Method and device for preparing active carbon by white spirit grains

A technology for preparing activated carbon and white distiller's grains, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as easy bridging, and achieve the effects of reducing moisture content, high economic benefits, and promoting industrial upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

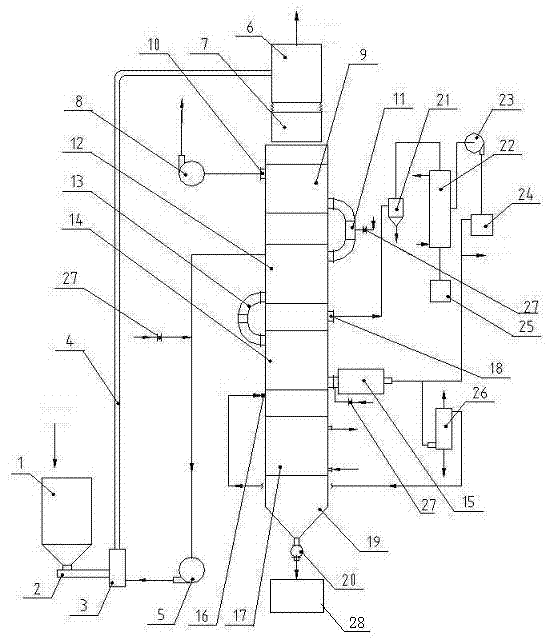

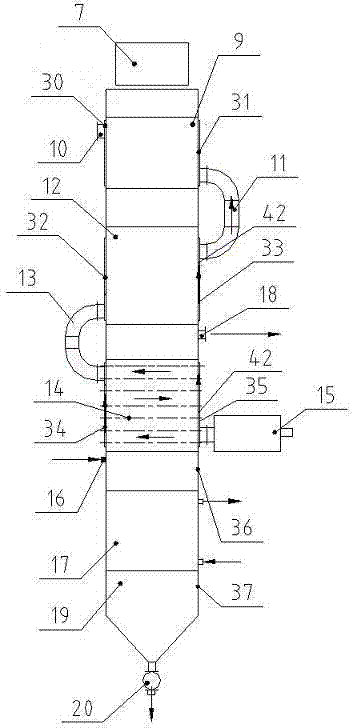

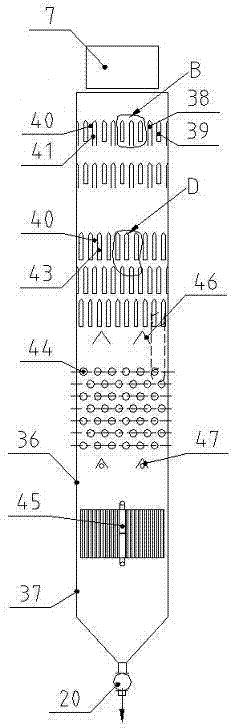

[0033] Such as Figure 1~Figure 5The device for preparing activated carbon from distiller's grains shown includes an airflow drying feeding system, an integrated furnace, a combustion furnace 15, and a gas boiler 26. The integrated furnace includes a drying section 9, a carbonization section 12, and an activation section arranged sequentially from top to bottom. Section 14, cooling section 17, discharge section 19, and the transition section between each section, described drying section 9, carbonization section 12, activation section 14, cooling section 17 are respectively provided with heat exchange elements; 9 is provided with a drying section flue gas main passage 30, a drying section flue gas main passage 31, and the carbonization section is provided with a carbonization section flue gas main passage 32, a carbonization section flue gas main passage 33, and the activation The section 14 is provided with an activation section flue gas main duct 34 and an activation section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com