Bi-directional spiral material-discharging bin

A two-way spiral, discharge bin technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of high maintenance and operation cost, complex structure, large discharge impact, etc., to achieve low maintenance and operation cost, blanking The effect of uniform distribution and small discharge impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

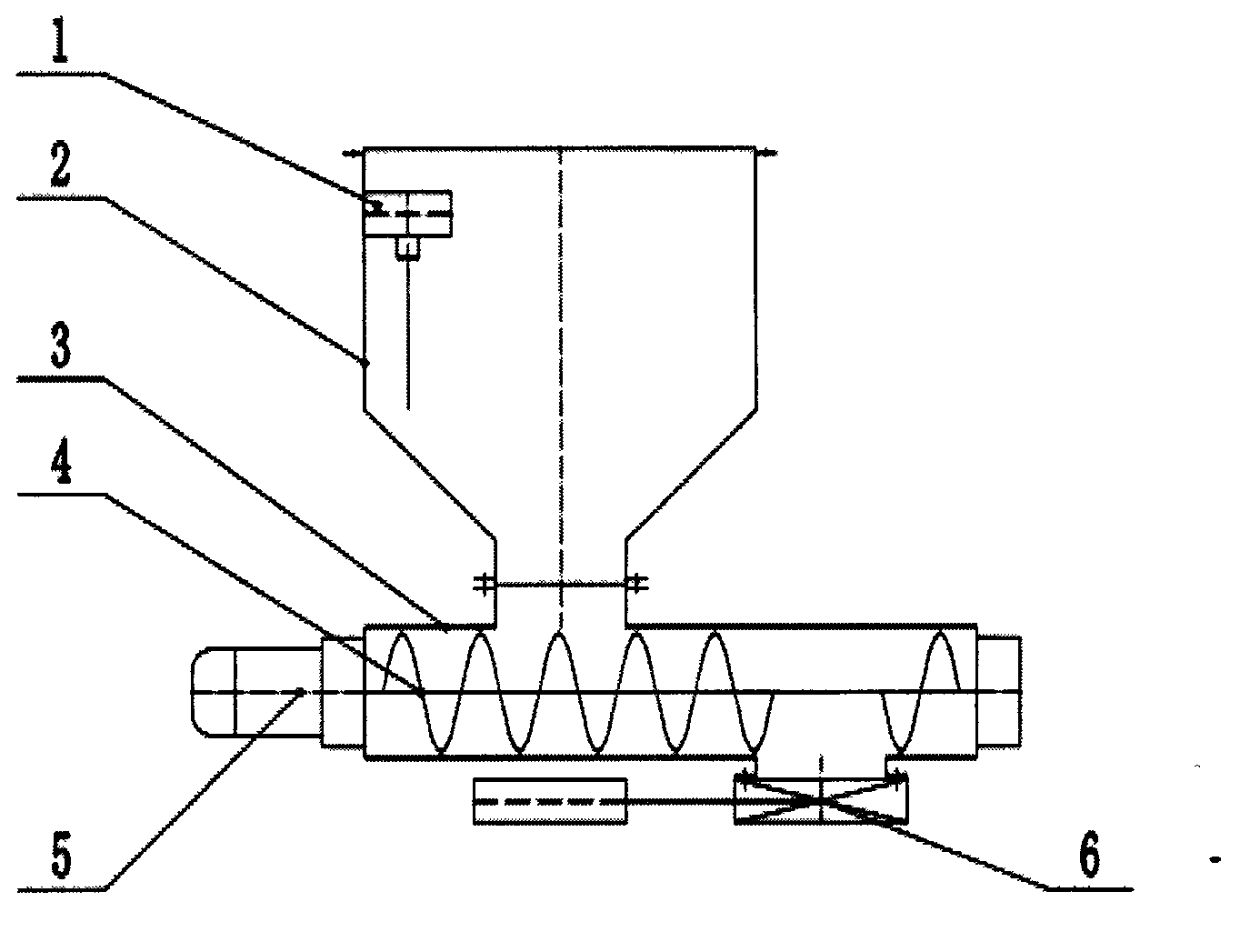

[0015] exist figure 1 Among them, the present invention includes a level meter 1, a discharge bin body 2, a push bin 3, a motor transmission device 4, a two-way screw 5 and a discharge valve 6, wherein the upper part of the discharge bin body 2 is cylindrical and the bottom is conical shape, and there is a material outlet at the bottom of the cone, the pusher bin 3 is cylindrical, with an upper feed port and a lower discharge port, the two-way screw 5 pusher bin 3 is a forward spiral, the pusher bin 3. The tail end is a reverse spiral. The level meter 1 for measuring the height of the accumulated material in the discharge bin body 2 is fixedly installed inside the discharge bin body 2. The outlet flange of the bottom material is sealed and connected by bolts, and the discharge valve 6 is sealed and connected with the flange of the lower discharge port of the push bin 3 by bolts.

