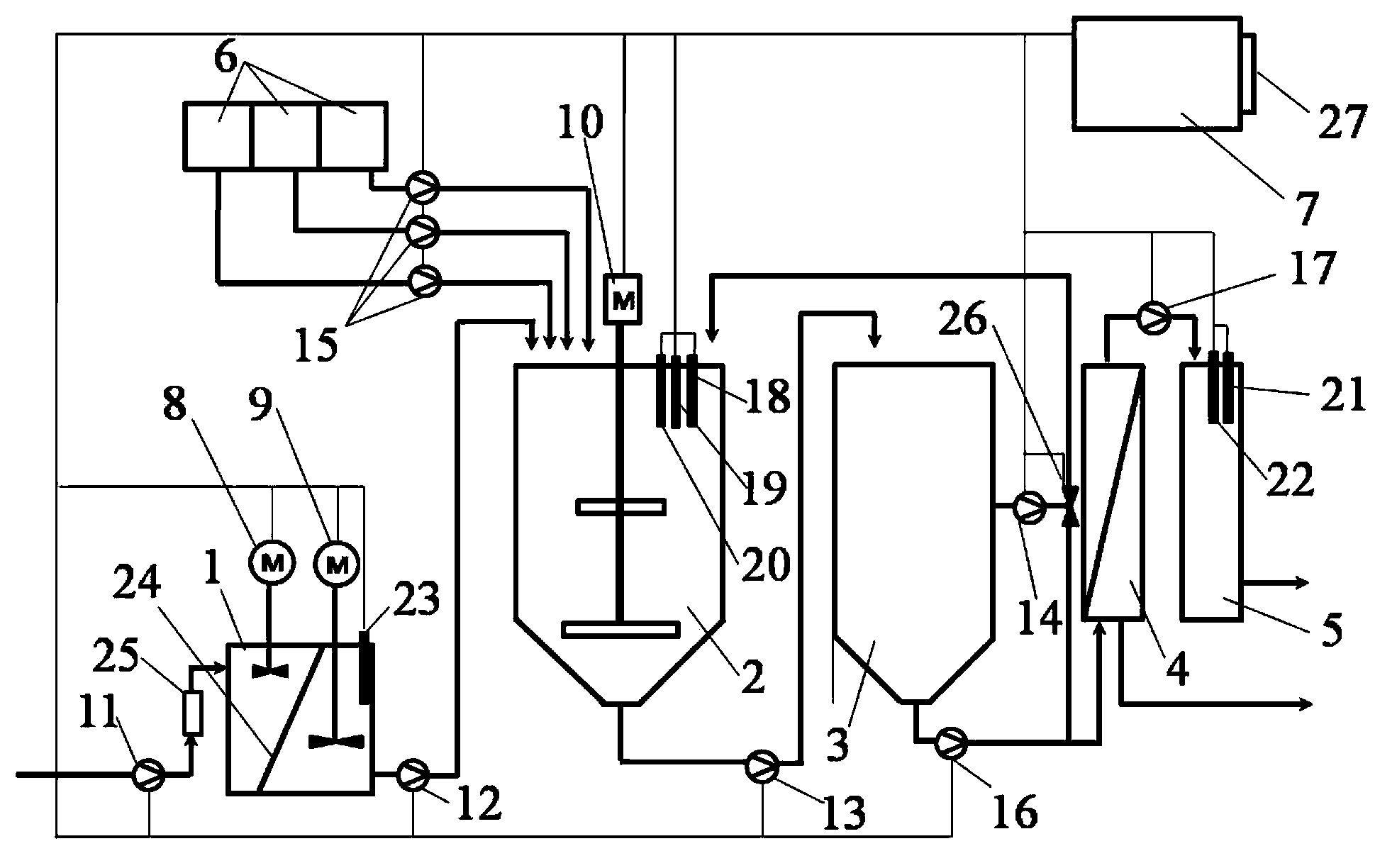

Method and device for modular programmed treatment of heavy metal waste liquid

A treatment device and heavy metal technology, applied in the field of water treatment, can solve the problems of long treatment process, substandard effluent quality, and large equipment footprint, achieving good treatment effect, easy promotion and implementation, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Heavy metal waste liquid from a hazardous waste disposal center, in which the hazardous waste is HW21 chromium-containing wastewater with a high concentration of heavy metal ions. After being processed by the heavy metal waste liquid modularized program-controlled equipment of the present invention, acid liquid, reducing agent, oxidizing agent, lye, oxidizing agent, reducing agent, flocculant, etc. are respectively stored in the dosing storage tank, and the batch processing volume is 1m 3 , and the treatment effect is shown in Table 1.

[0081] Table 1 Treatment effect of heavy metal waste liquid

[0082] project

[0083] total copper

Embodiment 2

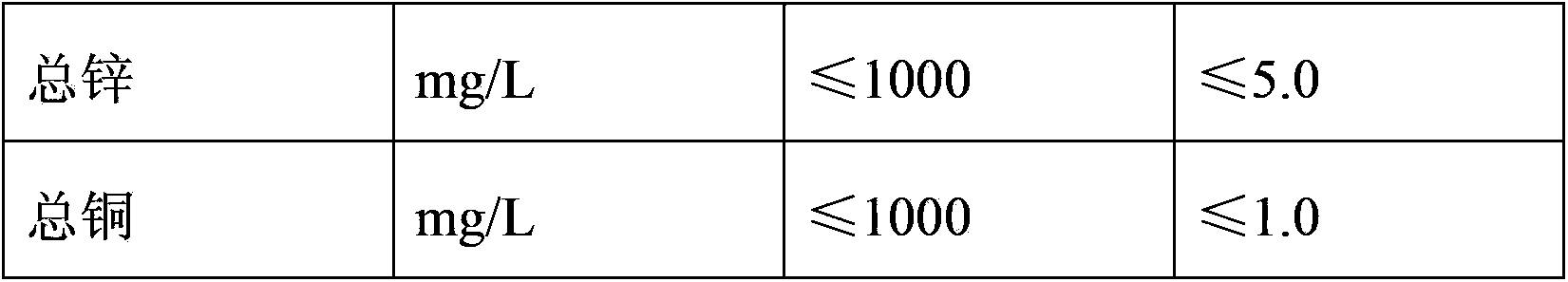

[0085] The heavy metal waste liquid in a hazardous waste disposal center, in which the hazardous waste is HW34 waste acid liquid, which contains a high concentration of heavy metal ions. After being processed by the heavy metal waste liquid modularized program-controlled equipment of the present invention, acid liquid, lye, oxidizing agent, reducing agent, oxidizing agent, reducing agent, and flocculant are respectively stored in the dosing storage tank, and the batch processing volume is 5m 3 , and the treatment effect is shown in Table 2.

[0086] Table 2 Treatment effect of heavy metal waste liquid

[0087]

[0088]

Embodiment 3

[0090] The heavy metal waste liquid in a hazardous waste disposal center, in which the hazardous waste is HW17 surface treatment waste with a high concentration of heavy metal ions. After being processed by the heavy metal waste liquid modularized program-controlled equipment of the present invention, the batch processing volume is 12m 3 , and the treatment effect is shown in Table 3.

[0091] Table 3 Treatment effect of heavy metal waste liquid

[0092] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com