A two-dimensional phase change memory cell structure and its manufacturing method

A phase change memory and cell structure technology, applied in electrical components and other directions, can solve the problems of inability to realize energy consumption, low phase change memory cells, etc., and achieve the effects of ultra-low non-volatile information storage and ultra-low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

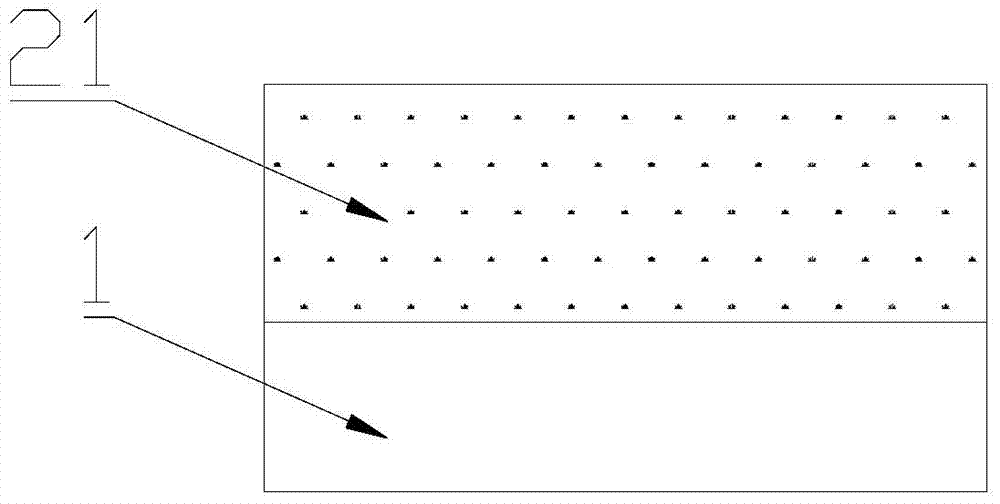

[0056] Figure 10 It is a structural schematic diagram of the phase change memory cell structure of this embodiment; as Figure 10 As shown, a phase-change memory cell structure includes: a substrate wafer 1; a first insulating layer 21 arranged above the substrate wafer 1, a lower electrode 3 is arranged in the first insulating layer 21, and a lower electrode 3 is placed under the lower electrode 3. The surface connection substrate wafer 1; the phase change structure 7 disposed above the first insulating layer 21 and the lower electrode 3; the second insulating layer 22 disposed above the phase change structure 7 and the first insulating layer 21, and the phase change structure 7 It includes a first phase-change auxiliary layer 71 , a phase-change material layer 72 and a second phase-change auxiliary layer 73 disposed above the bottom electrode 3 in sequence.

[0057] Among them, the substrate wafer 1 is a wafer prepared with a phase-change memory circuit, and the substrate ...

Embodiment 2

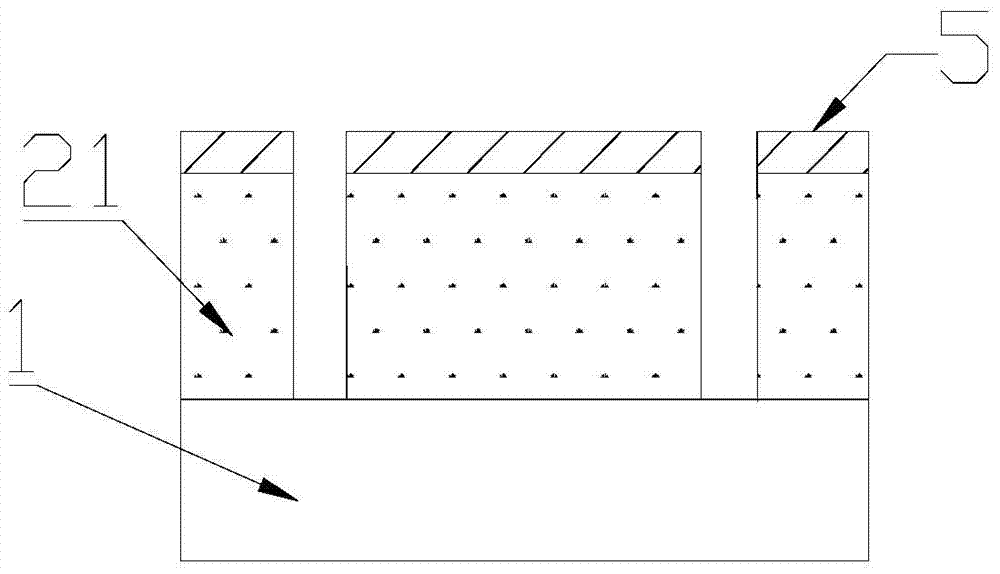

[0068] Figure 16 It is a structural schematic diagram of the phase change memory cell structure of this embodiment; as Figure 16 As shown, a phase change memory cell structure includes: a substrate wafer 1; a first insulating layer 21 arranged above the substrate wafer 1, and two lower electrodes 3 are arranged in the first insulating layer 21, and the lower electrode 3 The lower connection substrate wafer 1, the second insulating layer 22 disposed above the first insulating layer 21 and the lower electrode 3, the phase change structure 7 disposed in the second insulating layer 22, the phase change structure 7 An upper electrode 8 located above the lower electrode 3 and disposed above the phase change structure 7, wherein the phase change structure 7 includes a first phase change auxiliary layer, a phase change material layer and a second phase change layer sequentially disposed above the lower electrode 3 Change auxiliary layer.

[0069] The preparation method of the phas...

Embodiment 3

[0076] like Figure 16 As shown, the structure and preparation method of the present embodiment are similar to those of the second embodiment, the difference is that there is only one bottom electrode 3, and the phase change structure 7 is a square structure, which will not be repeated here.

[0077] In summary, in the above-mentioned embodiments, the phase-change material layer of the phase-change memory unit is sandwiched between two phase-change auxiliary layers, and the phase-change material layer is extremely thin, with a thickness of 0.1nm-10nm, within a few atomic layers. Between dozens of atomic layers, the phase-change material layer can achieve better lattice matching and auxiliary phase-change effect with the phase-change material. When the phase-change memory is working, under the action of electric and thermal fields, the phase-change material layer It does not need to reach a molten state, and can achieve low-energy non-volatile information storage through a phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com