Method of preparing 4-androstenedione by fermentatively degrading phytosterol by virtue of single water phase system

A technology of phytosterols and androstenedione, which is applied in the field of microbial transformation of steroidal drugs, can solve problems such as environmental pollution and product extraction difficulties, and achieve the effects of less environmental pollution, fewer types of solvents, and lower difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

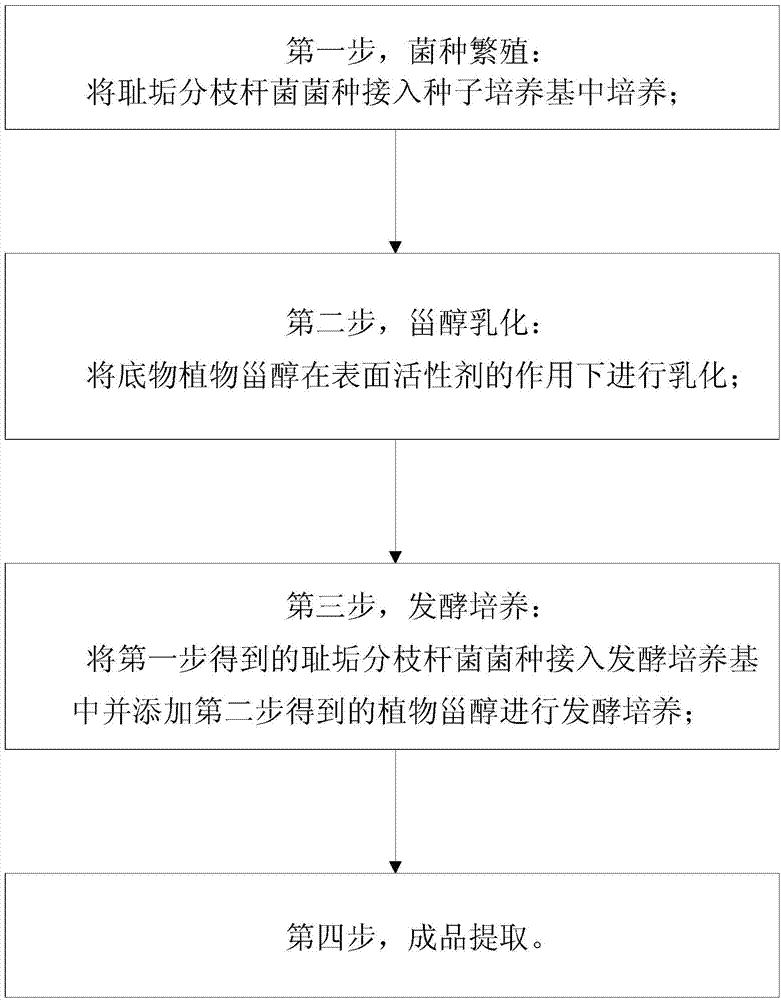

Image

Examples

Embodiment 1

[0037] A method for preparing 4-androstenedione by fermenting and degrading phytosterols in a single aqueous phase system, comprising the steps of:

[0038] The first step, strain propagation: the concentration of 10 7 The Mycobacterium smegmatis bacterial classification of each / ml inserts and cultivates in the culture jar that seed medium is housed with 10% inoculation amount, comprises the component of following concentration in the seed medium: glucose 10g / L, K 2 HPO 4 0.6g / L, MgSO 4 ·7H 2 O0.5g / L, (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O0.05g / L, CaCO 3 5.0g / L and citric acid 2.5g / L, the pH of the seed medium is 6.0;

[0039] The second step, sterol emulsification:

[0040] The substrate phytosterol is emulsified under the action of emulsifier Tween 80, and the emulsification temperature is 60°C;

[0041] The third step, fermentation culture:

[0042] The OD of the culture medium in the first step 600 At 20 o'clock, with 50% inoculum size, it is inserted in the fermenter ...

Embodiment 2

[0049] Change the emulsification temperature in Example 1 to 50°C, and the rest of the operations are the same as in Example 2.

[0050] Test results: the conversion rate of phytosterol was 89.6%, the final potency was 13.44g / L, and the purity of the obtained 4-androstenedione was greater than 99.0%.

Embodiment 3

[0052] Change the emulsification temperature in Example 1 to 70°C, and the rest of the operations are the same as in Example 2.

[0053] Test results: the conversion rate of phytosterol was 84.3%, the final titer was 12.65g / L, and the purity of the obtained 4-androstenedione was greater than 99.0%. Comprehensive analysis of Examples 1-3 shows that the most preferred emulsification temperature is 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com