Variable color thermoprinting membrane and making method thereof

A manufacturing method and bronzing film technology, which are applied in the directions of copying/marking methods, chemical instruments and methods, printing, etc., can solve the problems of complex manufacturing process, expensive spacer layer process and high cost, and achieve enhanced visual recognition effect and efficient processing method. , the effect of fewer production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one: the hot stamping film of multiple discoloration areas is arranged on the same substrate

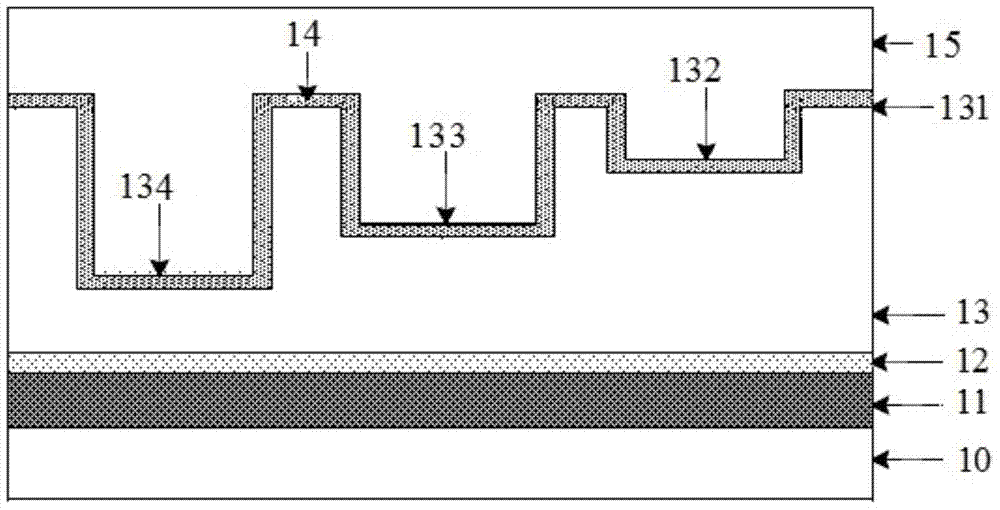

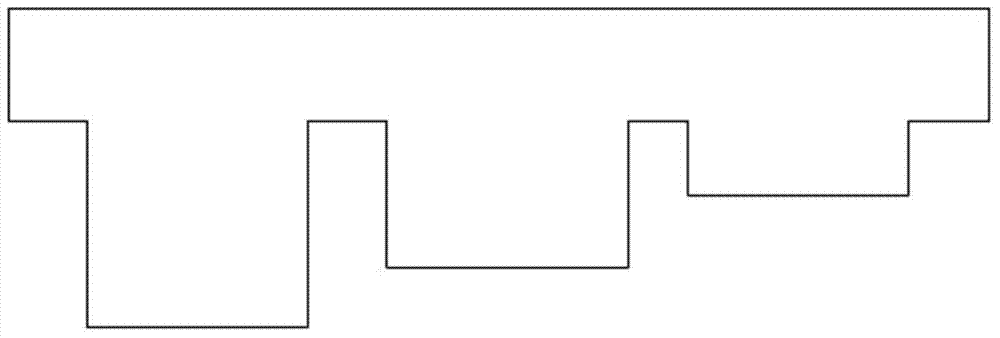

[0047] The color-changing hot stamping film described in this embodiment is as follows: figure 1 As shown, it includes a base film 10 , a release layer 11 , a semi-transparent and semi-reflective metal layer 12 , an information medium layer 13 , a full-inversion metal layer 14 and a hot melt adhesive 15 . Wherein the information medium layer 13 is a plastically variable organic medium coating, and its two opposite surfaces are respectively covered by the semi-transparent and semi-reflective metal layer 12 and the full-inversion metal layer 14, and the surface intersecting with the full-inversion metal layer 14 is set There are various steps with different heights (four kinds of steps 131, 132, 133, 134 are shown in the figure), and the surface intersecting with the transflective metal layer 12 is a plane. The semi-transparent and semi-reflective metal layer 12, the...

Embodiment 2

[0051] The color-changing hot stamping film described in this embodiment is as attached Figure 5 As shown, it includes a base film 20 , a release layer 21 , an information medium layer 23 , a semi-transparent and semi-reflective metal layer 22 , a full-reflective metal layer 24 and a hot melt adhesive 25 . Compared with Embodiment 1, in this embodiment, the steps of the information medium layer 23 are formed on the surface close to the base film 20 , that is, these steps are covered by the transflective metal layer 22 . However, due to the influence of the production sequence between the various layers of films, it is necessary to first form a layer of information medium layer 23 on the release film 21, then press out the step structure, and then cover the semi-transparent and semi-reflective metal layer 22 on the step, so In this embodiment, the information medium layer 23 remains between the semi-transparent and semi-reflective metal layer 22 and the release layer 21 . Oth...

Embodiment 3

[0053] The color-changing hot stamping film described in this embodiment is as attached Image 6 As shown, it includes a base film 30 , a release layer 31 , an information medium layer 33 , a semi-transparent and semi-reflective metal layer 32 , a full-reflective metal layer 34 and a hot melt adhesive 35 . In this embodiment, the steps of the information medium layer 23 are made inside and covered by the transflective metal layer 32 at the same time. During production, it is only necessary to set the height of the information medium layer 23 coated for the first time to be greater than the maximum height of the indenter on the basis of the second embodiment, and other manufacturing processes and steps are the same as those of the second embodiment. Let me repeat.

[0054] A situation that is easily expanded by this embodiment is that the full-inversion metal layer 34 can be covered on the step. At this time, the order of making is: first nano-coating the release layer 31, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com