A submersible aerator with grinding device

A technology for aerators and submersible motors, applied in water aeration, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as water inlet clogging, and achieve the effect of improving clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

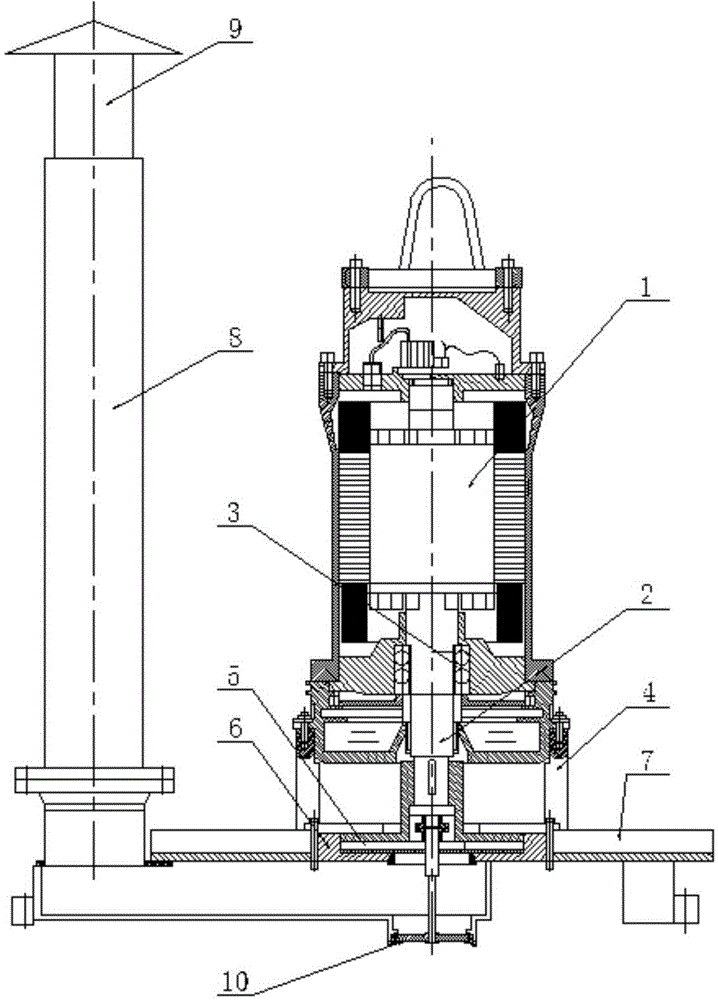

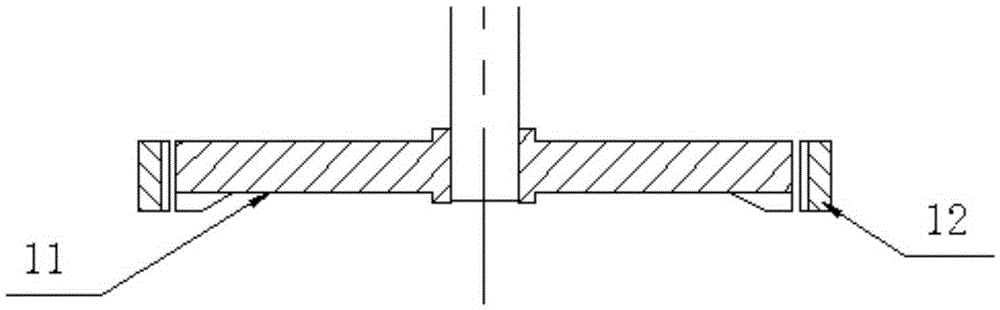

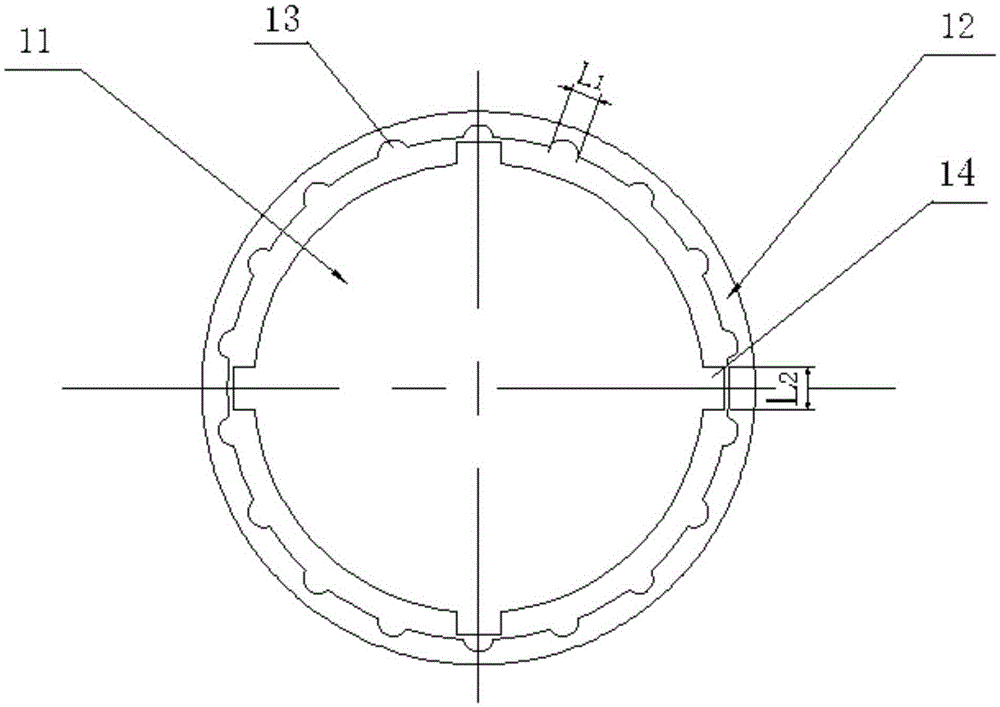

[0017] figure 1 Shown is a schematic structural view of the aerator with a crushing and grinding device according to the present invention. The aerator includes a submersible motor 1 , a hollow drive shaft 2 , an elastic coupling 3 , a body 4 , an impeller 5 , a mixing chamber 6 , a mixing vane 7 , an injection pipe 8 , and an air intake pipe 9 . A grinding device 10 is arranged at the water inlet of the aerator. The submersible motor 1 is connected to the hollow drive shaft 2 through an elastic coupling 3; the impeller 5 is installed on the other end of the hollow drive shaft 2, and the shaft end of the impeller 5 is connected to the shaft of the grinding device 10 through the elastic coupling 3, The grinding device 10 is installed at the shaft end water inlet of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com