Printed circuit board buried resistor machining method

A technology of printed circuit boards and processing methods, which is applied in the direction of containing printed electrical components and removing conductive materials by chemical/electrolytic methods, which can solve the problem of affecting wiring density, wasting materials, and the accuracy and consistency can only be controlled within 25 % and other problems, to achieve high precision and consistency, improve wiring density, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

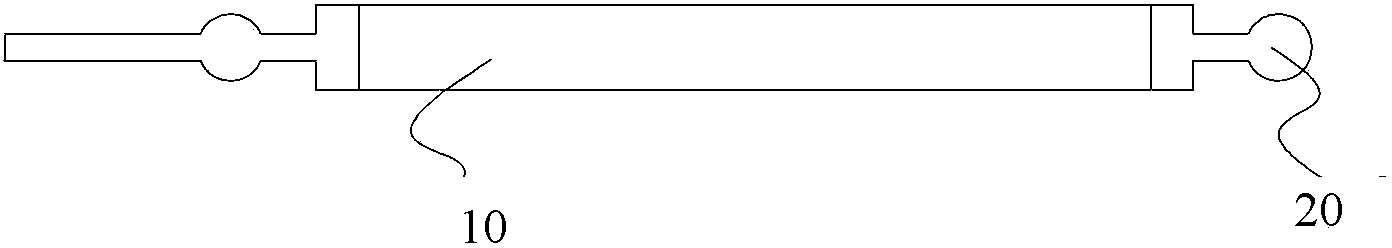

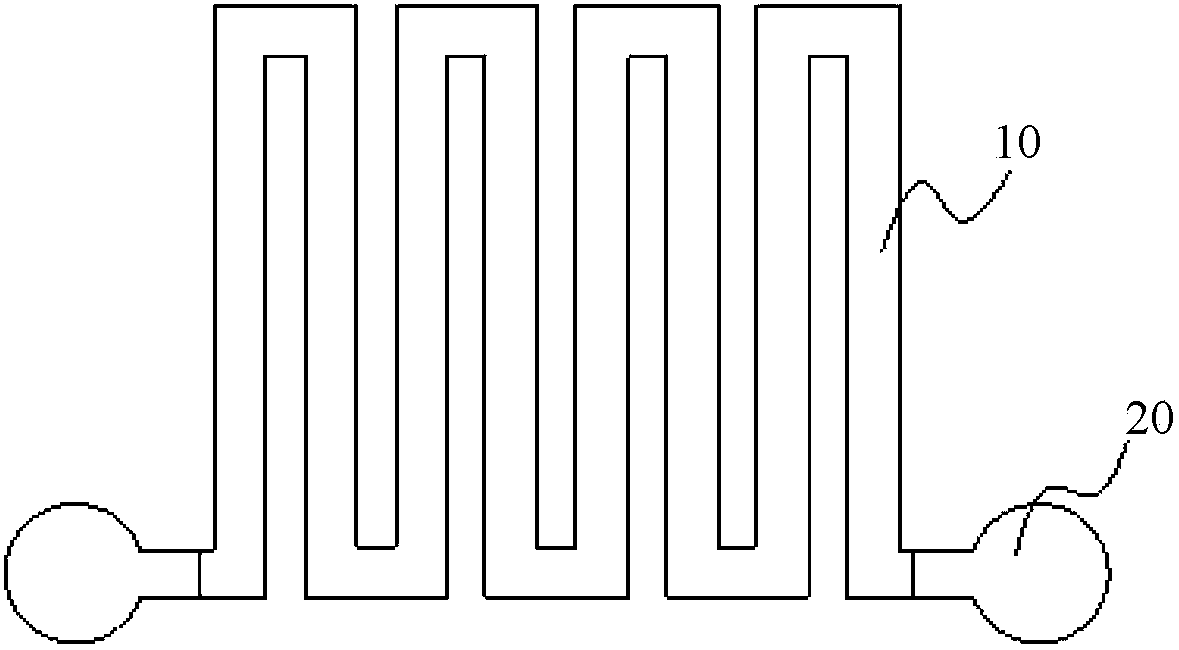

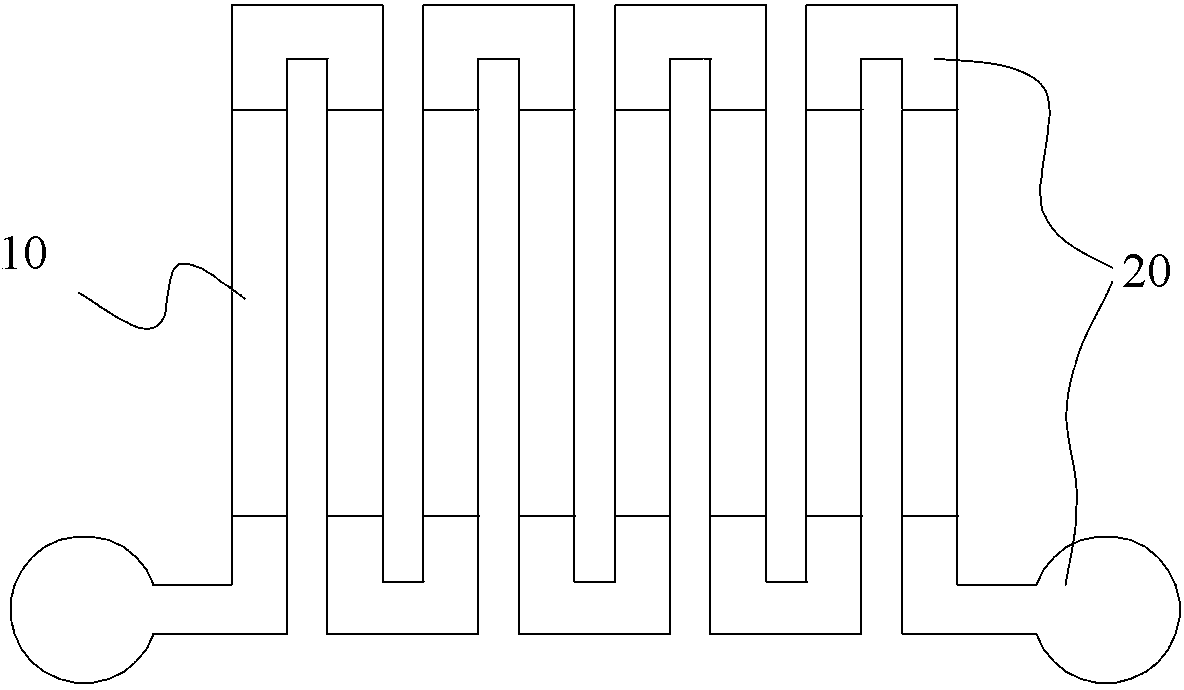

[0084] see Figure 10 ~ Figure 18 , an embodiment of the method for processing buried resistors in printed circuit boards of the present invention, which adopts a material with a square resistance of 50 ohms, and processes a target resistance of 250 ohms.

[0085] The resistance value of the resistor is calculated by the following formula (I):

[0086] R=(b / a)×R S (I)

[0087] Among them; R S =ρ / H, the resistance width a is set to 100 μm, then the resistance etching length b is 250 / 50×100=500 μm.

[0088] Specific steps are as follows:

[0089] 1) Resistance copper foil lamination

[0090] The 50 ohm square resistance, the resistance copper foil 2 containing the resistance layer material 1, and the dielectric material 3 are pressed onto the substrate 8 on which the circuit pattern has been made, and the resistance layer material 1 is formed be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com