Method for reducing biogenic amine in fermented food

A technology for fermented food and biogenic amines, applied in the field of food processing, can solve the problems of high price of pure products and complicated extraction methods, and achieve the effect of improving safety and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

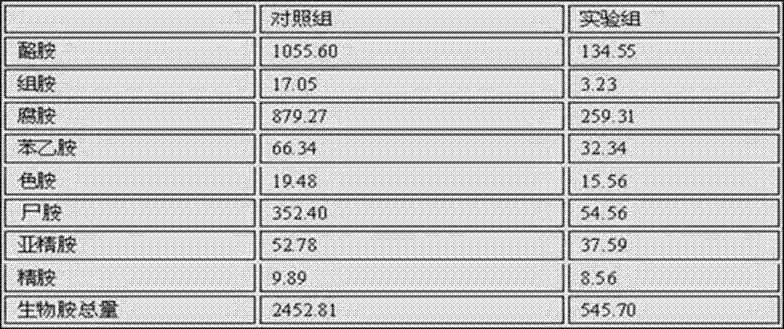

Embodiment 1

[0020] A method for reducing biogenic amines in soy sauce fermentation, the steps are as follows:

[0021] (1) Under sterile conditions, take an appropriate amount of Aspergillus niger spores, activate them with potato dextrose agar medium, and inoculate the activated Aspergillus niger strains in the modified Chase medium with sodium nitrate as the only nitrogen source, and cultivate The base composition is 0.2%NaNO 3 , 3% sucrose, 0.1%K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL. Temperature 28~30℃, speed 150r / min, culture for 48h;

[0022] (2) After the cultivation is completed, the bacteria are reinoculated in the modified Chapeauer's medium with n-butylamine as the only nitrogen source. The medium components are 0.2% n-butylamine, 3% sucrose, and 1.5% K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL. Then add 0.2μmol / L CuSO 4 ·5H 2 O for induction, the rotation speed was 150r / min, and cultured for 24h. ...

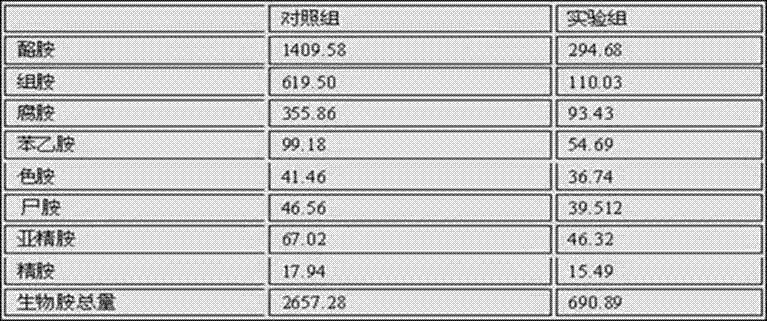

Embodiment 2

[0028] A method for reducing biogenic amines in fermented bean curd, the steps are as follows:

[0029] (1) Under aseptic conditions, take an appropriate amount of Aspergillus niger spores, activate them with potato dextrose agar medium, inoculate the Aspergillus niger strains obtained above in the improved Chapeauer medium with ammonium nitrate as the only nitrogen source, and cultivate The base composition is 0.2% ammonium nitrate, 3% sucrose, 0.1% K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL, distilled water. Temperature 28~30℃, speed 180r / min, culture for 24h;

[0030] (2) After the cultivation is completed, the bacteria are reinoculated in the modified Chapeauer's medium with n-butylamine as the only nitrogen source. The medium components are 0.2% n-butylamine, 3% sucrose, and 1.5% K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL. Then add 0.5μmol / L CuSO 4 ·5H 2 O for induction culture, rotating speed 18...

Embodiment 3

[0036] A method for reducing biogenic amines in food, the steps are as follows:

[0037] (1) Under aseptic conditions, take an appropriate amount of Aspergillus niger spores, activate them with potato dextrose agar medium, inoculate the Aspergillus niger strains obtained above in the modified Chapeauer medium with sodium nitrate as the only nitrogen source, and cultivate The base composition is 0.2%NaNO 3 , 3% sucrose, 0.1% K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL. The temperature is 28~30°C, the rotation speed is 200r / min, and cultured for 48h.

[0038] (2) After the cultivation is completed, the bacteria are reinoculated in the modified Chapeauer's medium with n-butylamine as the only nitrogen source. The medium components are 0.2% n-butylamine, 3% sucrose, and 1.5% K 2 HPO 4 , 0.05%MgSO 4 ·7H 2 O, 0.1% yeast extract, distilled water 1000mL. Then add 0.3μmol / L CuSO 4 ·5H 2 O for induction culture, rotating speed 200r / min, cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com