Preparation method for reproduced cheese preserved at normal temperature and product

A technology for processing cheese and room temperature, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of protein denaturation, cheese melting, low melting point of cheese, etc., and achieve the effect of crispy taste texture and good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

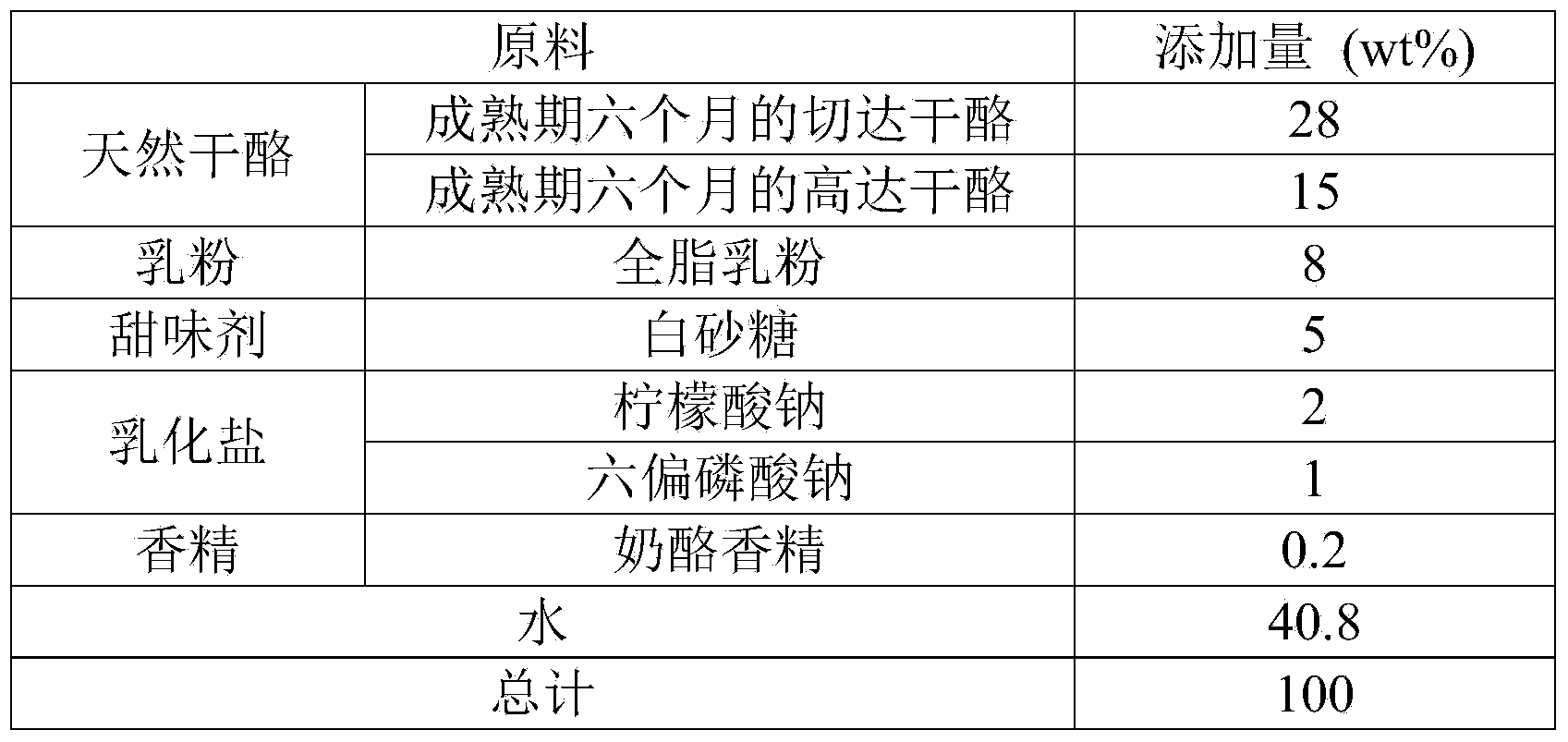

[0042] The raw material formula of the present embodiment is:

[0043] The raw material formula of the normal temperature preservation processed cheese of table 1 embodiment 1

[0044]

[0045] Preparation:

[0046] (1) Mixing sterilization and emulsification: heat natural cheese, milk powder, sweetener, emulsifying salt, essence and water to 65°C in a melting pot, and stir at 900rpm for 25min to make the material liquid mix evenly;

[0047] (2) Demoulding: The uniformly mixed material liquid is poured into a mold with a depth of 6mm while it is hot, and after cooling, it is placed in an environment of -18°C for preliminary pre-freezing for 6 hours, and then demoulded;

[0048] (3) Pre-freezing: place the unmoulded frozen cheese on a drying plate to distribute evenly, and place it in an environment of -35°C for 12 hours;

[0049] (4) Sublimation drying (primary drying): When the vacuum degree of the vacuum drying chamber reaches 60Pa, send the pre-frozen cheese together w...

