Closed type solid lock cylinder and lock

A closed, solid-state technology, applied in the field of anti-theft, can solve the problem of poor security of the lock cylinder and achieve the effect of security protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

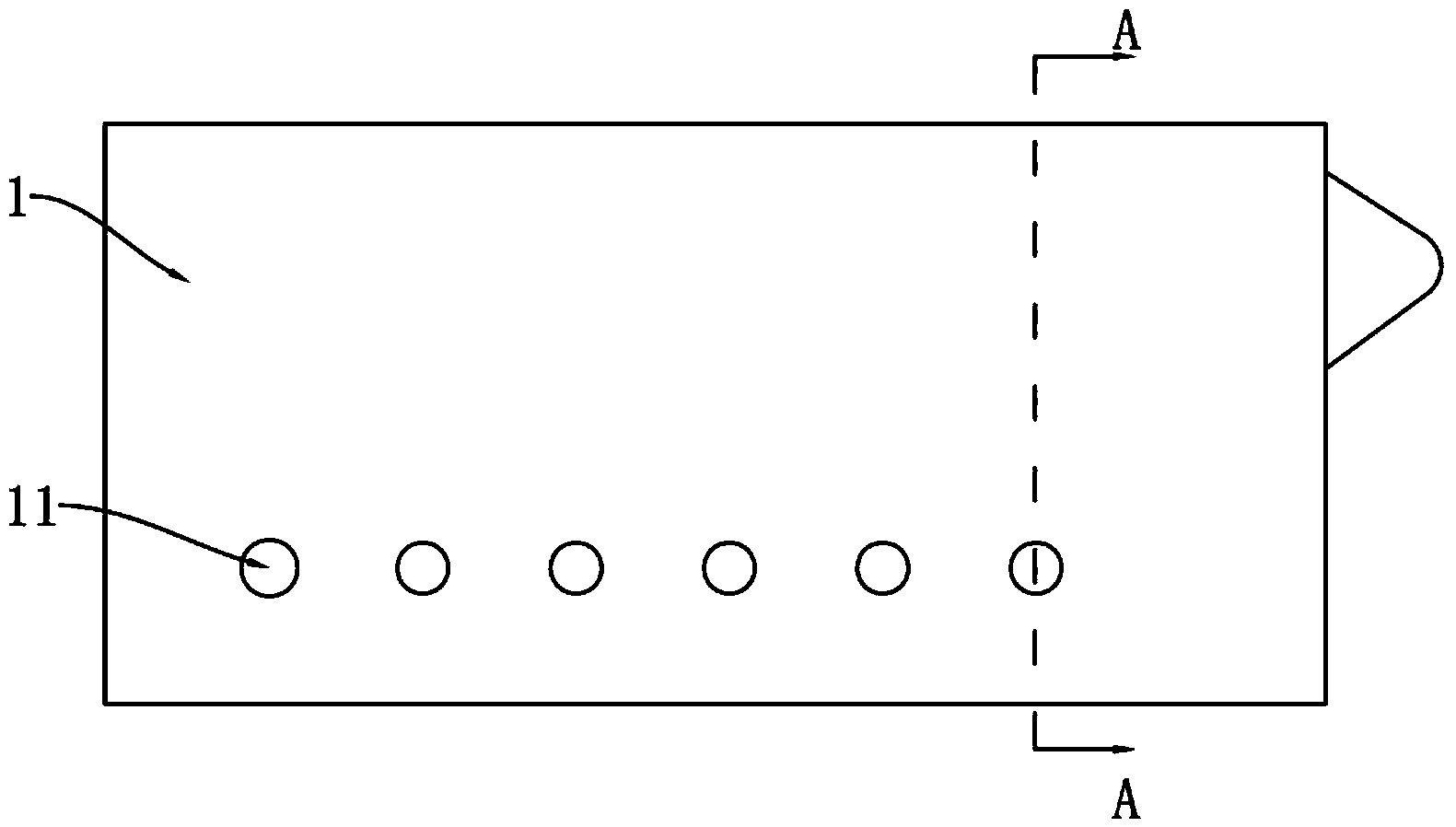

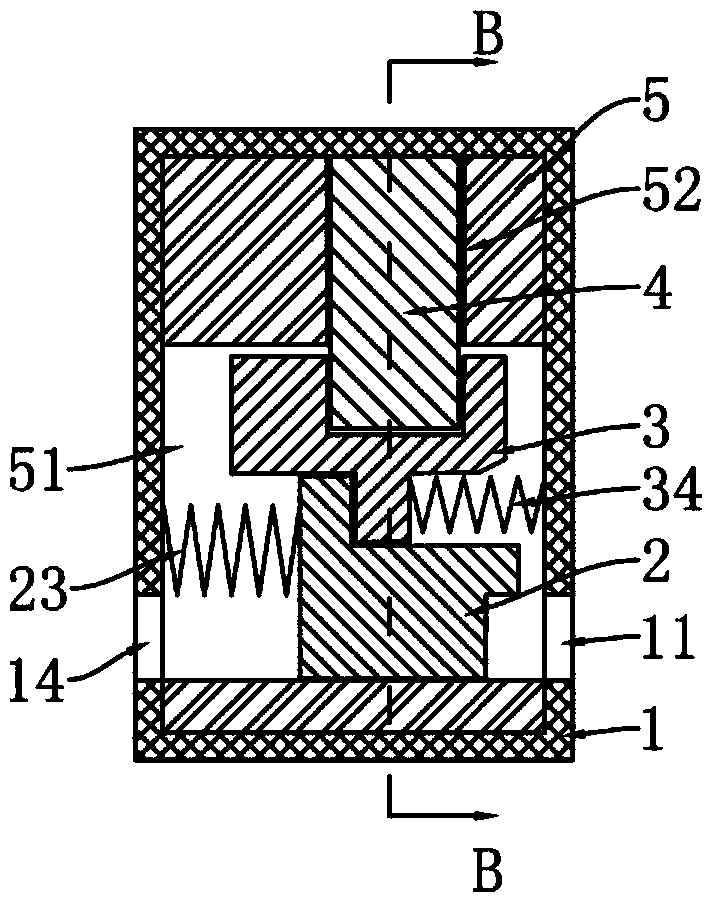

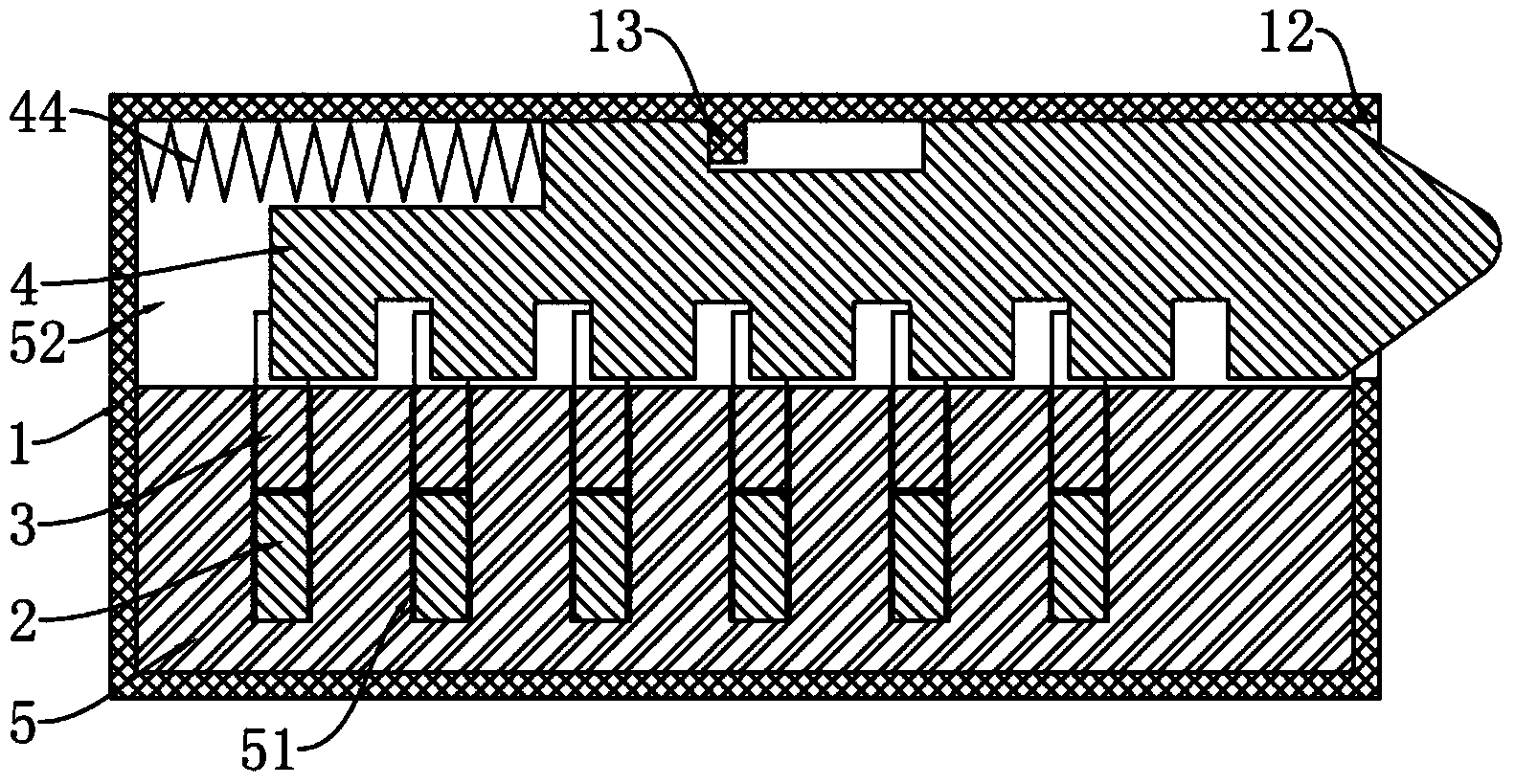

[0033] see Figure 1 to Figure 6 . The closed solid body lock cylinder described in this embodiment is composed of a housing 1 , an unlocking piece 2 , a locking piece 3 , a locking tongue 4 , a base 5 and elastic components.

[0034] The housing 1 is a rectangular parallelepiped, hollow, with a plurality of first keyholes 11 disposed on its front, and a bolt exit hole 12 disposed on one side thereof. A plurality of