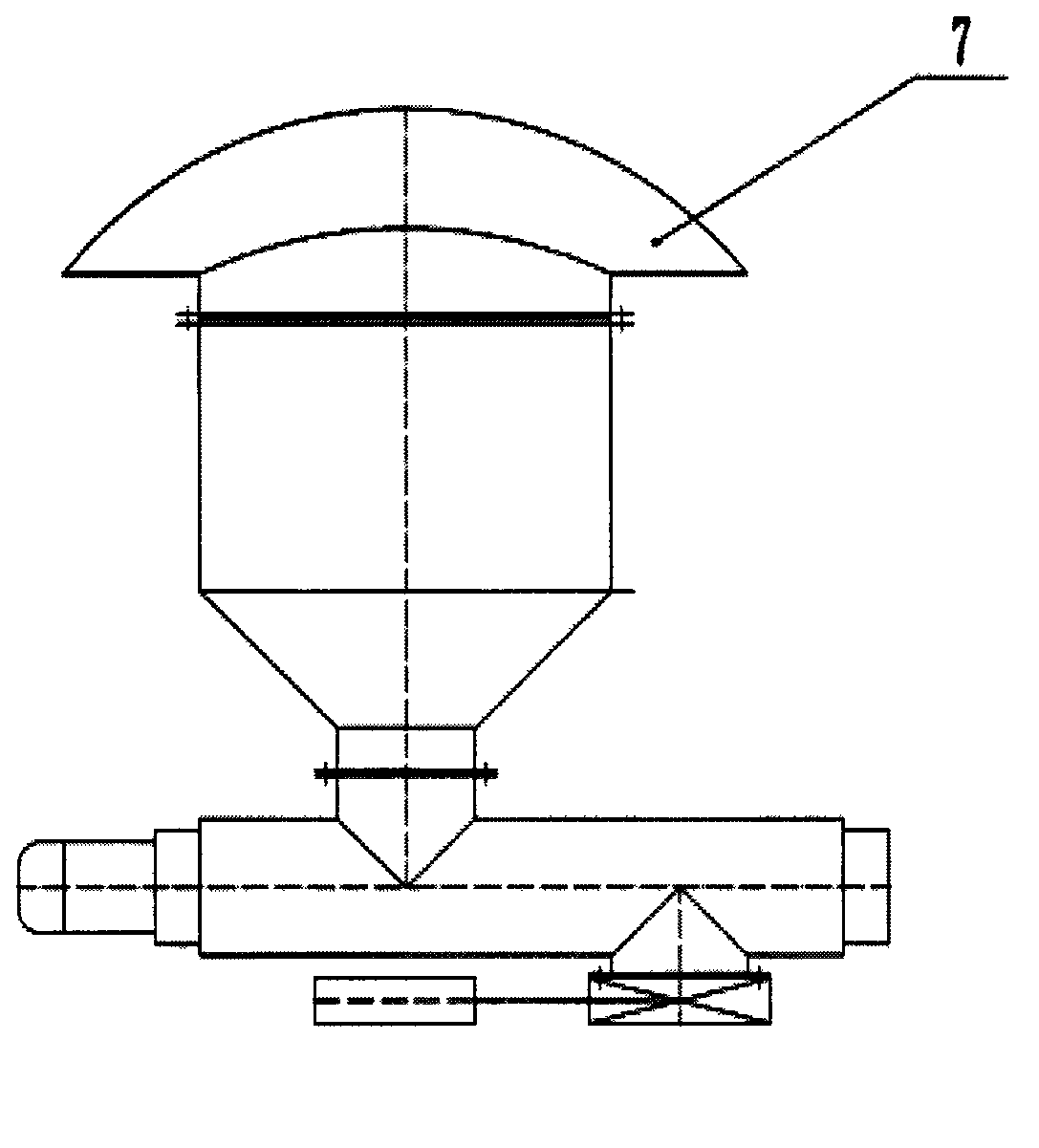

[0016] exist figure 2 Among them, the upper flange of the discharge bin body 2 is sealed and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com