Construction method of pre-buried steel purlin plugging head system for underground diaphragm wall

An underground diaphragm wall and construction method technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as construction difficulties, inaccurate positioning, and insufficient shear resistance of anchor bars, and achieve simple on-site construction, The effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

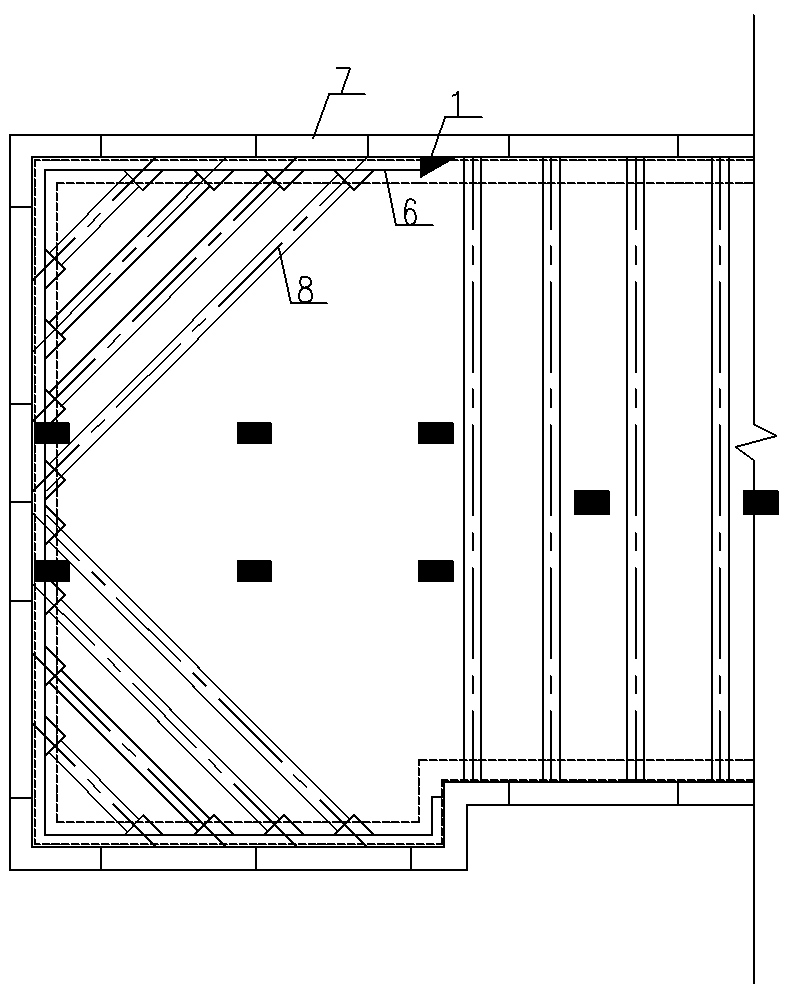

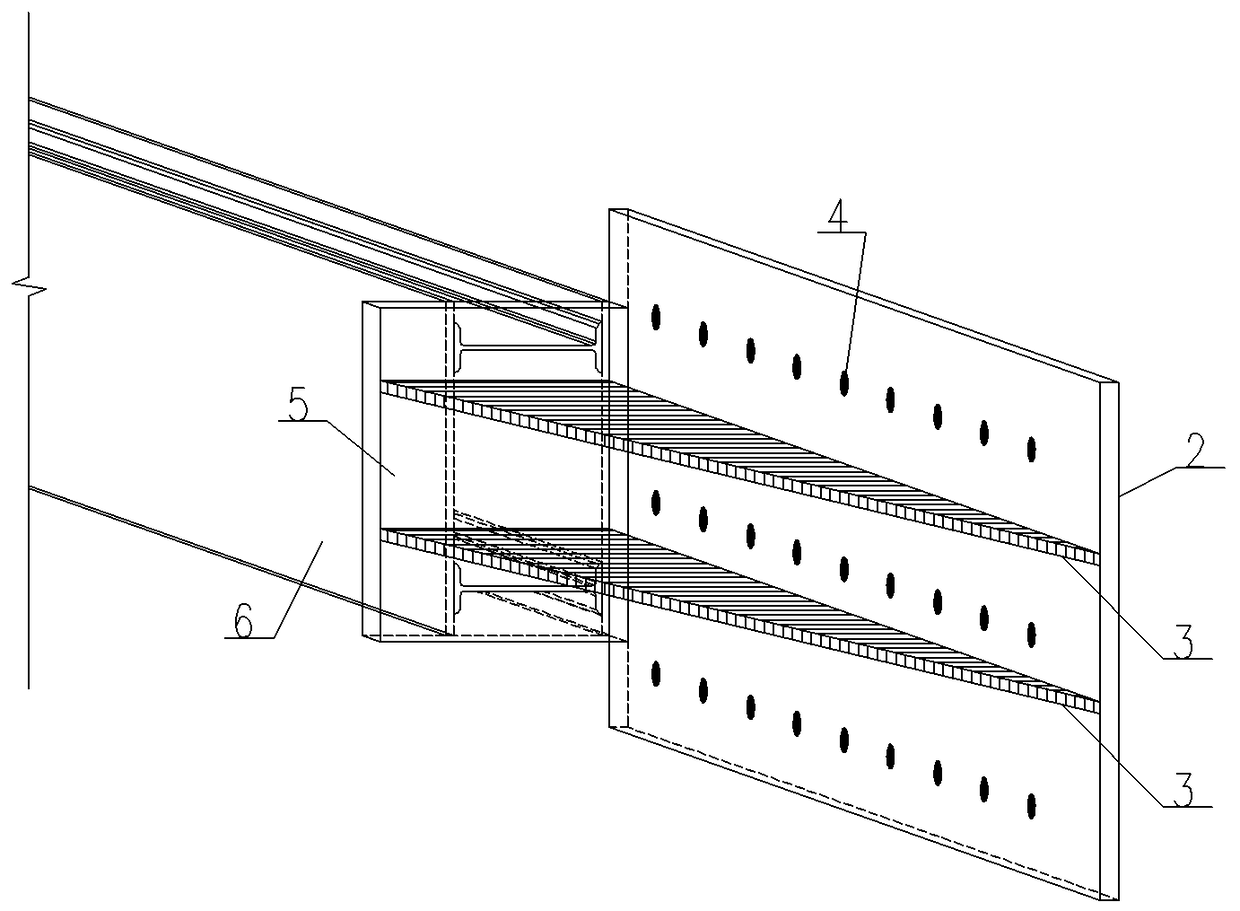

[0028] The present invention relates to the pre-embedded steel purlin plug system for the underground diaphragm wall, which is a new type of shear-resistant plug system combined by welding the pre-embedded steel plate and the steel purlin. A force-transmitting steel plate 5 perpendicular to and vertical to the steel purlin 6 is arranged on the outside. The surface of the ground connection wall 7 on the outside of the force-transmitting steel plate 5 is provided with steel purlin pre-embedded steel plates 2, and the ground connection wall 7 on the inside of the steel purlin pre-embedded steel plate 2 is provided with shear anchors perpendicular to the steel purlin pre-embedded steel plate 2 Rib 4, the outer side of the pre-embedded steel plate 2 is provided with a shear steel plate 3 vertical and horizontal to the pre-embedded steel plate 2 of the steel purlin, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com