Hand sample color imitation process for cotton knitted fabric

A cotton knitted fabric and dithering technology, which is applied in the field of small sample dithering technology, can solve the problems of increased production cost, decreased product competitiveness, and high color correction rate of large samples, and achieves reduced production cost, increased success rate, and improved weight. present effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

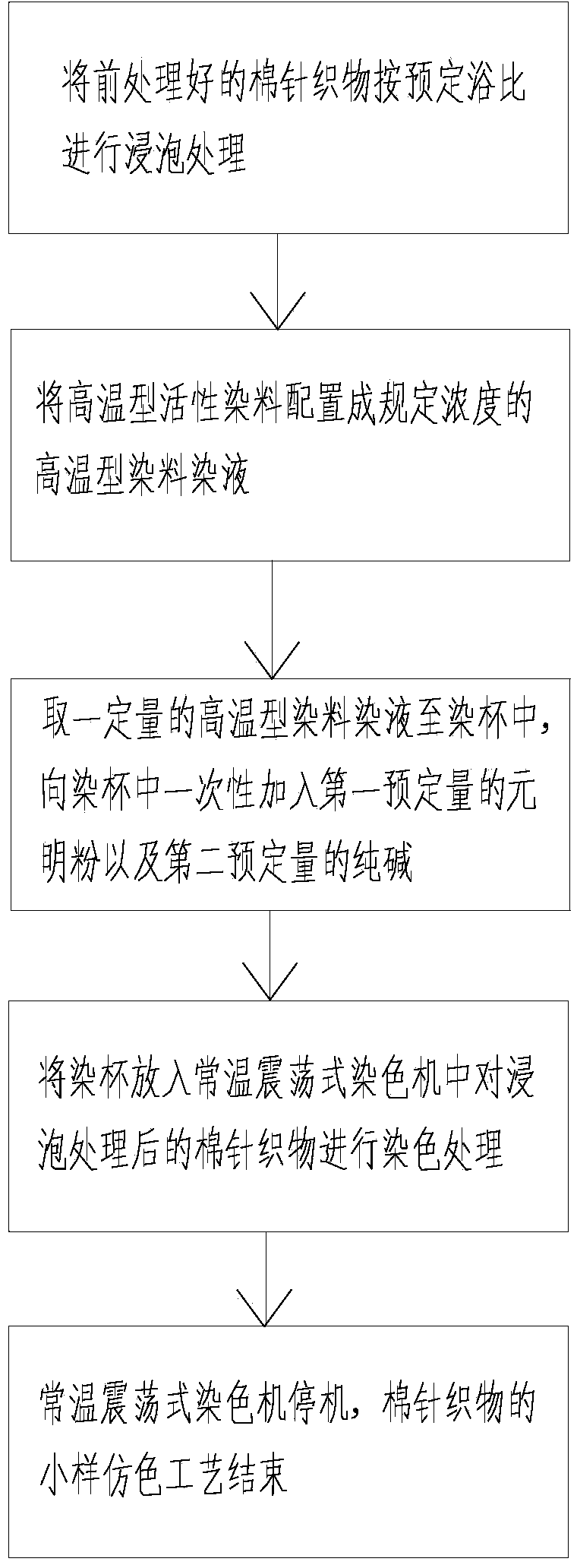

[0038] Such as figure 1 As shown, the sample dithering process of cotton knitted fabrics in this embodiment is dyed for high-temperature reactive dyes, and the process flow is as follows:

[0039] Small sample soaking treatment steps: Accurately weigh several pieces of dry pre-treated cotton knitted fabrics, put the cotton knitted fabrics into a stainless steel cup with a bath ratio of 1:10 for soaking, and then place the stainless steel cup in an induction cooker Heat to 80°C, rinse the cotton knitted fabric with cold water after 10 minutes, wring it out and spread it flat to make the humidity consistent.

