V-N microalloyed high-toughness large-specification steel angle and production method thereof

A technology of micro-alloying and large-scale toughness, which is applied in the field of hot-rolled section steel and can solve problems such as easy fracture of angle steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

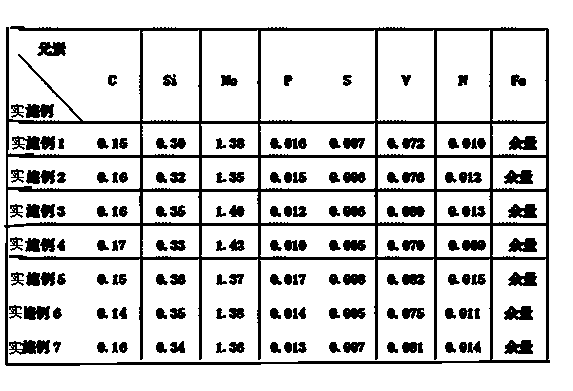

Examples

Embodiment 1

[0032] In Example 1, the process parameters of the rolling process are controlled as follows: the rectangular billet obtained by continuous casting is heated to 1265 ° C in a heating furnace and then subjected to rough rolling and finish rolling. The starting temperature of the rough rolling mill is controlled at 1050 ° C. The final rolling temperature is 820°C, and the single-pass reduction rate is greater than 20%. After rolling, atomization cooling is used to cool the angle steel uniformly and rapidly at a cooling rate of 28°C / s to 680°C, and then at a cooling rate of 0.05°C / s s cooling rate to 450 ° C, and then air cooled to room temperature. Produced according to the above process parameters, the final product structure is ultrafine ferrite + granular or short rod pearlite structure, the ferrite grain size is 3.4μm; and fine carbon and nitrogen are dispersed on the ferrite matrix Vanadium oxide or vanadium nitride particles with an average particle size of 9nm.

Embodiment 2

[0033] In Example 2, the process parameters of the rolling process are controlled as follows: the rectangular billet obtained by continuous casting is heated to 1275 ° C in a heating furnace and then subjected to rough rolling and finish rolling. The starting temperature of the rough rolling mill is controlled at 1060 ° C. The final rolling temperature is 850°C, and the single-pass reduction rate is greater than 20%. After rolling, atomization cooling is used to cool the angle steel uniformly and rapidly at a cooling rate of 26°C / s to 720°C, and then at a cooling rate of 2°C / s s cooling rate to 450 ° C, and then air cooled to room temperature. Produced according to the above process parameters, the final product structure is ultrafine ferrite + granular or short rod pearlite structure, the ferrite grain size is 3μm; and fine carbonitride is dispersed on the ferrite matrix Vanadium or vanadium nitride particles with an average particle size of 2 nm.

Embodiment 3

[0034] In Example 3, the process parameters of the rolling process are controlled as follows: the rectangular billet obtained by continuous casting is heated to 1269 ° C in a heating furnace and then subjected to rough rolling and finish rolling. The starting temperature of the rough rolling mill is controlled at 1057 ° C. The final rolling temperature is 828°C, and the single-pass reduction rate is greater than 20%. After rolling, atomization cooling is used to cool the angle steel uniformly and rapidly at a cooling rate of 32°C / s to 687°C, and then at a cooling rate of 1°C / s s cooling rate to 450 ° C, and then air cooled to room temperature. Produced according to the above process parameters, the final product structure is ultrafine ferrite + granular or short rod pearlite structure, the ferrite grain size is 3.1μm; and fine carbon and nitrogen are dispersed on the ferrite matrix Vanadium oxide or vanadium nitride particles with an average particle size of 3.6nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com