Method for identifying deviation state of incident laser in online manner

A state, laser technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of limited application, high price, weakening the mechanical properties of sandwich structures, etc., to achieve the effect of wide application and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

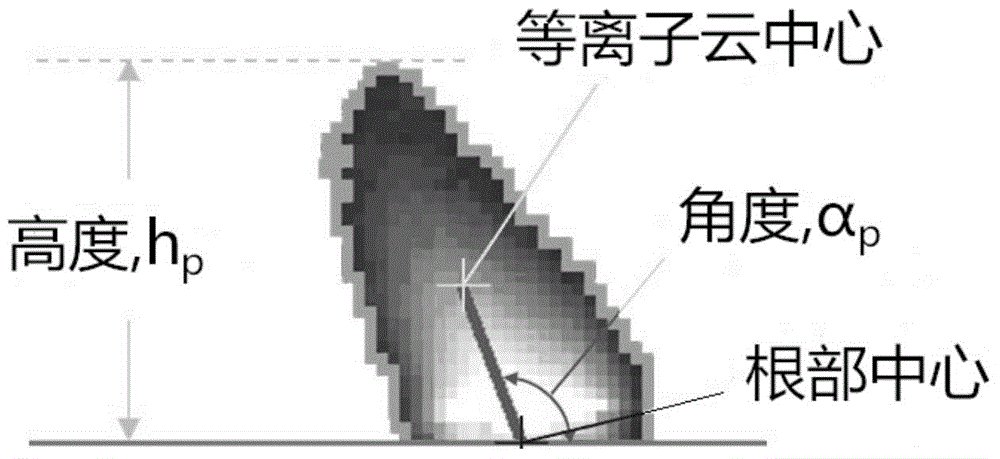

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The examples of the present invention are described in detail below. This example is implemented on the premise of the technical solution of the present invention, and detailed implementation schemes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following examples.

