Testing method of low-light performance of solar cell assembly

A technology of solar cells and testing methods, applied in the monitoring of photovoltaic systems, electrical components, photovoltaic power generation, etc., can solve the problems of expensive testing equipment, inability to obtain I-V data, and inability to guarantee spectral uniformity. Good low-light effect, simple test method, and real-time monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

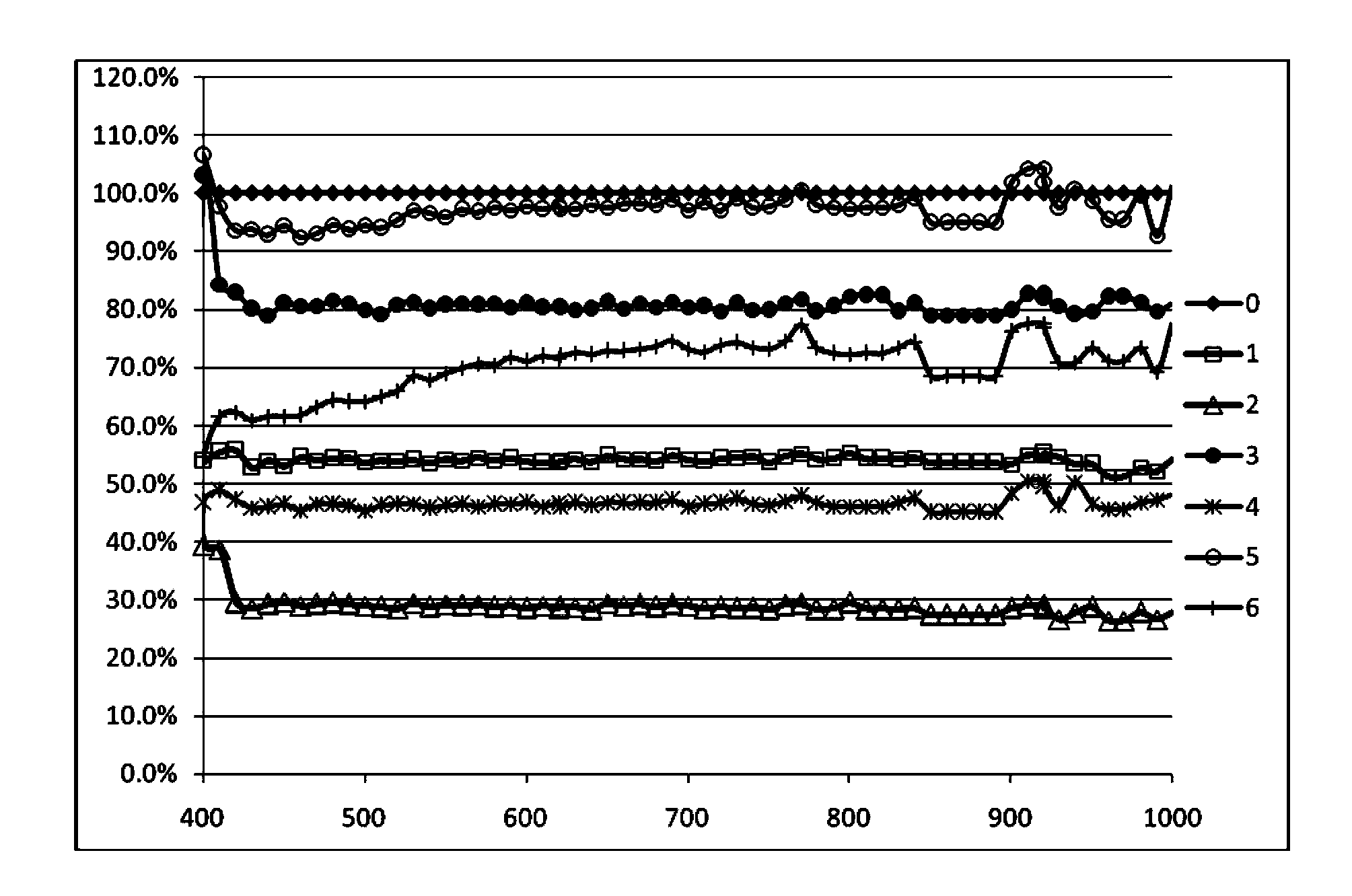

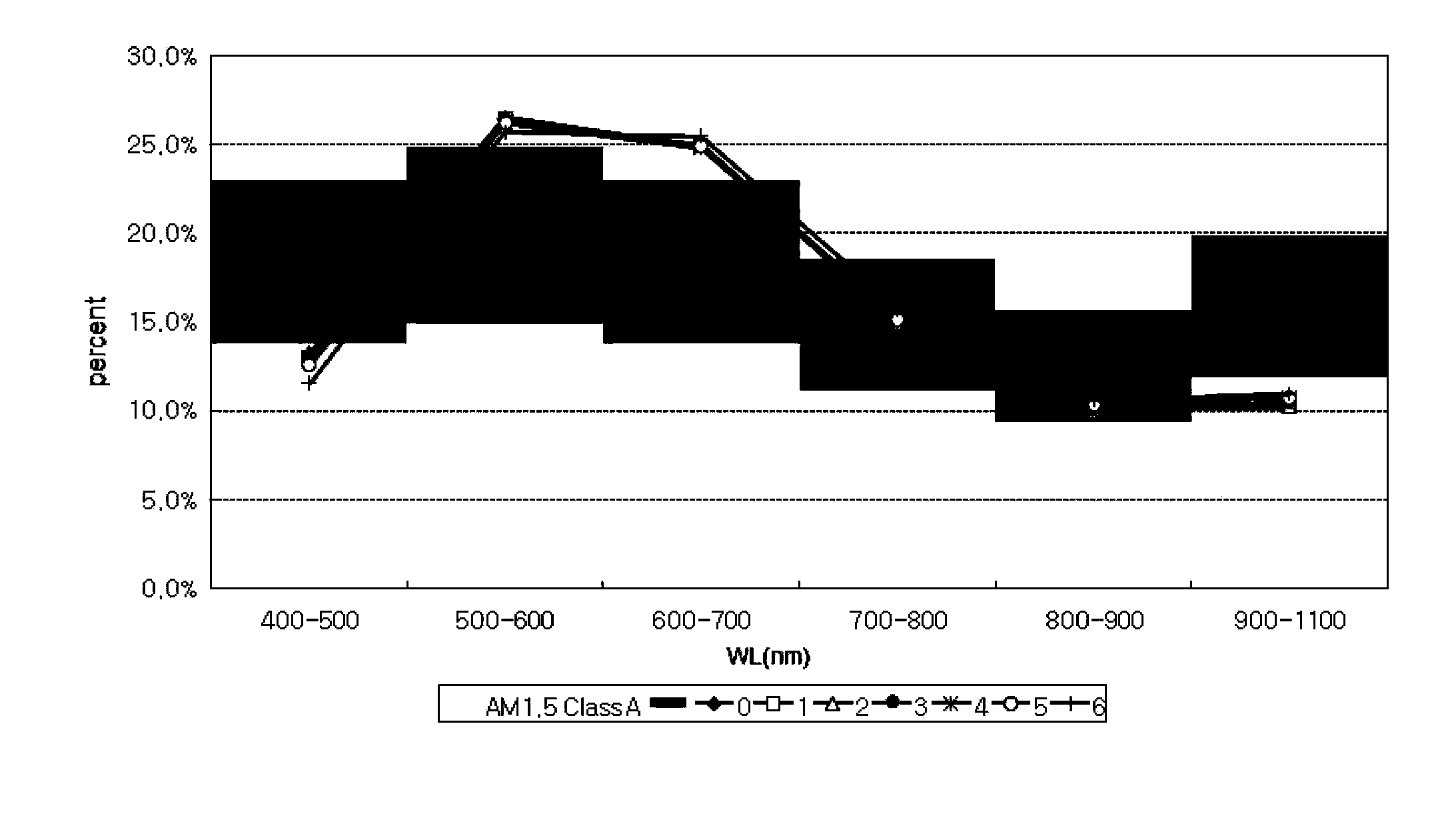

