Novel high safety lateral type cantilever stacking belt conveyor

A high-safety, belt conveyor technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of increasing maintenance time and cost, unable to guarantee smooth operation, and unable to guarantee absolute level, etc., to ensure normal operation. And the effect of personnel safety, simple structure, timely and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

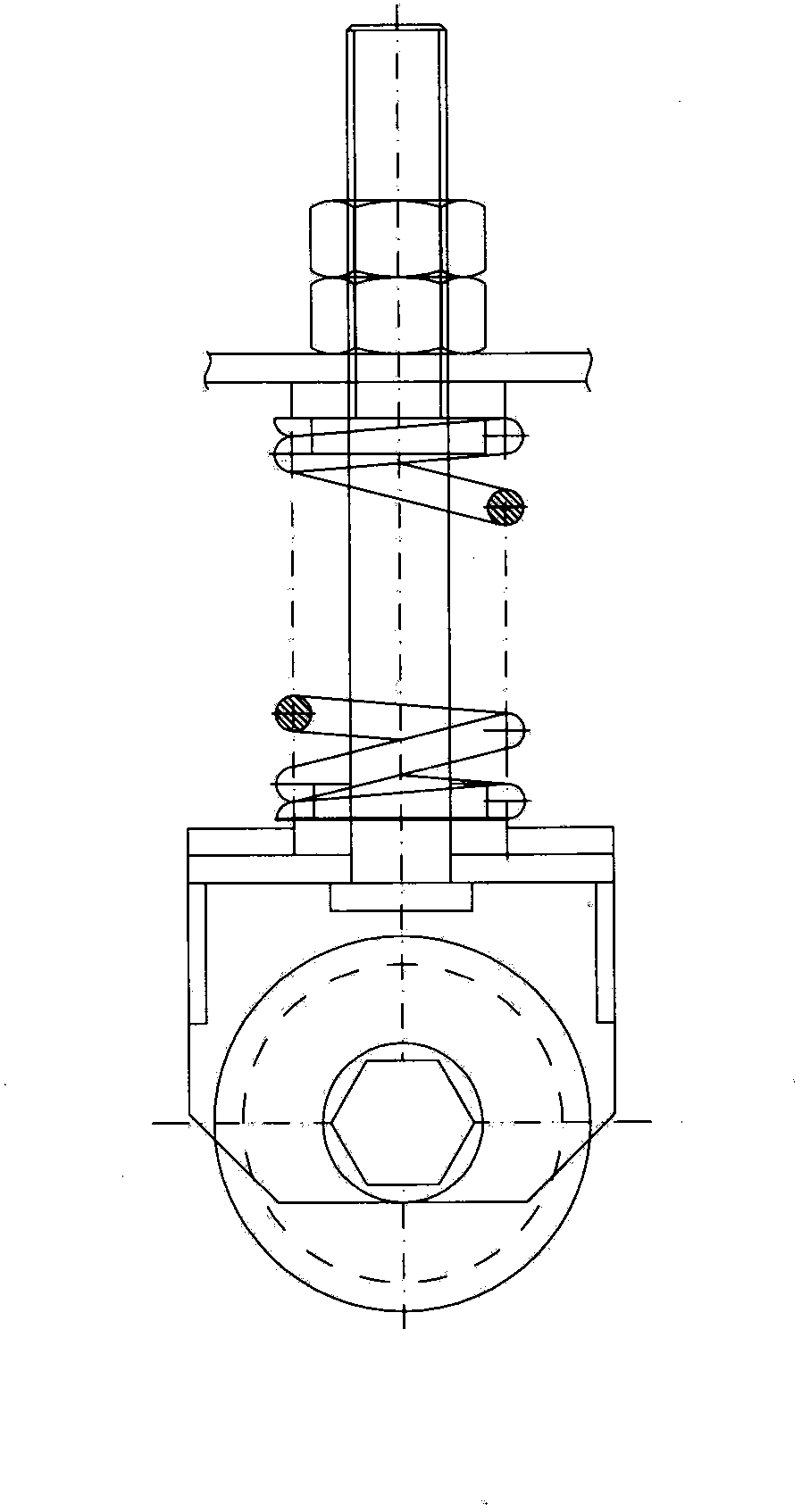

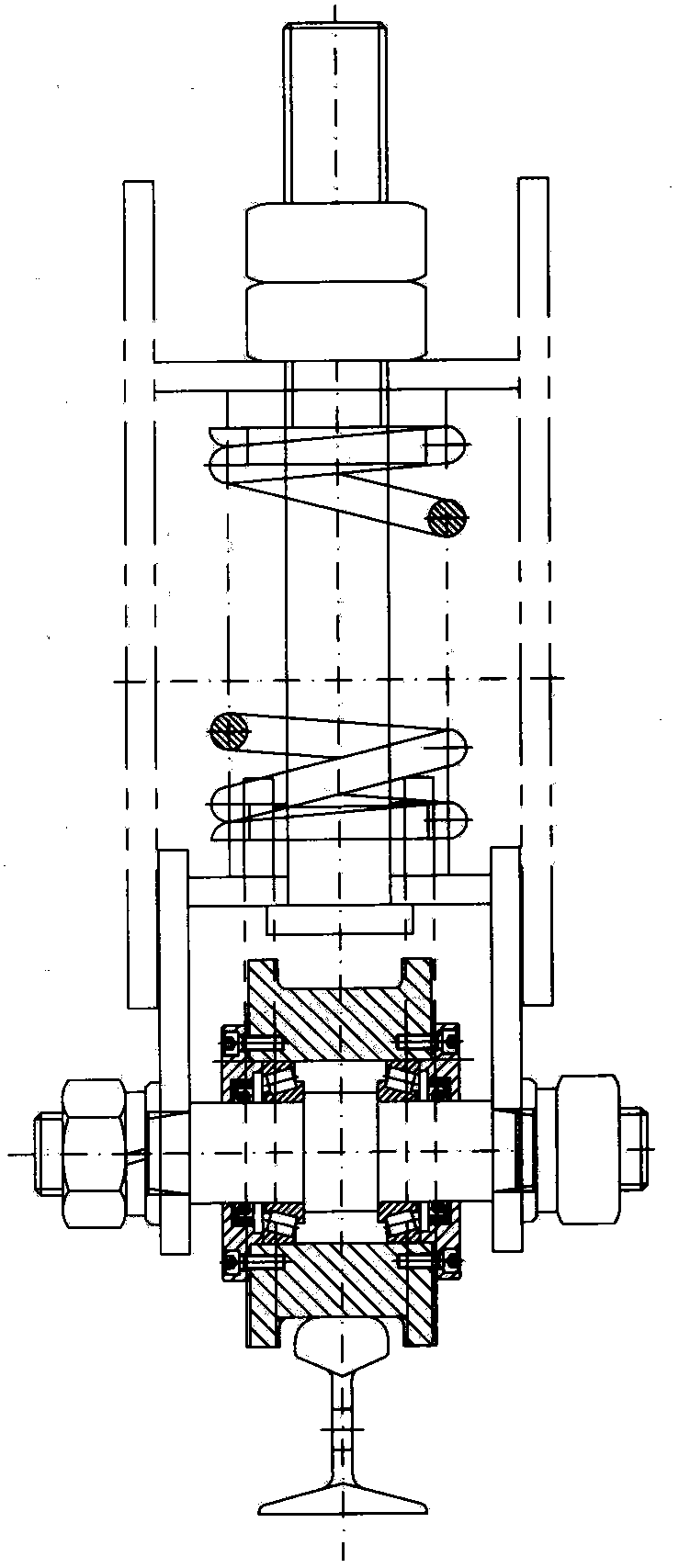

[0021] refer to Figure 1-Figure 5 , the specific embodiment adopts the following technical solutions: it includes a cantilever belt conveyor 1, a tripod hoisting device 2, an unloading car frame 3, a chute 4, an electric three-way funnel 5, a reduction motor 6, a row wheel group 7, a trolley Drive base 8, weight 9, trolley track 11, it also includes elastic wheel assembly 10, anti-rollover roller 12 and safety link assembly 13, cantilever belt conveyor 1 is arranged on the front part of unloading car frame 3, one end of which Hinged on the unloading truck frame 3, the other end is connected to the upper end of the unloading truck frame 3 through the tripod hoisting device 2 and the safety link assembly 13, and the unloading truck frame 3 is provided with an electric three-way funnel 5. A chute 4 is arranged on the lower end side of the electric three-way funnel 5, and the exit of the chute 4 is matched with the cantilever belt conveyor 1; On the two parallel tracks on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com