A lower exhaust cyclone separator

A cyclone separator and exhaust pipe technology, which is applied to swirl devices, devices whose axial directions of swirl can be reversed, etc. The effect of reducing blow-by gas, improving removal effect, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

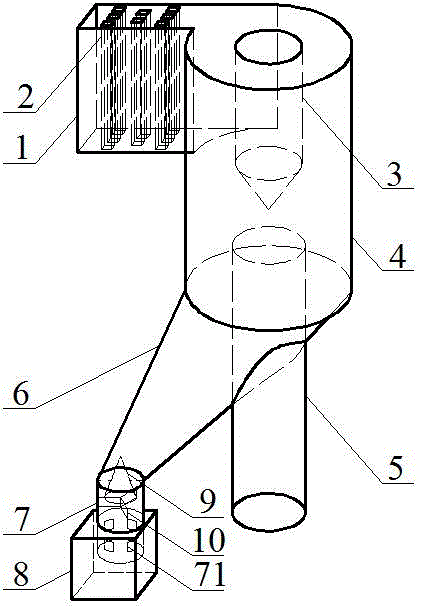

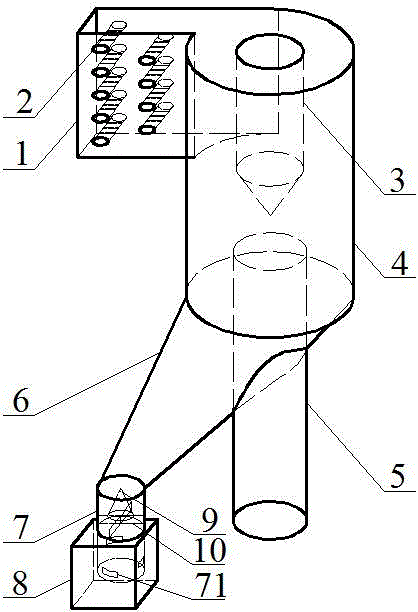

[0019] from figure 1 , figure 2 As can be seen in the figure, a lower exhaust cyclone separator includes an air intake pipe 1, a guide body 3, a cylinder body 4, an exhaust pipe 5, an ash hopper 6, an ash discharge pipe 7 and an ash bin 8. The guide body 3 is located in the cylinder body 4, the exhaust pipe 5 is located below the guide body 3, the ash hopper 6 is arranged obliquely downward, the upper part is connected with the cylinder body 4, and the lower part is connected with the ash discharge pipe 7, the ash discharge hopper Pipe 7 lower part stretches in the ash bin 8.

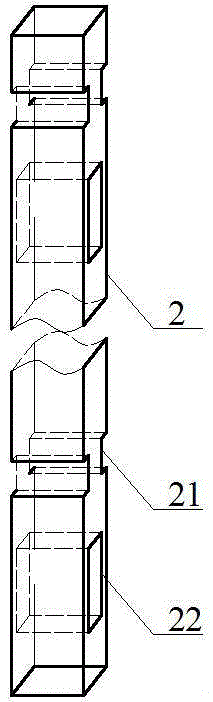

[0020] The feature of the present invention is that: several bypass columns 2 are installed in the air inlet pipe 1 . The surface of the circumventing column 2 is provided with several grooves 21 along the direction of air flow, and several through holes 22 are arranged in the middle along the direction of air flow, and several circumventing columns 2 are horizontally or vertically staggered in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com