first keyholes 11 are evenly arranged in a row. In this embodiment, six first keyholes 11 are provided. Of course, other different numbers can also be set. Theoretically speaking, according to this embodiment For the structure of the lock cylinder, the more the number of the first key holes, the higher the safety performance of the lock cylinder.

[0035] The base 5 is provided with a plurality of locking plate sliding grooves 51 and a locking tongue sliding groove 52 , and the locking plate sliding grooves 51 and the locking tongue sliding grooves 52 are partial...

Embodiment 2

[0045] see Figure 7. The basic structure of the lock described in this embodiment is basically the same as that of the lock cylinder described in Embodiment 1, and only the differences will be described below.

[0046] The difference from Embodiment 1 is that the outer end of the lock tongue 4 is set as a vertical apex 43b instead of a horizontal apex; the vertical apex 43b is like a vertically placed prism. The longitudinal apex 43 b comprises two vertical faces extending compared to a line lying on the plane of symmetry of the bolt 4 .

[0047] For the convenience of unlocking on both sides of the door, corresponding to the first keyhole 11, six second keyholes 14 are provided on the back side of the housing 1, and the second keyhole 14 and the first keyhole 11 are on two sides. on the opposite side.

[0048] In order to more clearly illustrate the working mode of the lock core or lock in the above two embodiments, the following description will be made in conjunction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com