Reverse drawing method for soft die with peripheral auxiliary thrust

An auxiliary thrust and reverse drawing technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the friction between the plate and the die, increasing the drawing force, and being unfavorable for forming, and achieves the improvement of forming limit, Ease of sealing, lower cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

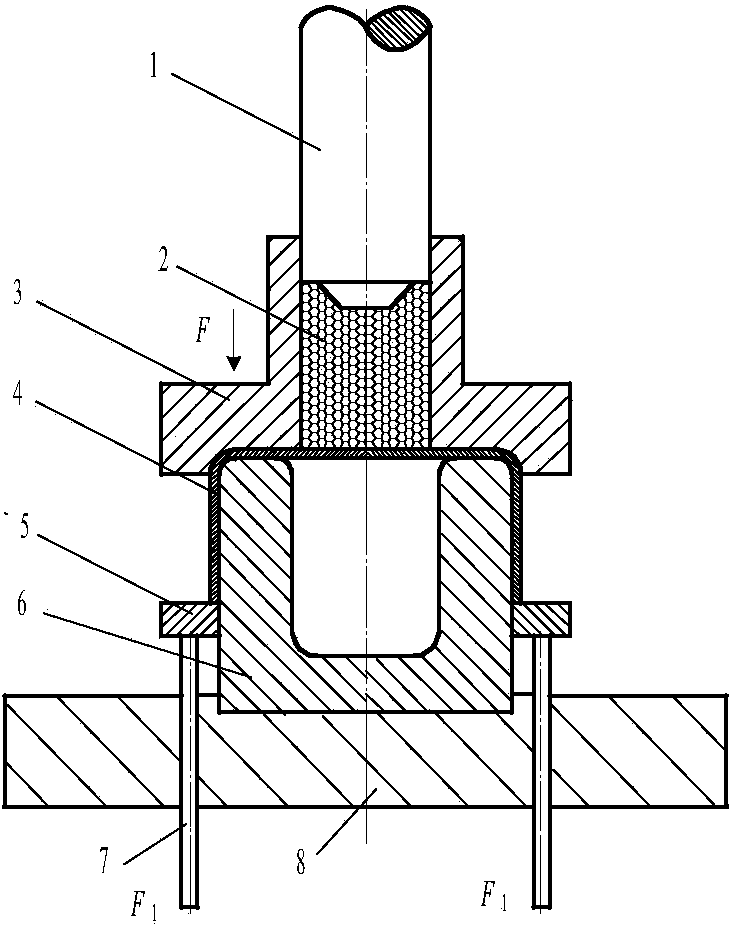

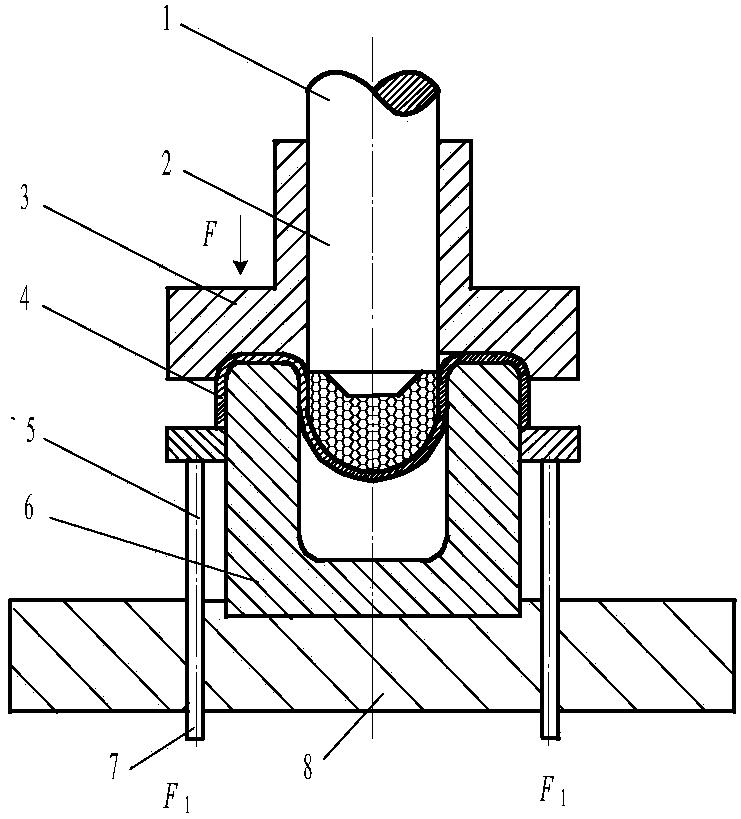

[0017] Fasten the pre-formed 304 stainless steel plate cylindrical part on the die, place the blank holder on the bottom of the cylindrical part and apply a blank holder force F. The granular medium in the barrel is 0.2~0.3mm in diameter Stainless steel ball, the charging height is 1.5 times the diameter of the punch, the punch compresses the medium downward, and applies pressure to the cylindrical part to form a soft punch; at the same time, the 4 ejector rods evenly distributed under the thrust ring are cylindrical The end of the piece provides a circumferential auxiliary thrust F 1 , The force is provided by the hydraulic cylinder, the drawing is finished, and the workpiece is pressed against the inner wall of the cavity to obtain the final shape.

Embodiment 2

[0019] Fasten the pre-formed T2 red copper plate cylindrical part on the die, place the blank holder on the bottom of the cylindrical part and apply a blank holder force F. The granular medium in the barrel is 0.125~0.25mm in diameter Ceramic particles, the charging height is twice the diameter of the punch, the punch compresses the medium downward, and applies pressure to the cylindrical part to form a soft convex mold; at the same time, the 4 ejector rods evenly distributed under the thrust ring are cylindrical The end of the piece provides a circumferential auxiliary thrust F 1 , The force is provided by the pneumatic cylinder, the drawing is finished, and the workpiece is pressed against the inner wall of the cavity to obtain the final shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com