[0040] Dyeing solution configuration steps: use high-temperature reactive dyes to prepare a high-temperature dyeing solution with a specified concentration, and the specific steps are as follows:

[0041] (1) Accurately weigh the high-temperature reactive dye according to the prescription and add it to a 50ml beaker, dissolve the dye with warm water at 40°C and stir well ...

Embodiment 2

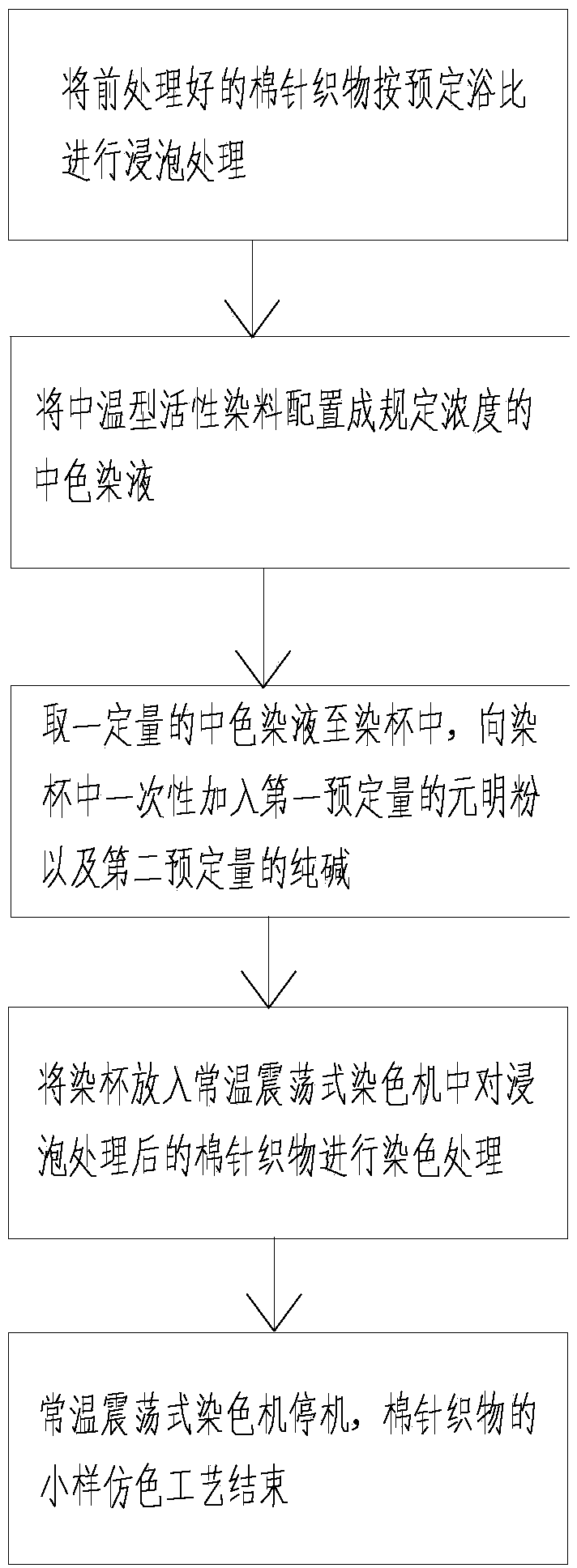

[0052] Such as figure 2 As shown, the sample dithering process of cotton knitted fabrics in this embodiment is aimed at dyeing neutral color with medium-temperature reactive dyes, and the process flow is as follows:

[0053] Small sample soaking treatment steps: Accurately weigh several pieces of dry pre-treated cotton knitted fabrics, put the cotton knitted fabrics into a stainless steel cup with a bath ratio of 1:10 for soaking, and then place the stainless steel cup in an induction cooker Heat to 80°C, rinse the cotton knitted fabric with cold water after 10 minutes, wring it out and spread it flat to make the humidity consistent.

