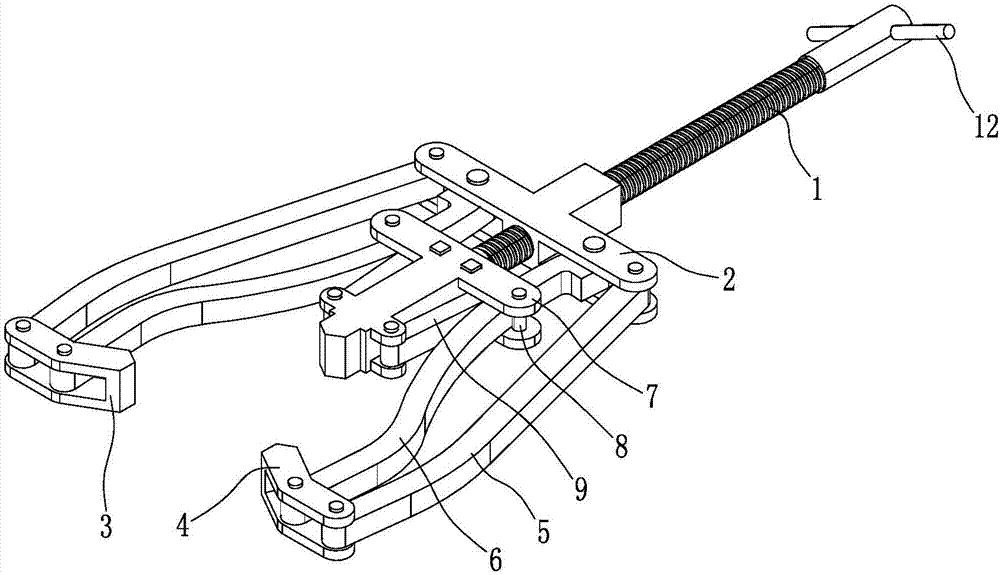

Three-jaw clamp

A technology of three-jaw card and claw card, which is applied in the field of parts assembly, can solve problems such as low assembly efficiency, high labor intensity, and difficult tooth alignment, and achieve the effects of simplifying assembly difficulty, improving assembly efficiency, and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

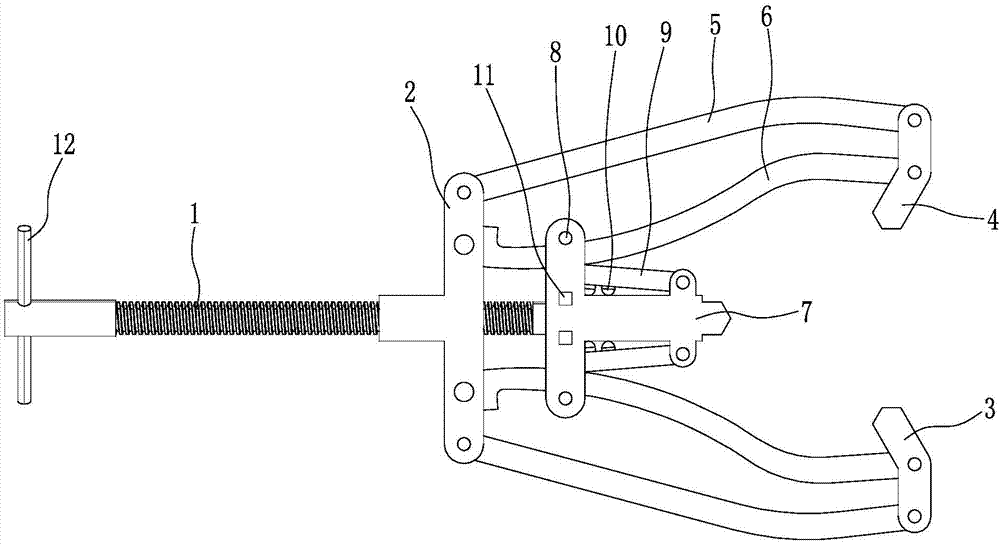

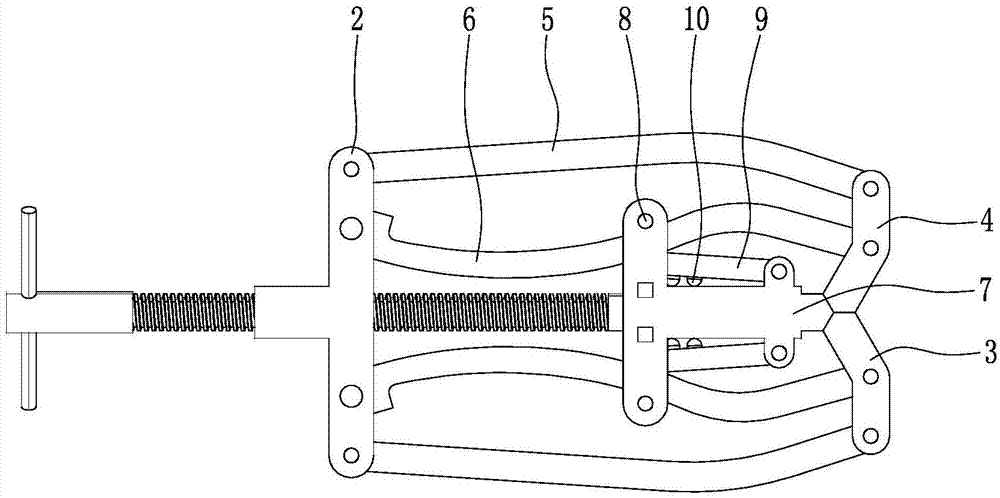

[0015] Such as figure 1 , figure 2 , image 3 As shown, a handle 12 is fixedly worn on the rear end of the lead screw 1 , and the handle 12 is a small cylindrical structure and is perpendicular to the lead screw 1 . The nut cover support 2 is set on the threaded section of the middle section of the leading screw 1, and the two are threadedly matched and can rotate relatively. A first chuck 7 is arranged at the front end of the lead screw 1, and the first chuck 7 is in the shape of a horizontal "earth", and the end of the front end of the first chuck 7 is a pointed structure. The front end of the screw 1 extends into the first chuck 7 from back to front, and the two are in clearance fit. Two locking square pins 11 are arranged side by side in the middle of the rear transverse section of the first chuck 7. The locking square pins 11 are arranged side by sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com