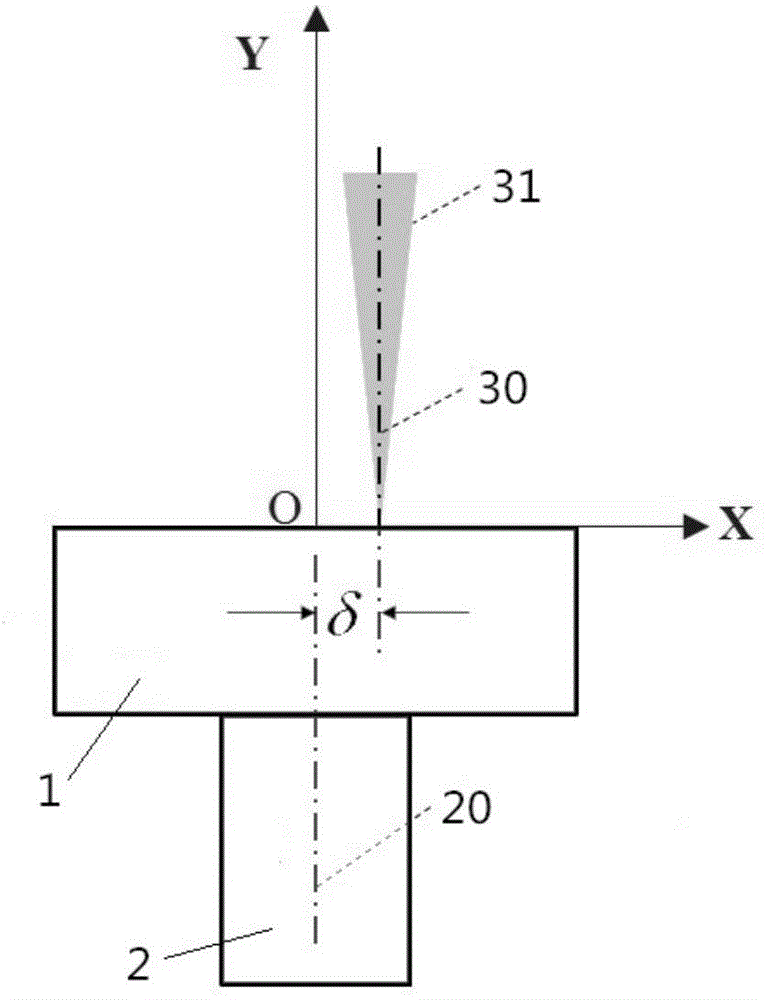

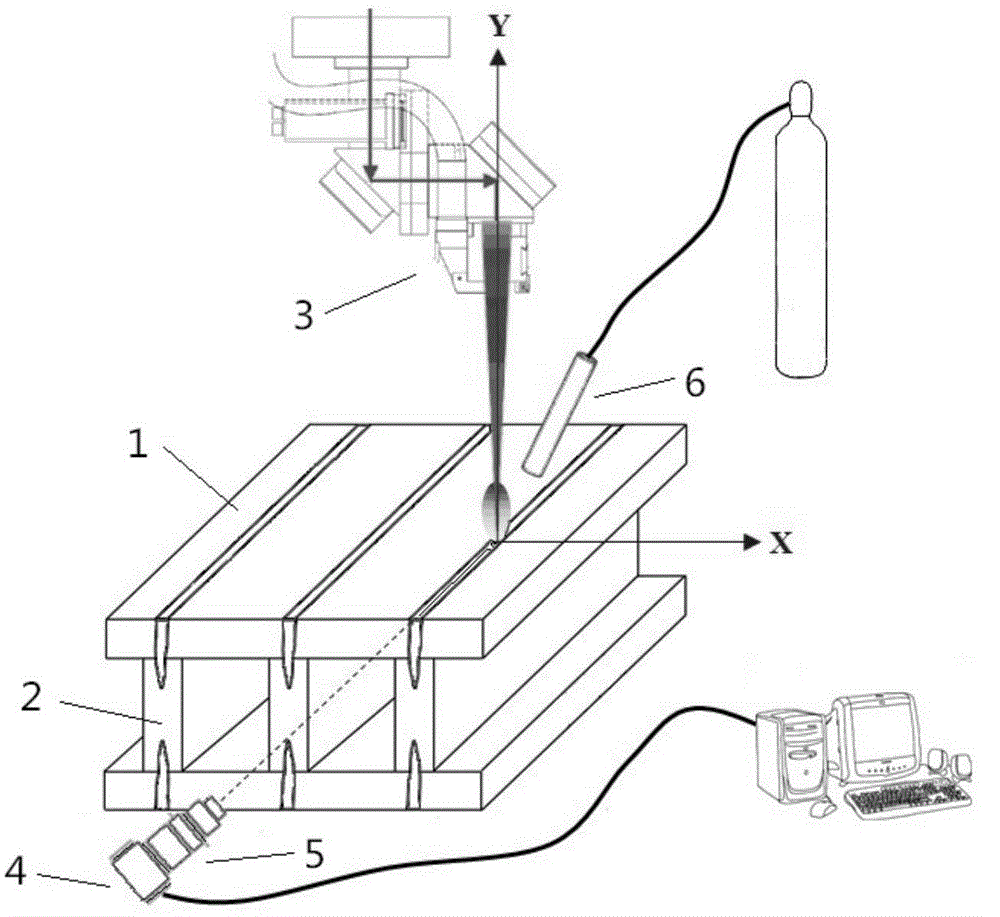

[0034] The invention discloses a method for online recognition of the deviation state of incident laser, which is used for carbon dioxide laser welding of a sandwich structure metal plate. Such as figure 1 As shown, X represents the abscissa and Y represents the ordinate. The incident laser beam 31 is projected onto the panel 1 from the laser working head. The so-called deviation state refers to the distance δ between the incident laser centerline 30 and the core plate centerline 20. During the high-power carbon dioxide laser welding process, if the deviation exceeds a certain range, the connection strength of the panel 1 and the core plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com