Solid particle thermal expansion vibration composite forming process of car rear axle housing

A technology of solid particles and automobile rear axles, applied in the field of pipe bulging technology, to achieve the effects of reducing mold clamping force, improving formability, and improving relative motion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the drawings and embodiments.

[0040] A thermal expansion and vibration composite forming process for solid particles of automobile rear axle housing includes the following steps:

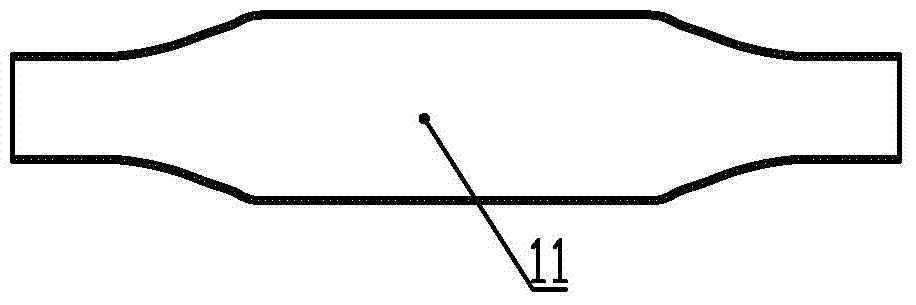

[0041] Step 1, diameter reduction treatment to obtain the necked blank 11:

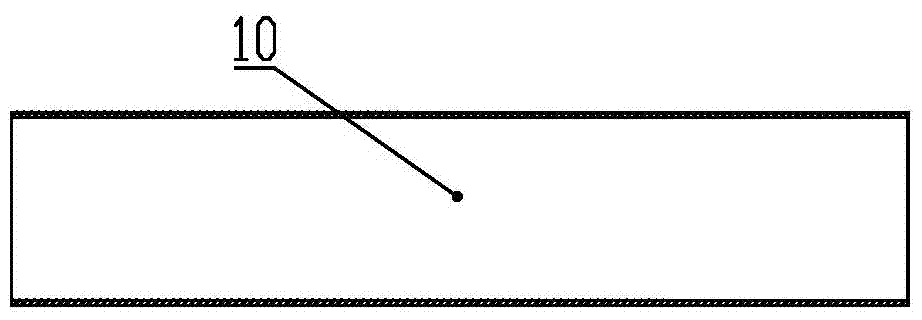

[0042] Reference figure 1 , First select 114*4 seamless steel pipe 10 according to the size of the automobile rear axle housing and bulging requirements, and then carry out four-pass cold-pushing compression treatment, among which, stress relief annealing is carried out after the two-pass diameter reduction is completed ;

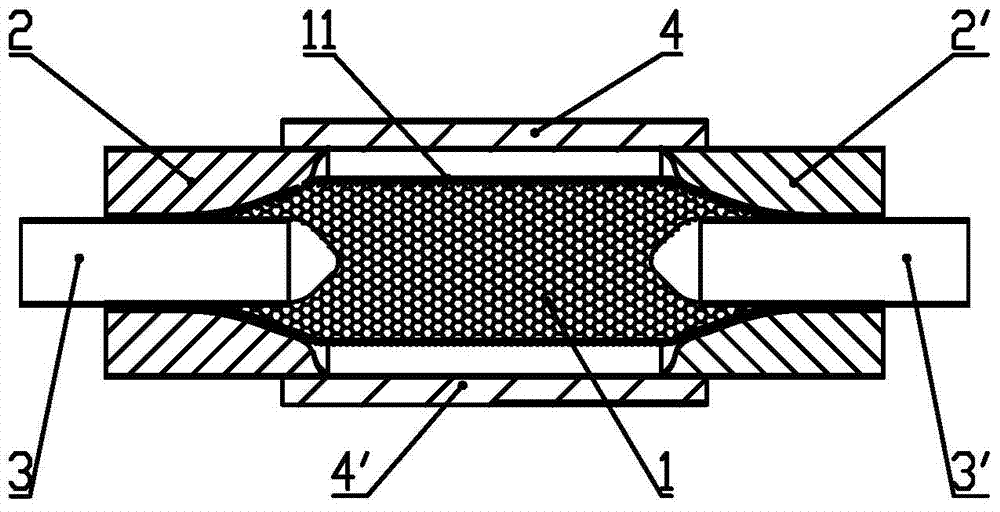

[0043] Step 2. Heating and assembling a bulging mold:

[0044] Reference figure 2 , image 3 , The solid particles that have been run-in in the graphite powder are loaded into the reduced diameter tube 11, the solid particles are selected from the steel ball 1 with a diameter of 1mm, and the left indenter 3 and the right indenter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com