Inorganic phase change heat storage device capable of reducing phase separation

A technology of inorganic phase change and heat storage devices, which is applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., and can solve the problems that cannot be applied and popularized, and the service life of inorganic phase change heat storage materials is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

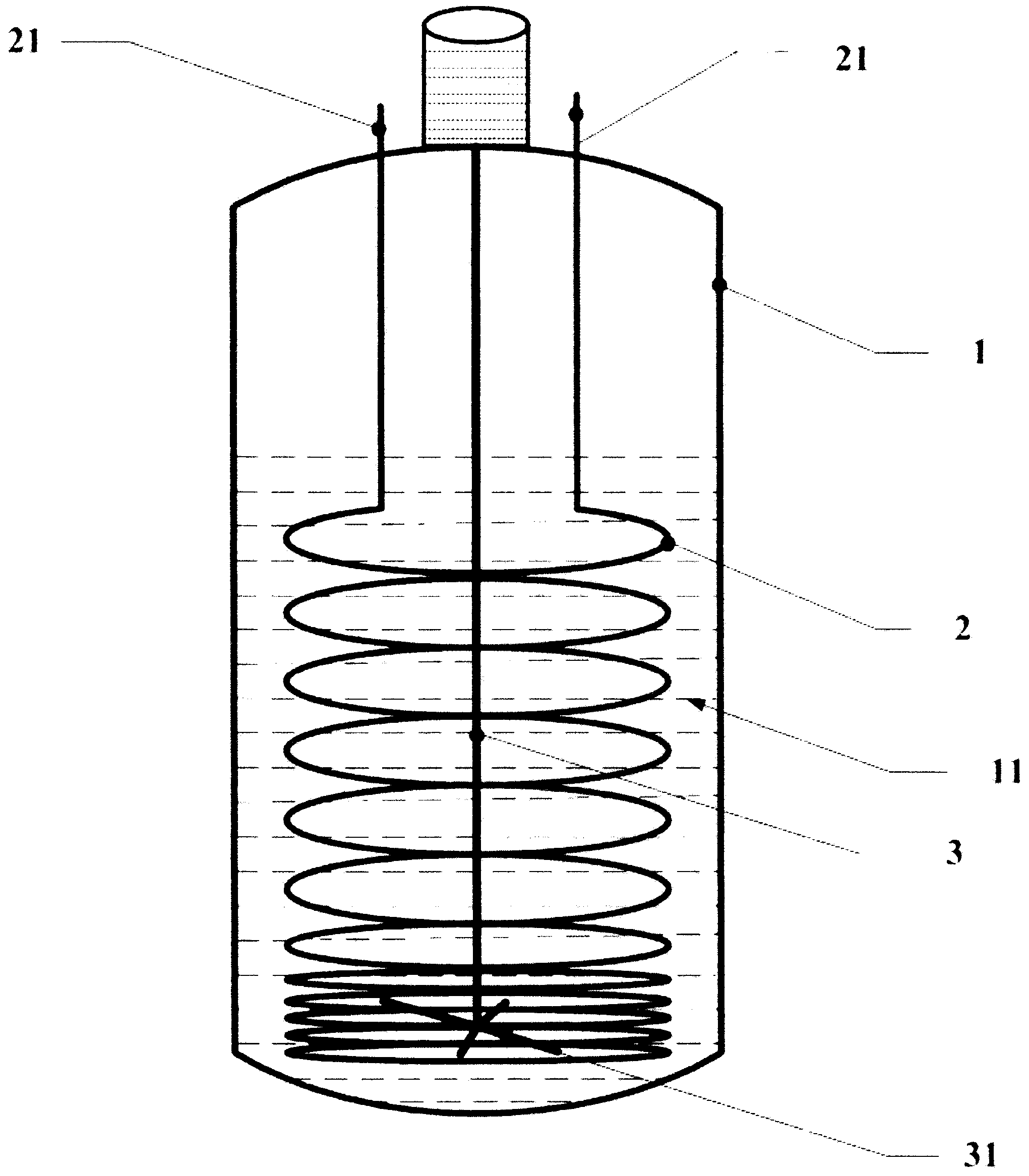

[0008] An inorganic phase-change thermal storage device that reduces phase separation. The container (1) has a diameter of 0.65 meters and a height of 1.5 meters. The inorganic phase-change thermal storage material (11) is sodium silicate nonahydrate, filling two-thirds of the cavity of the container ; The heat exchange tube (2) is a copper tube, and the heat exchange medium is water.

[0009] First start the heat storage process, 80 ° C hot water enters the heat exchange tube from the heat exchange tube port (21), and then flows out from the other port (21) for reheating, so that the heat storage material (11) in the container is heated by circulation, The flow rate of hot water is 0.25m / s. The density of the heat exchange tube near the blade of the agitator is high, and the solid-phase heat storage material (11) around it starts to melt first, and the agitator starts to stir as the melting proceeds, and the speed is slowly increased to 100r / min. After one hour, all the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com