Quick tower split raft foundation

A technology of split raft and raft foundation, which can be used in infrastructure engineering, construction, etc., and can solve the problems of quality, difficult to guarantee construction period, large amount of concrete pouring and ramming, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

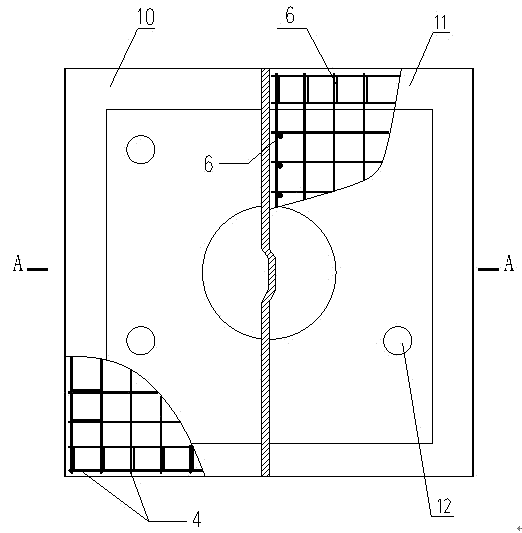

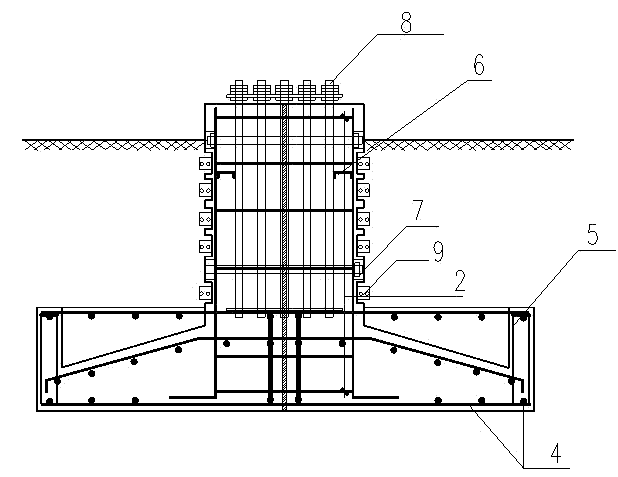

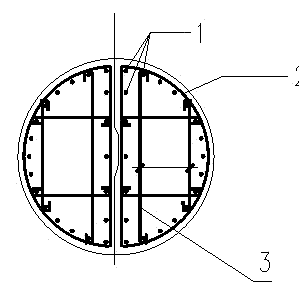

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It can be seen from the accompanying drawings that a pole-tower split raft foundation quick-installation foundation of this program includes a raft foundation, and is characterized in that: the raft foundation is made of raft The raft foundation I10 and the raft foundation II11 are composed of a concrete rectangular base and a concrete semi-column integrated at the upper end respectively, and steel bars are set in the raft foundation I10 and the raft foundation II11. Anchor bolts 8 are arranged in the concrete half cylinder, and hoops 9 are arranged on the surface of the concrete half cylinder. The concrete semi-cylindrical contact surfaces of the raft foundation I10 and the raft foundation II11 are engaged. The steel bars in the concrete semi-cylinder are composed of vertical main bars 1, spiral bars 2 spirally wound around the main ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com