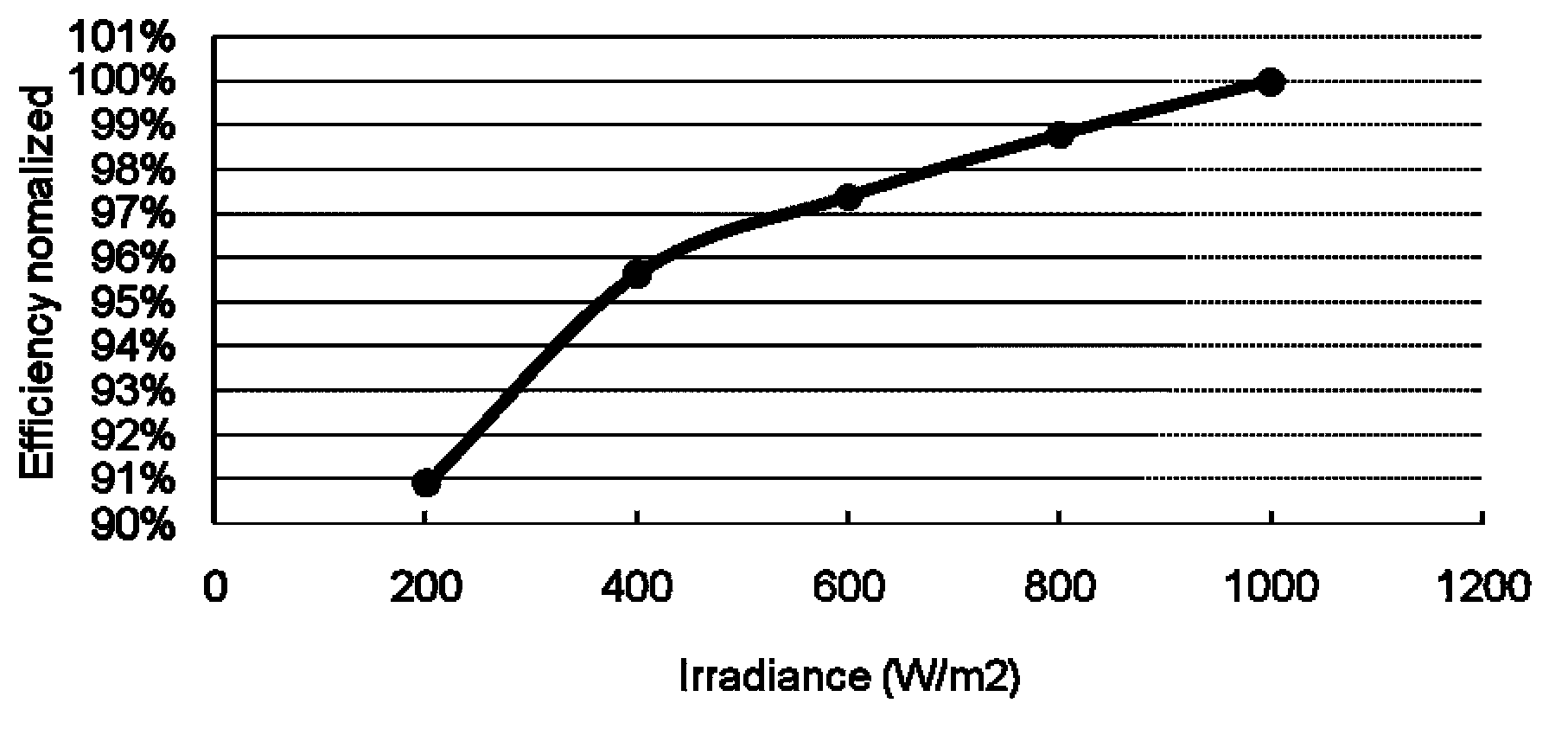

[0026] (1) Nisshinbo double light source horizontal solar simulator is used, with a test area of 1.43m 2 solar cell module, the light intensity is 1000W / m 2 The maximum output power is 125 watts;

[0027] (2) One-layer and two-layer stainless steel wire mesh are respectively used as filter devices on the surface of the uniform plate of the solar simulator, and the light intensity when the one-layer and two-layer stainless steel wire mesh are covered is measured by a spectroradiometer. 800W / m 2 and 406W / m 2 , through the I-V scanning system of the solar simulator, the maximum output power of the solar cell module is 98 watts and 47.5 watts when it is covered with one layer and two layers of stainless steel wire mesh;

[0028] (3) According to the formula η=P max / (S×1000W / m 2 ) × 100% to obtain the corresponding conversion efficiency of the solar cell module under the different conditions of the above steps (1) and (2): the light intensity is 1000W / m 2 8.75% when covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com