Making method of composite material tube

A manufacturing method and technology of composite materials, which are applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of high melting point or gasification temperature of foamed materials, cracking of pipe structures, and inability to produce, etc., to achieve dense structure, good quality Precision, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

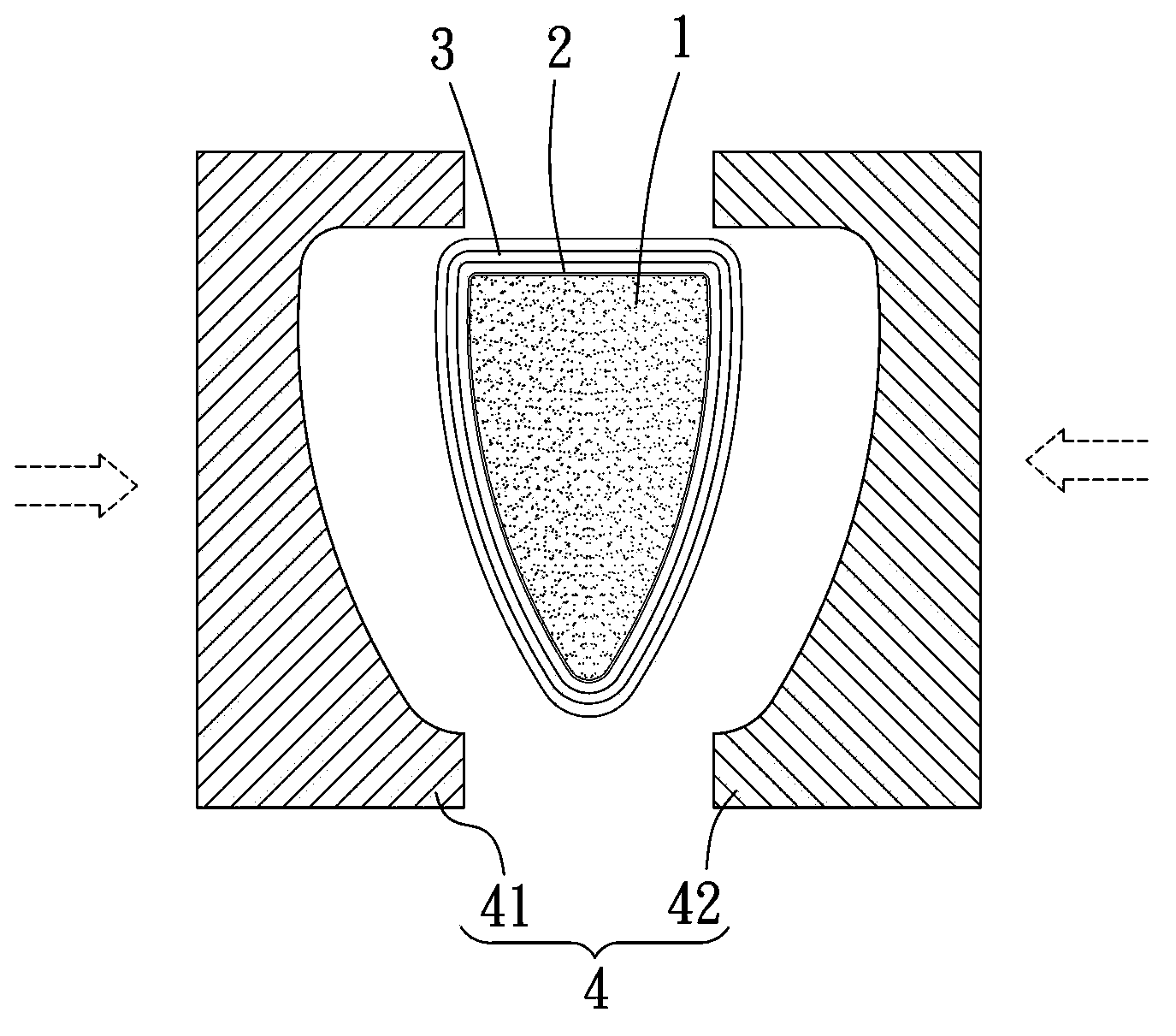

[0029] Please refer to Figure 1 to Figure 10 , the manufacturing method of the composite material pipe fitting of the present invention comprises the following steps:

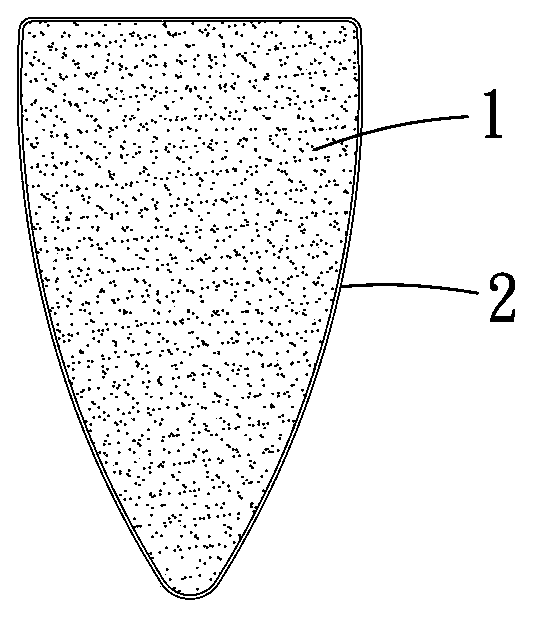

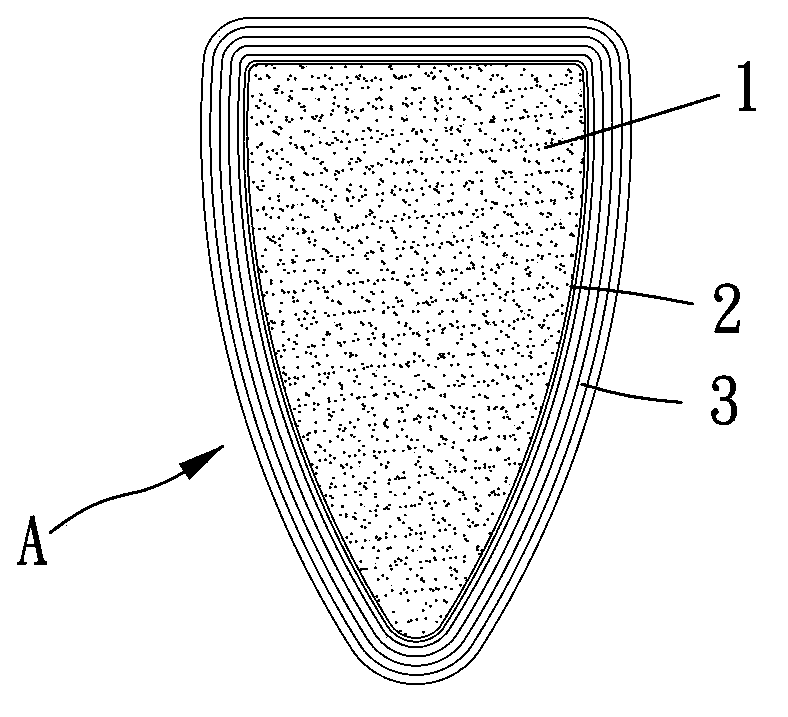

[0030] Preparation of the mandrel: the mandrel 1 is solid and made of a material containing a foamable substance or a substance with a large expansion coefficient and a soluble substance. When the mandrel 1 is heated to a predetermined temperature, its volume increases, preferably , the substance with a large expansion coefficient is silica gel, the foamable substance can be a foamable plastic and the predetermined temperature is the foaming temperature of the foamable plastic, the soluble substance is a water-soluble substance, especially a water-soluble In the main embodiment of the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com