[0054] Dye liquor configuration steps: Use medium-temperature reactive dyes to prepare a neutral dye liquor with a specified concentration. The specific steps are as follows:

[0055] (1) Accurately weigh the medium-temperature reactive dye according to the prescription and add it to a 50ml beaker, dissolve the dye with warm water at 50°C and st...

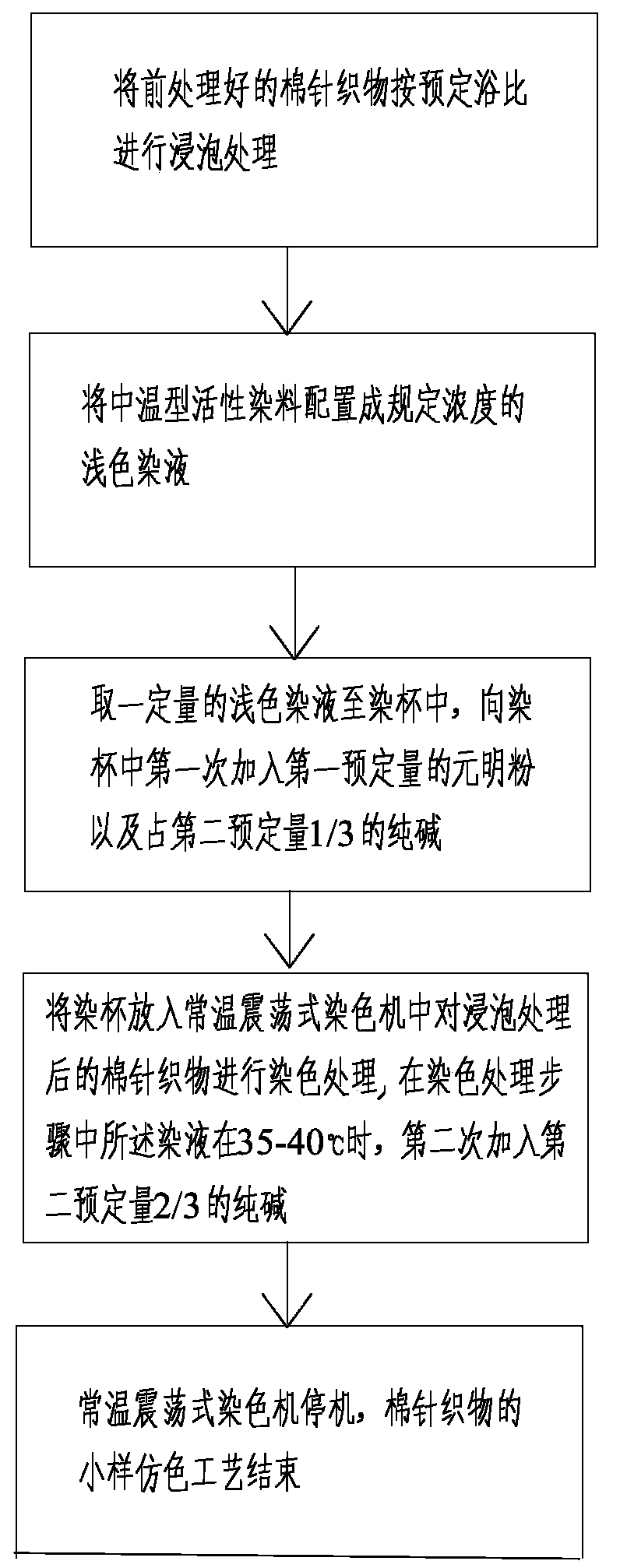

Embodiment 3

[0066] The small sample dithering process of cotton knitted fabrics in this embodiment is aimed at dyeing dark colors with medium-temperature reactive dyes. A dark dye solution with a specified concentration, and the dark dye solution is then subjected to an auxiliary agent addition step and a dyeing treatment step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com