Method And Device For The Thermal Treatment Of A Product

A heat treatment method and product technology, applied in food heat treatment, heat exchange equipment, lighting and heating equipment, etc., can solve the problems that positive pressure gradient cannot be observed, product quality is harmful, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

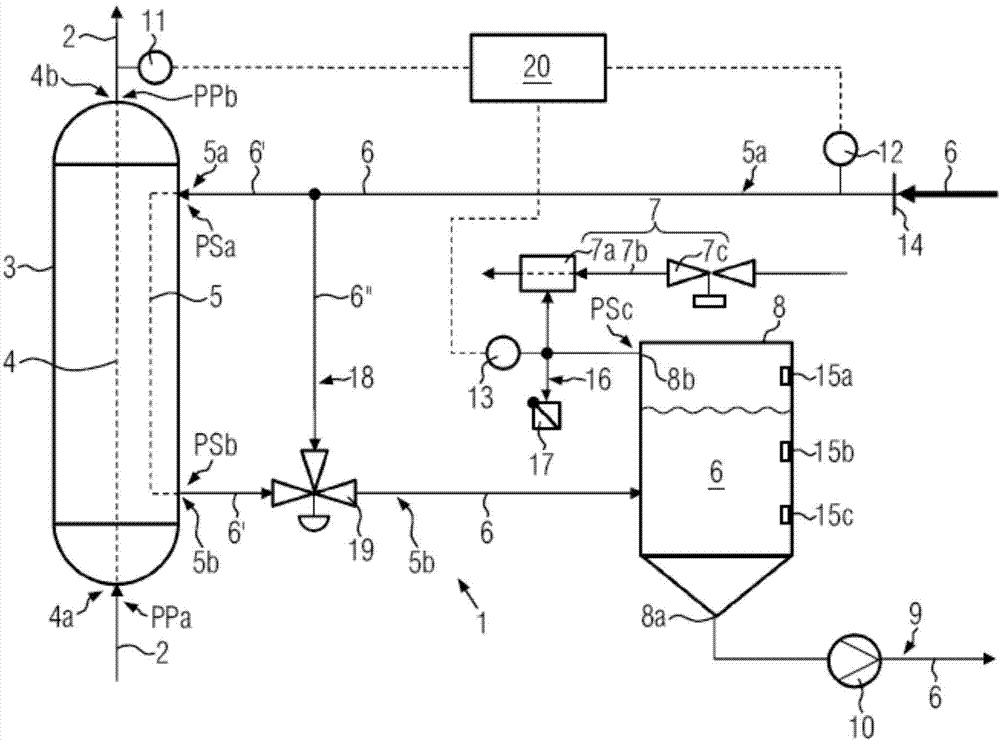

[0008] Preferably, the negative pressure is adjusted in response to a pressure difference measured between the outlet of the primary circuit and the feed pipe of the secondary circuit. In the remaining area of the heat exchanger, then at least this positive pressure gradient prevails between the primary and secondary circuits. The differential pressure can be monitored in a simple manner with conventional pressure gauges and control units.

[0009] Preferably, the returning exchange medium is collected in a vacuum tank. The exchange medium can then be temporarily stored under vacuum. The vacuum tank then acts as a system separation for the exchange medium conducted or collected under vacuum conditions from ambient pressure.

[0010] Preferably, the pressure of the vacuum tank is adjusted so that negative pressure prevails at the feed side of the secondary loop. Due to the return pipe of the secondary circuit, a positive pressure gradient from the primary circuit to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com