Preparation system and preparation method for high-performance fiber multi-axial fabric preform

A high-performance fiber and preform technology, which is applied in the field of preparation system of high-performance fiber multi-axial fabric preform, can solve the problems of low efficiency and unguaranteed accuracy, so as to reduce labor, ensure consistency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

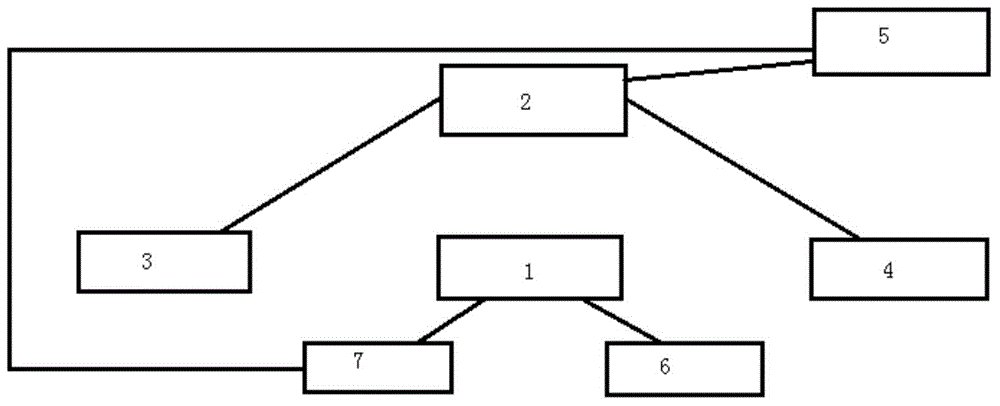

[0040] See figure 1 , the preparation system of the high-performance fiber multi-axial fabric preform of the present embodiment includes a mold cavity 1, a first mechanical arm 2, a first cutting machine 3, a second cutting machine 4, a main control machine 5, a molding press machine 6 and sonic cutter 7; the first mechanical arm 2 is controlled alternately by the main control machine 5 to move from the first cutting machine 3 to the mold cavity 2 and from the second cutting machine 4 to the mold cavity 1; the first The distance between the mechanical arm 2 and the first cutting machine 3 and the second cutting machine 4 ≤ the working distance of the first mechanical arm 2 . The molding machine 6 and the sonic cutter 7 are connected with the main control machine 5 in communication. A laser transmitter is arranged at the center of the mold cavity 1; a laser receiver is arranged at the end of the first mechanical arm 2. There are two pairs of grasping claws of the first mechan...

Embodiment 2

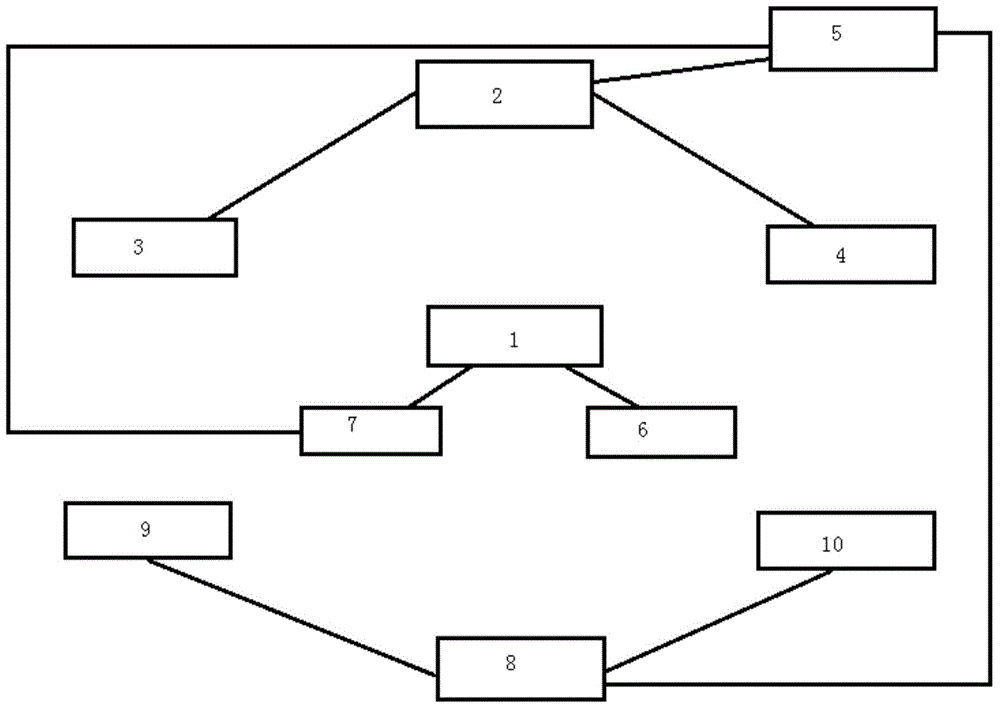

[0048] See figure 2, the preparation system of the high-performance fiber multiaxial fabric preform of this embodiment, on the basis of Embodiment 1, also includes a second mechanical arm 8, a third cutting machine 9 and a fourth cutting machine 10; Three cutting machines 9 and the fourth cutting machine 10 are arranged opposite to the first cutting machine 3 and the second cutting machine 4 respectively; 9 to the mold cavity 2 and from the fourth cutting machine 10 to the movement of the mold cavity 1; the distance between the second mechanical arm 8 and the third cutting machine 9 and the fourth cutting machine 10 ≤ the distance between the second mechanical arm 8 Working distance; mold cavity 1 is arranged between the first cutting machine 3, the second cutting machine 4, the third cutting machine 9 and the fourth cutting machine 10, and is connected with the first cutting machine 3, the second cutting machine The cutting machine 4, the third cutting machine 9 and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com