Method for producing 2,5-dimethyl-2,5-hexanediol by employing alkynylation condensation process

A technology of dimethyl and hexanediol, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, alkali metal compounds, etc., can solve problems that affect the economic benefits and sustainable development of enterprises, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

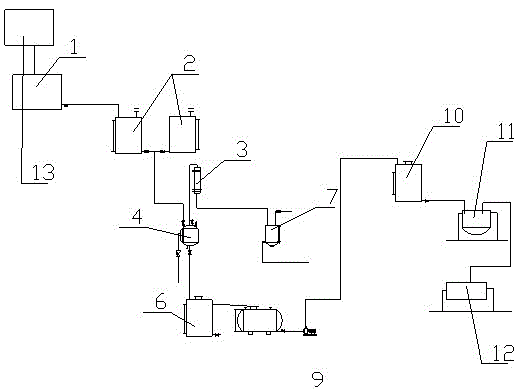

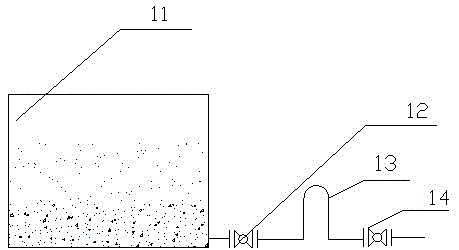

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as figure 1 The shown alkynylation condensation method produces 2,5-dimethyl-2, the method for 5-hexanediol, and this method comprises the following steps: 1. reaction generates intermediate product hexynediol step; Drop into benzene in reactor 13 , Potassium hydroxide, stir, then pass nitrogen for 60 minutes, add acetylene, control the pressure of the reactor at 0.08MPa, slowly and evenly add acetone when the temperature of the reactor rises to 45°C, control the reaction temperature at 43-47°C, stop adding acetone After holding the pressure for 2 hours, then add water to wash;

[0022] 2. After washing, put the material into the potassium hydroxide separation kettle 1 for hydraulic pressure, and let it stand for stratification. After the stratification, the mixed solution of potassium hydroxide containing high concentration is put into the lye storage tank 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com