Novel High-reliability surge protector

A surge protector and reliability technology, which is applied in the field of high-reliability new surge protectors, can solve the problems of thermal detachment response time lag, high heat conduction time, spouting and burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

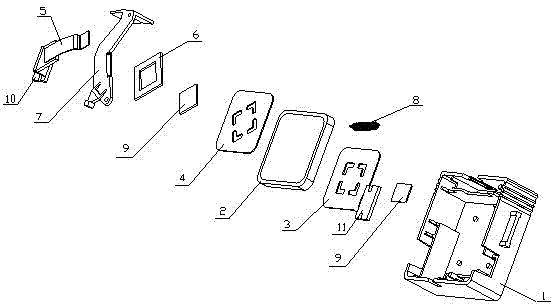

[0016] Embodiment 1, as figure 1 As shown, the core varistor 2 of this embodiment is a 34×34mm square chip, the varistor voltage of the varistor 2 is 620V, and its power frequency breakdown point is in the middle of the chip, and the two electrodes of the varistor 2 are respectively connected to Electrode A3 and internal electrode B4, the thermal detachment point area of internal electrode B4 is connected with epoxy resin baffle plate 6, except that the height of epoxy resin baffle plate 6 is 1-3mm, makes it after potting with liquid epoxy resin like this When insulated, it is blocked by the epoxy resin baffle 6, except the area of the epoxy resin baffle 6, the other areas of the varistor 2 and the connected inner electrode A3 and inner electrode B4 are potted with liquid epoxy resin to form a main body. In the protector, one electrode of the piezoresistor 2 is connected to the thermal detachment shrapnel 5 through the thermal detachment point in the middle of the inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com