Embodiment 2

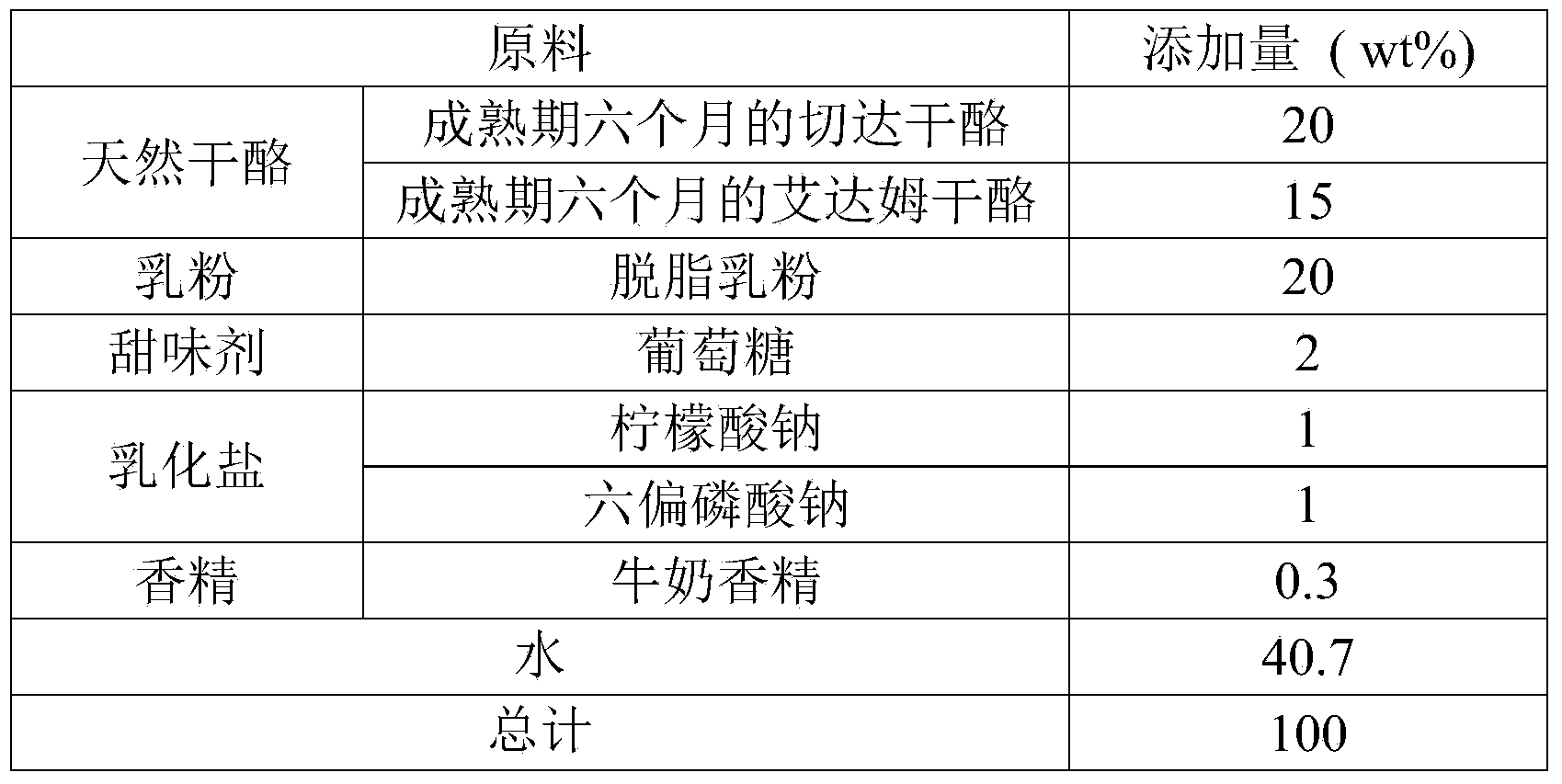

[0052] The raw material formula of the present embodiment is:

[0053] The raw material formula of the normal temperature preservation processed cheese of table 2 embodiment 2

[0054]

[0055] Preparation:

[0056] (1) Mixing sterilization and emulsification: heat natural cheese, milk powder, sweetener, emulsifying salt and water to 99°C in a melting pot, and stir for 5 minutes at a speed of 3000rpm to make the material liquid mix evenly;

[0057] (2) Demoulding: The uniformly mixed feed liquid is poured into a mold with a depth of 2 mm while it is hot, and after cooling, it is placed in an environment of -25°C for preliminary pre-freezing for 12 hours, and the mold is demoulded;

[0058] (3) Pre-freezing: place the unmoulded frozen cheese on a drying plate to distribute evenly, and place it in an environment of -60°C for 4 hours;

[0059] (4) Sublimation drying (primary drying): When the vacuum degree of the vacuum drying chamber reaches 20Pa, send the pre-frozen cheese...

Embodiment 3

[0062] The raw material formula of the present embodiment is:

[0063] The raw material formula of the normal temperature preservation processed cheese of table 3 embodiment 3

[0064]

[0065] Preparation:

[0066] (1) Mixing sterilization and emulsification: heat natural cheese, milk powder, sweetener, emulsifying salt, essence and water to 85°C in a melting pot, and stir at 600rpm for 15min to make the material liquid mix evenly;

[0067] (2) Demoulding: The uniformly mixed material liquid is poured into a mold with a depth of 6mm while it is hot, and after cooling, place it in an environment of -10°C for preliminary pre-freezing for 6 hours, and then demould;

[0068] (3) Pre-freezing: place the unmoulded frozen cheese on a drying plate to distribute evenly, and place it in an environment of -35°C for 12 hours;

[0069] (4) Sublimation drying (primary drying): When the vacuum degree of the vacuum drying chamber reaches 80Pa, send the pre-frozen cheese together with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com