Optical detection method for polar axis type telescope polar axis shaking errors

An optical detection and telescope technology, which is used in optical instrument testing, machine/structural component testing, and measuring devices, etc., can solve problems such as complex calculation processes, achieve high measurement accuracy, avoid mathematical calculation processes, and simple principles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

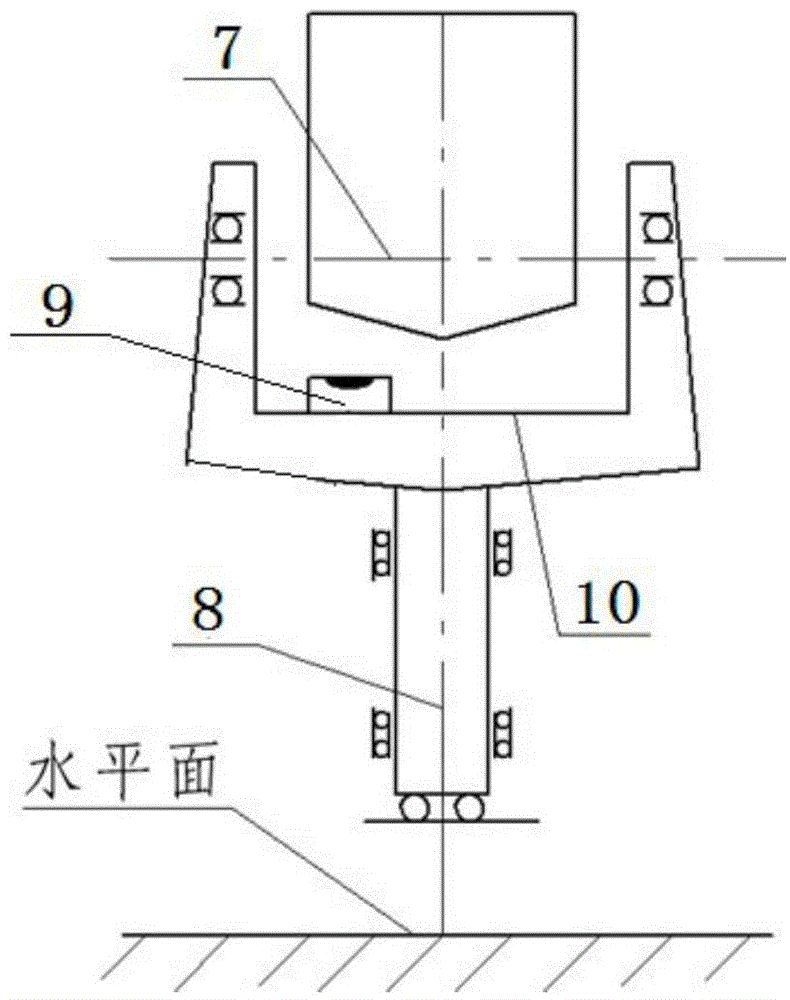

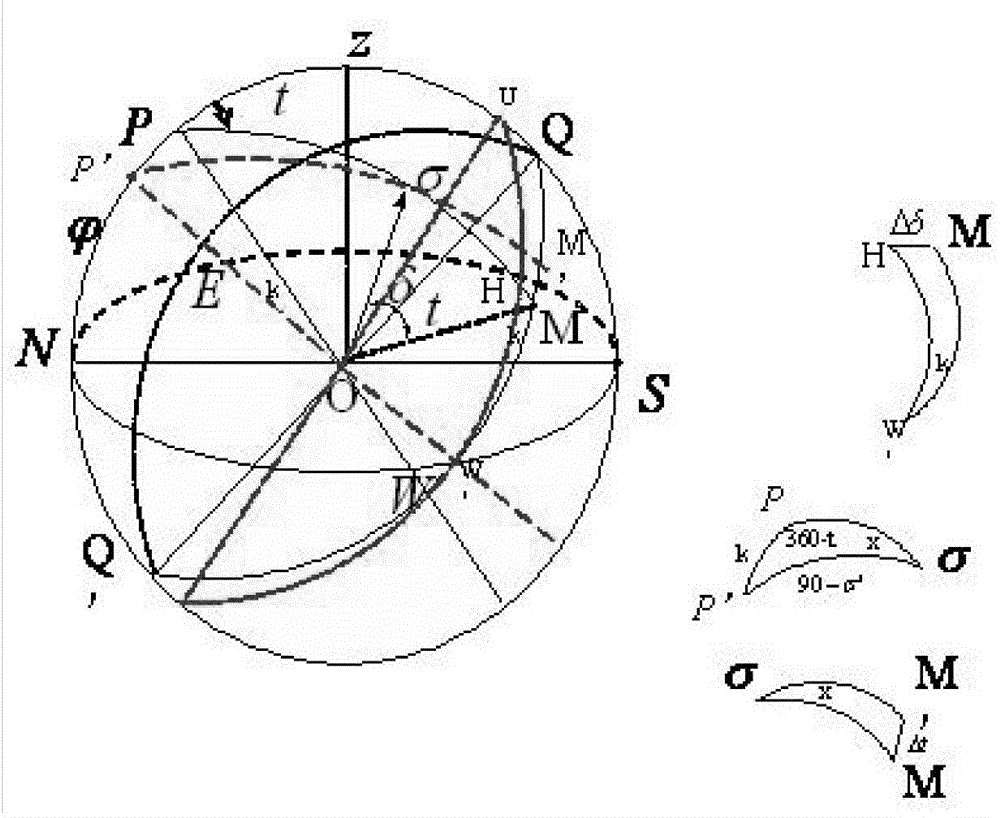

[0024] Such as figure 2 As shown, the optical detection method of the polar axis shake error of the polar axis type telescope of the present invention comprises the following steps:

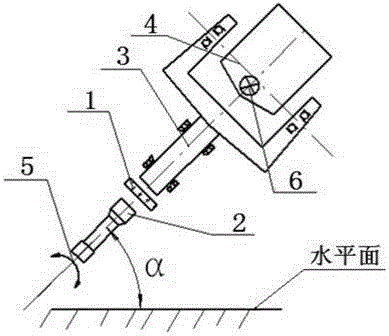

[0025] (1) Install a plane reflector 1 with two degrees of freedom adjustment mechanism on the shaft head of the polar axis 3 of the polar axis telescope, and use a 0.2" collimator 2 placed obliquely to align the plane reflector 1. The optical axis of the 0.2" collimator 2 is parallel to the axis of the polar axis 3.

[0026] (2) Rotate the polar axis 3 at intervals of 30°, and at the same time read the component data in the pitch direction 5 and the component data in the azimuth direction 6 on the 0.2" collimator 2, and rotate 360° continuously, measuring 12 in total point, the above process is repeated 4 times, and the data read on the 0.2"collimator 2 are recorded in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com