A yellow phosphorus sewage treatment method and device thereof

A sewage treatment method, yellow phosphorus technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of poor separation effect of yellow phosphorus, high dust content, low efficiency of yellow phosphorus sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

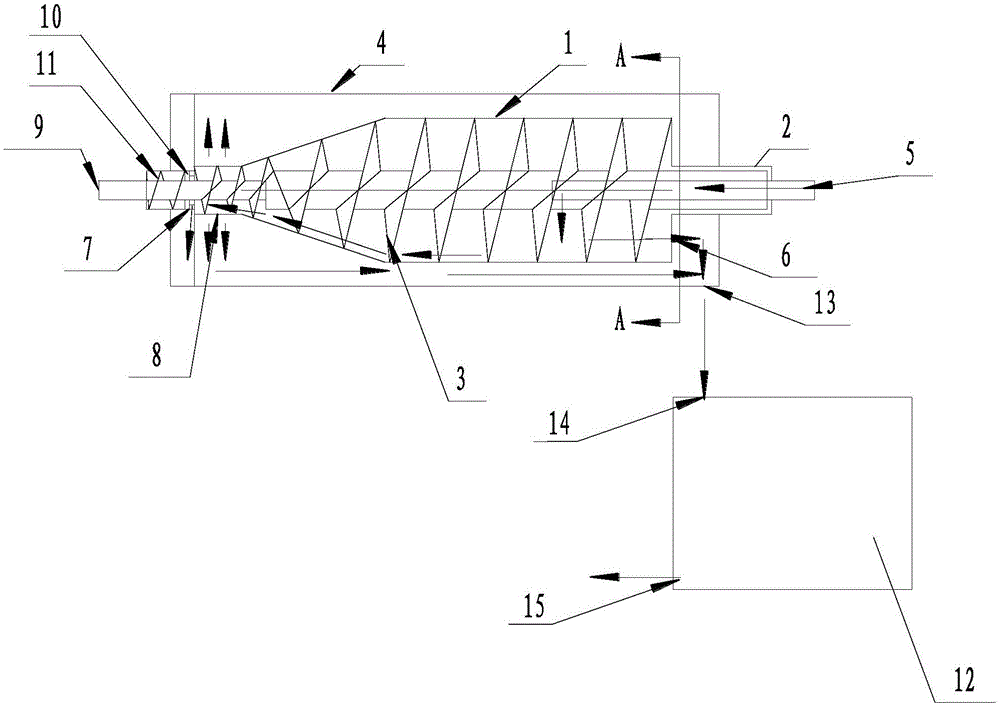

[0058] A device for treating yellow phosphorus sewage, such as figure 2 as shown,

[0059] Including a centrifugal sedimentation separator and a liquid storage tank 12;

[0060] The centrifugal sedimentation separator includes a drum 1, and the drum 1 is a conical-cylindrical drum, such as figure 2 . The left end of the drum 1 is cone-shaped, and the right end is cylindrical. The drum 1 is fixedly installed on the drum rotating shaft 2, and the two ends of the drum rotating shaft 2 are installed on the bearing seat outside the separator shell, and the drum rotates The shaft 2 is located on the axis line of the drum 1 , and the drum 1 rotates around the axis line of the drum rotating shaft 2 .

[0061] The right end of the drum 1 is provided with a feed port 5, which is used to feed yellow phosphorus sewage into the drum 1; the feed port 5 is located on the drum rotation shaft 2, so that the rotation of the drum 1 will not drive The feeding port 5 moves up and down withou...

Embodiment 2

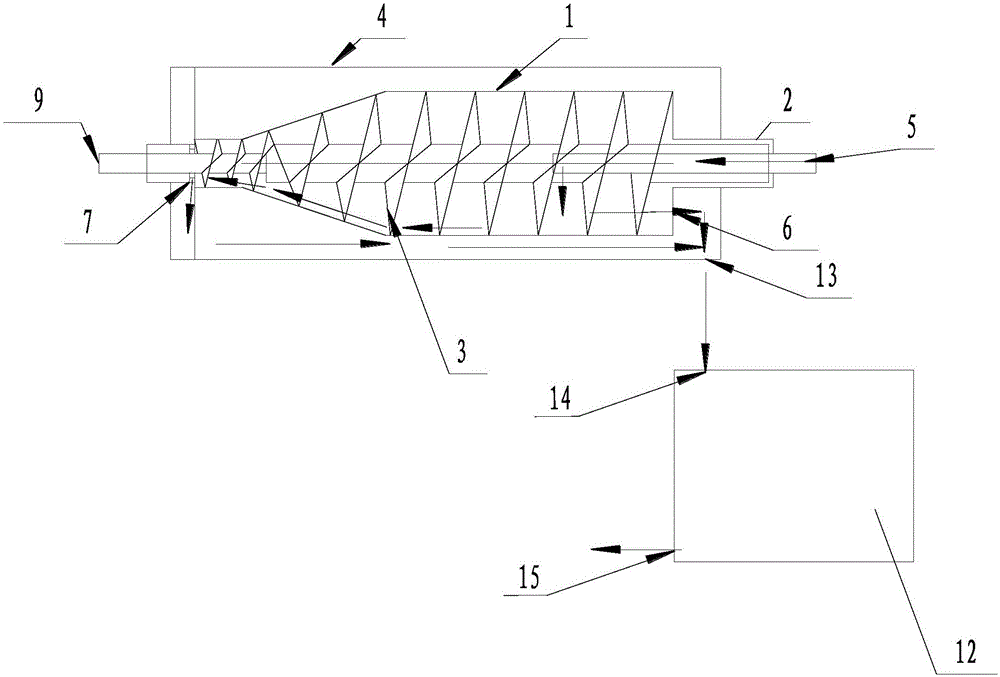

[0072] A device for treating yellow phosphorus sewage, such as image 3 as shown,

[0073] Including a centrifugal sedimentation separator and a liquid storage tank 12; the centrifugal sedimentation separator includes a separator shell liquid outlet 13, and the separator shell liquid outlet 13 is located at the upper end of the liquid storage tank 12;

[0074] The centrifugal sedimentation separator includes a drum 1, and the drum 1 is a conical-cylindrical drum, such as image 3 , the left end of the drum is cone-shaped, and the right end is cylindrical. The drum 1 is fixed on the drum rotating shaft 2. The drum rotating shaft 2 is installed on the bearing seat outside the drum 1 and is located at the axis of the drum 1. On the line, the drum 1 rotates around the axis of the drum rotation shaft 2 .

[0075] One end of the drum 1 is provided with a feeding port 5, which is used to feed yellow phosphorus sewage into the drum 1; the feeding port 5 is located on the rotating sh...

Embodiment 3

[0084] The process flow of the yellow phosphorus sewage treatment method of the present embodiment is as figure 1 as shown, figure 1 The separation device in is the device for the treatment of yellow phosphorus sewage in embodiment 1, such as figure 2 shown.

[0085] The yellow phosphorus sewage treatment process of the present embodiment comprises:

[0086] The yellow phosphorus sewage from the phosphorus receiving tank and the refined pot contains yellow phosphorus, water and dust. The dust wraps or absorbs yellow phosphorus, and the yellow phosphorus sewage goes to the centrifugal sedimentation separator for centrifugal separation. After separation, solid phosphorus slag and liquid yellow phosphorus are obtained. and water; the liquid containing liquid yellow phosphorus and water goes to the liquid storage tank to stand for stratification, and after separation, yellow phosphorus and deslagging water are obtained. The specific operation steps are as follows:

[0087] Be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com