A Venturi rod layer with non-uniform rod spacing

A Venturi rod and non-uniform technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, can solve the problems that the manufacture of circular rings is not as simple as that of straight rods, and achieve obvious effects of increasing efficiency, reducing consumption and saving energy. Improve desulfurization and dust removal efficiency and reduce the effect of liquid-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

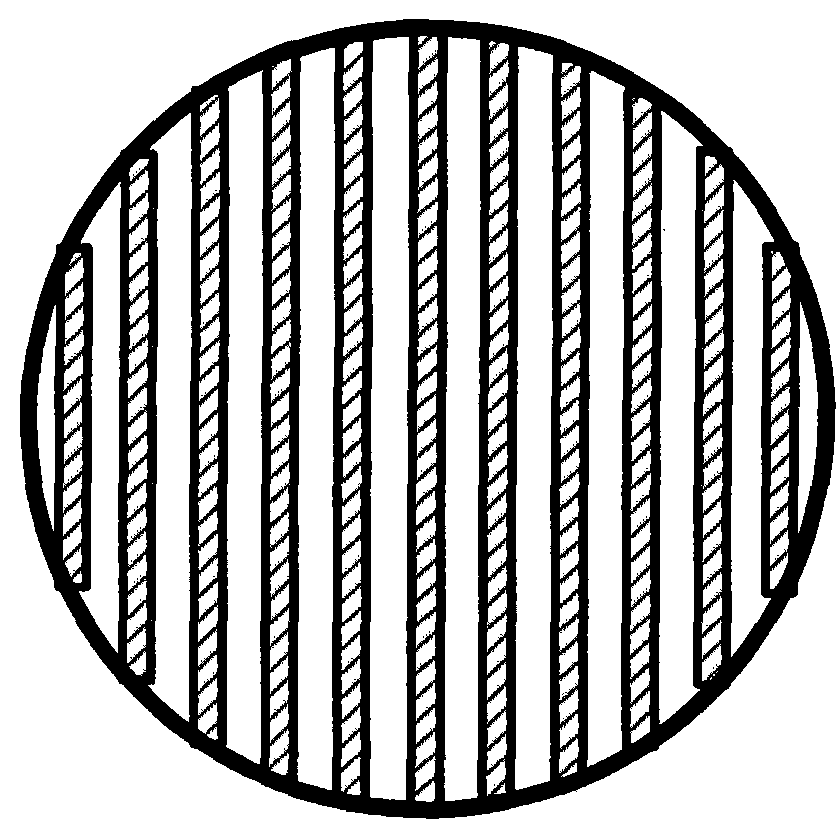

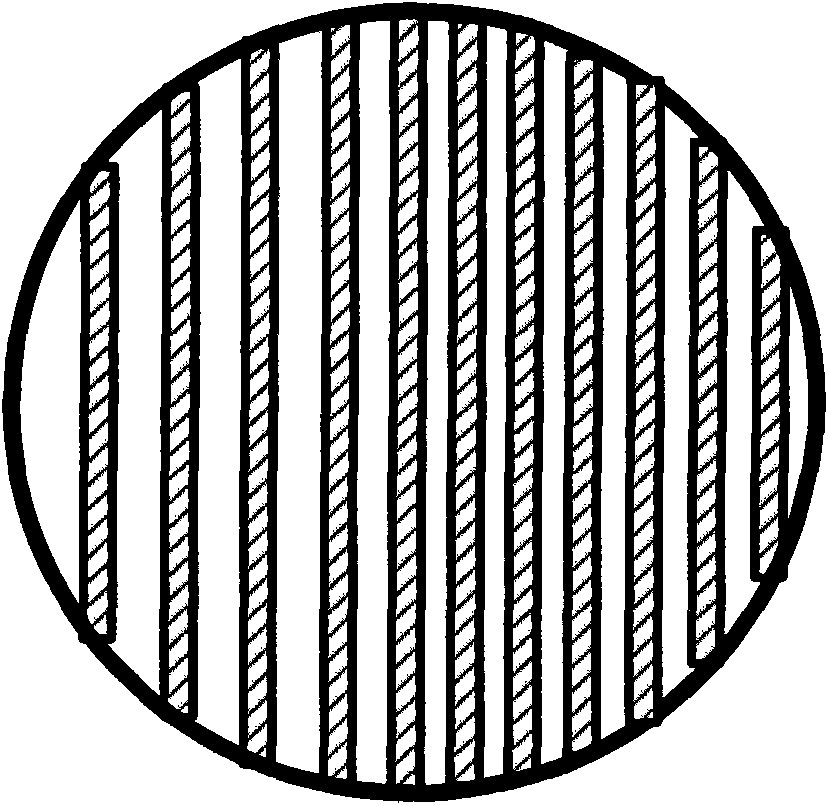

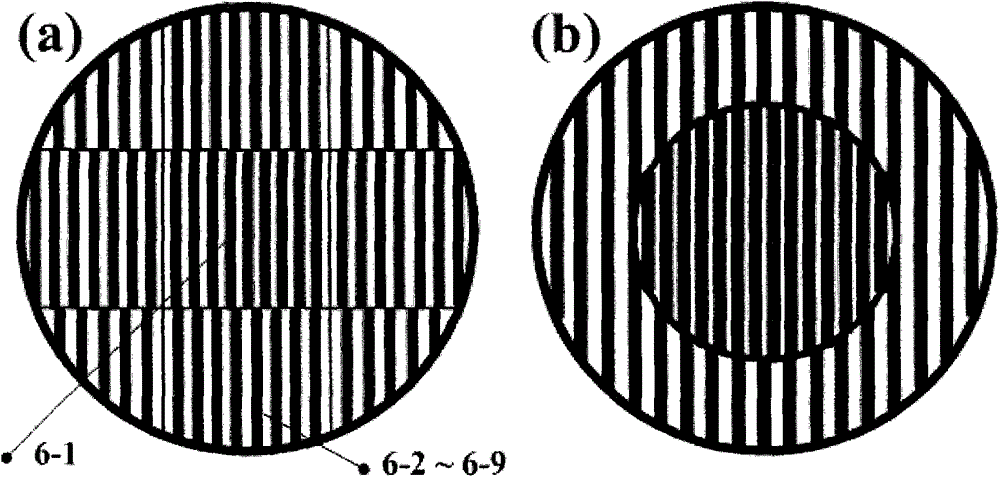

[0017] Such as Figure 4 As shown, in an embodiment of the present invention, a Venturi rod layer 1# with a non-uniform rod pitch covering the full section of the spray absorption tower is installed between the upper end of the absorption tower flue gas inlet section 2 and the spray device 7, and is fixed on the on bracket 3. The ventilation rate (that is, the rod spacing) constituting the 1# layer of the Venturi rods is determined according to the operating parameters of the tower through the numerical simulation of the flow field: starting from the inlet side of the tower, and gradually increasing from 35 to 40% along the diameter D direction of the tower. Decrease, reach about 0.85D position, reduce to 10-15%, and then increase to about 25%. Venturi rod layer 2# is set in the absorption section 5 of the spray tower (the Venturi rod layer 2# can also be omitted, and only Venturi rod layer 1# is set in the whole tower), a non-uniform structure covering the entire cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com