Multilayer structure useful for electrical insulation

A multi-layer structure and additional layer technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as uneven adhesion of paper materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 and 2

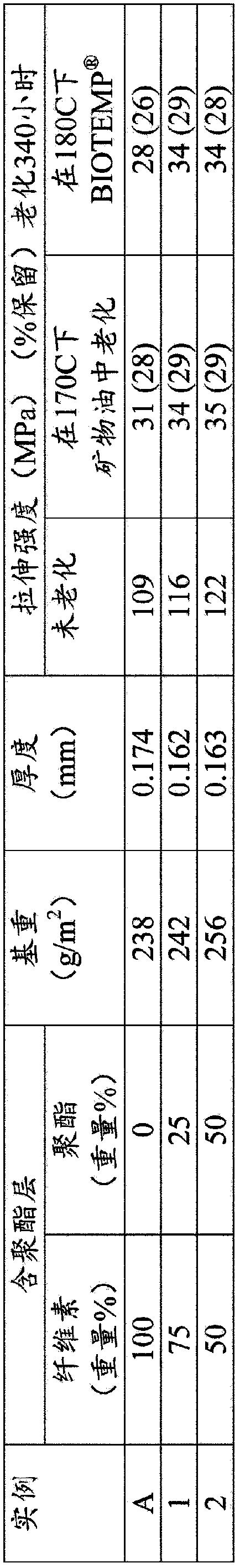

[0048] A two-layer structure according to the invention was prepared in a similar manner to Comparative Example A, except that one cellulose layer was replaced by a polyester / cellulose layer. The polyester / cellulose layer was prepared in a manner similar to that used to prepare the cellulose layer, except that a portion of the cellulose was replaced with 6 mm (1 / 4 inch) polyester floe. The polyester floc was spun from poly(cyclohexanedimethanol terephthalate) (PCT, available from Eastman Inc.) and poly(trimethylene terephthalate) ( PTT, made from melt-spun fibers of melt blends available from E.I. du Pont de Nemours and Co., Wilmington, Delaware). The final compositions are listed in Table 1. The properties of the resulting two-layer structures are listed in Table 1.

[0049] Table 1

[0050] Two-level structure and properties

[0051]

[0052] Table 1 shows that Examples 1 and 2 show a slight improvement in tensile strength retention.

example 3-5

[0058] The monolayer structure of the first layer of the multilayer structure according to the present invention was prepared in a similar manner to Comparative Example C, except that part of the cellulose was replaced with 6 mm (1 / 4 inch) polyester floe. The polyester floc was spun from poly(cyclohexanedimethanol terephthalate) (PCT, available from Eastman Inc.) and poly(trimethylene terephthalate) ( PTT, available from melt spun fibers of melt blends from E.I. du Pont de Nemours and Co., Wilmington, Delaware). The final compositions are listed in Table 2. The properties of the resulting monolayer structures are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com