Ultrafine grinder liquid nitrogen cooling device

A superfine pulverizer and liquid nitrogen cooling technology, which is applied in household refrigeration devices, lighting and heating equipment, grain processing, etc., can solve the problems of limiting the application range of superfine pulverizers, reducing the nutritional content of food and the efficacy of medicines, etc. , to achieve high commercial practical value, reduce temperature, and improve the effect of crushing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

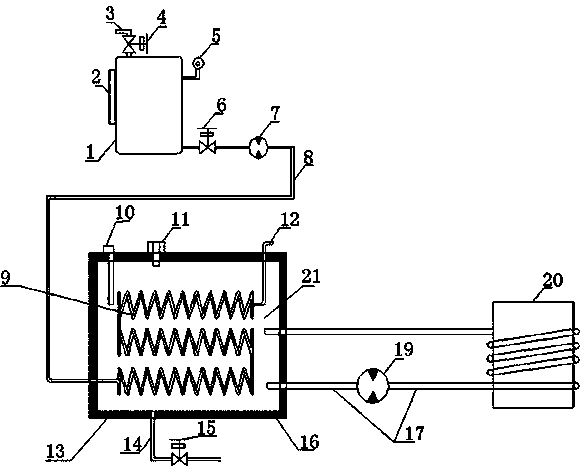

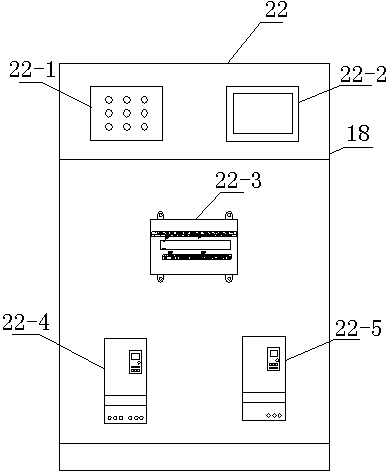

[0018] The ultrafine pulverizer liquid nitrogen cooling device of this embodiment mainly includes a liquid nitrogen tank 1, a liquid nitrogen pump 7, a vacuum insulation pipeline 8, a water bath vaporizer 9, a stainless steel coolant tank 13, a coolant pump 19, and a coolant 21 , Electric control system 22.

[0019] When working, first check whether the liquid nitrogen tank level gauge 2 and the liquid nitrogen tank pressure gauge 5 are normal, and the manual valve 4 of the liquid nitrogen injection port and the manual valve 15 of the sewage discharge port should be in the closed state. First open the manual valve 6 of the liquid nitrogen tank, turn on the power and press the electric control button 22-1 to start the system, the liquid nitrogen pump 7 starts to run, and the liquid nitrogen flows from the liquid nitrogen tank 1 through the vacuum insulation pipeline 8 into the water bath vaporizer 9 In the water-bath evaporator 9, the nitrogen vaporizes and absorbs heat, change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com