Shaping device for paraffin pipe

A paraffin and cavity technology, which is applied in the field of paraffin processing equipment and paraffin tube shaping equipment, can solve the problems of unstable equipment, waste of energy, and uneven surface of the tube body, so as to save energy, improve production efficiency, and reduce remelting The effect of the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

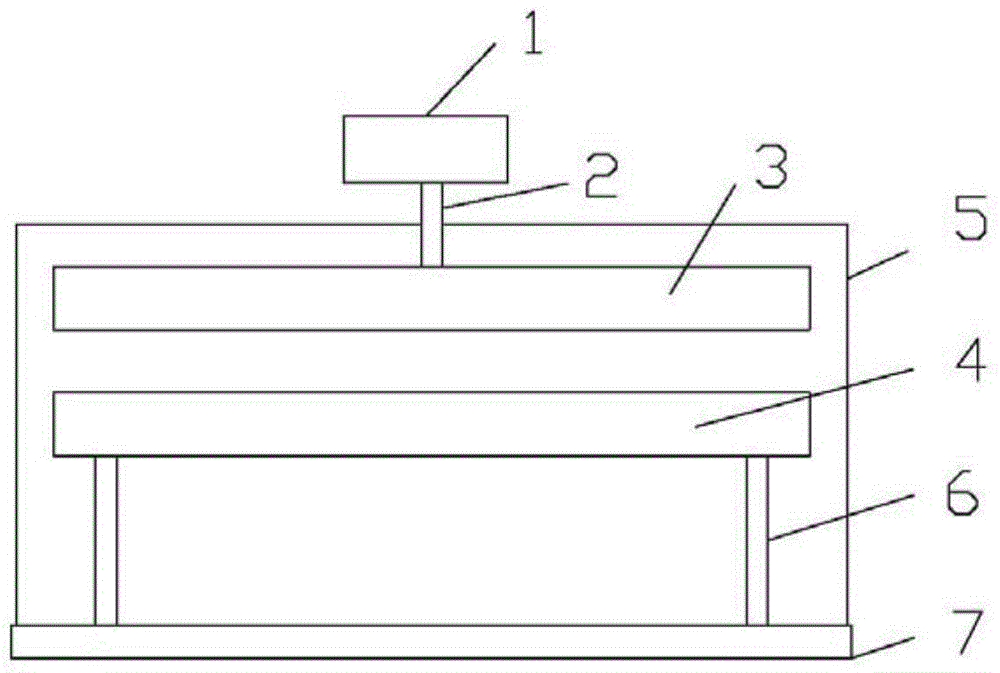

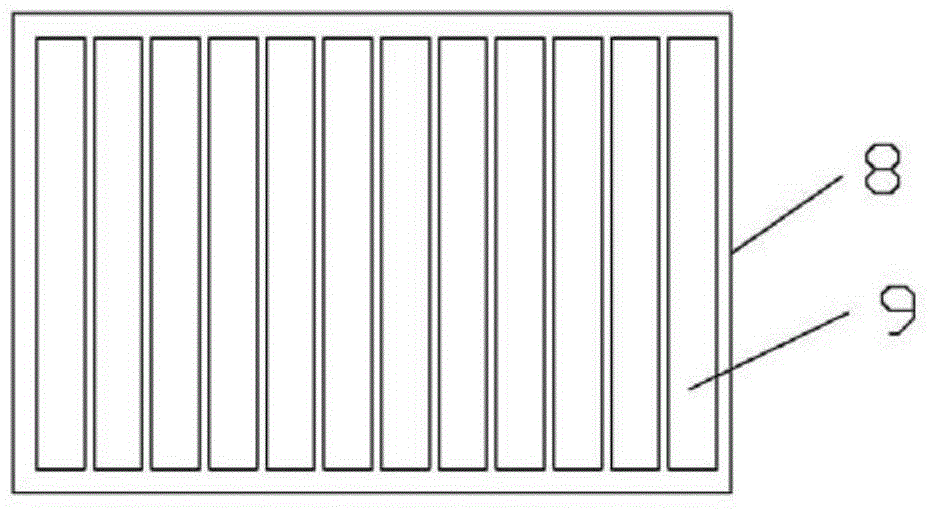

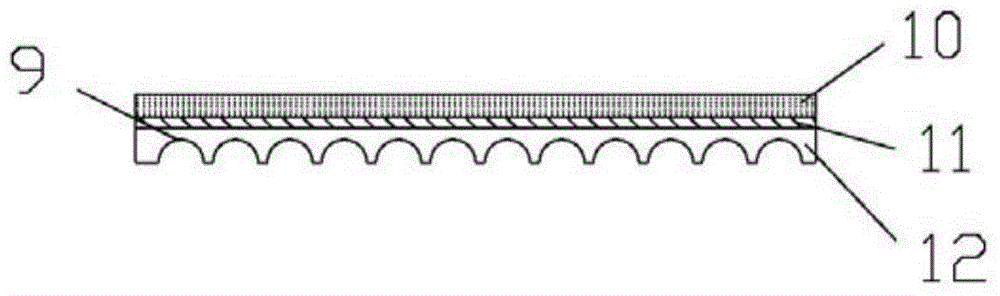

[0015] A paraffin tube shaping device, the device includes a base 7, the lower shaping disc 4 is fixed on the base 7 through two brackets 6, and an upper shaping disc 3 is arranged directly above the lower shaping disc 4; The upper end of the shaping disc 3 is connected to the connecting rod 2, and the connecting rod 2 is connected to the motor 1 and 2 is fixed on the frame 5 through bearings; the upper shaping disc 3 is a plate body 8 with a cavity 12 inside, and one side The surface is provided with a number of semicircular grooves 9; the outermost layer on the other side of the plate body 8 is a shell, and from the outside to the inside are the heating layer 10 and the cavity 12, and the structure of the lower shaping plate 4 is the same as Last shaping dish 3 is identical. The cavity 12 and the heating layer 10 are provided with an insulating layer 9 . The shells of the upper shaping disc 3 and the lower shaping disc 4 are made of stainless steel. The inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com