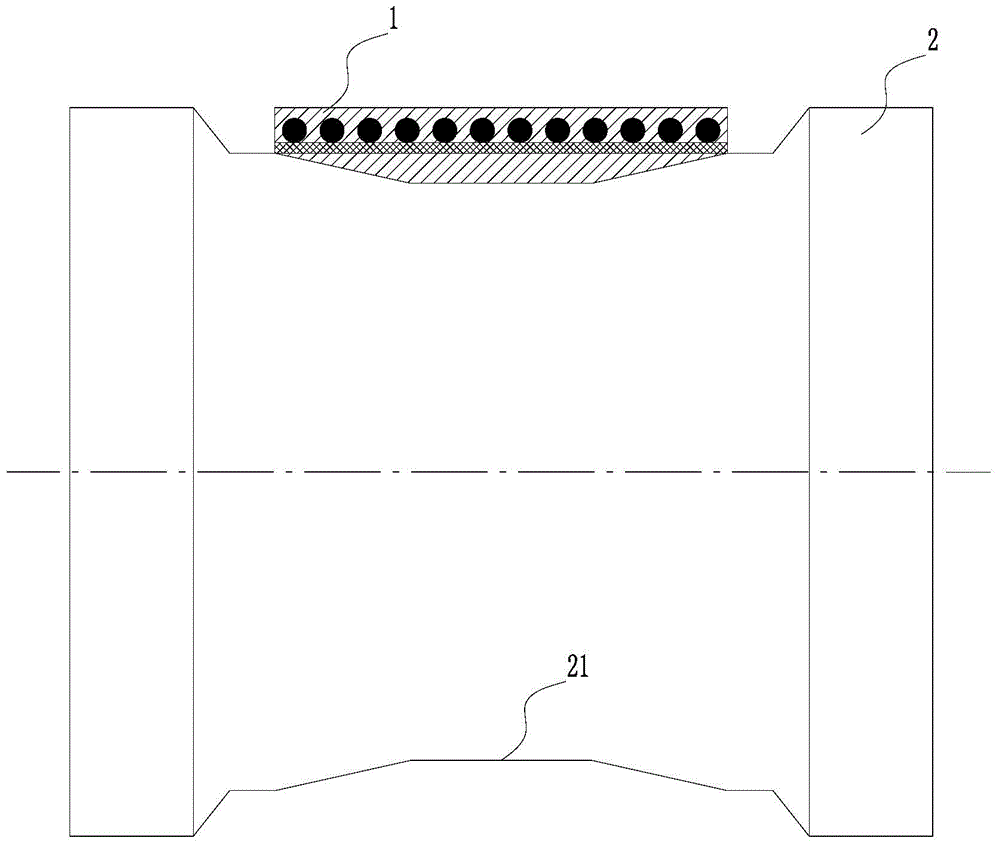

[0045] Such as Figure 5 As shown, the pulley 2 used in conjunction with the lifting steel belt 1 of this embodiment is provided with a guide groove 21 matching the shape and size of the guide protrusion 15 .

Embodiment 3

[0047] Such as Figure 6 As shown, the guide protrusion 15 of the lifting steel belt 1 of the present embodiment is composed of a left guiding surface 151, a central guiding surface 152 and a right guiding surface 153 connected in sequence, and the width W1 of the central guiding surface 152 is smaller than the width W1 of the entire lifting steel belt 12. W, and the left guide surface 151 and the right guide surface 153 are arranged symmetrically, the central guide surface 152 is a convex arc surface (the radius R of the arc surface can be 21.25mm), and the left guide surface 151 and the right guide surface 153 are planes, forming The cross-section of the guide protrusion 15 is close to an isosceles trapezoid. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com