Transparent flexible electrochemical device based on planar comb-shaped electrode structure, and preparation method thereof

A comb-tooth-shaped electrode and a planar electrode technology are applied in the field of transparent flexible electrochemical devices and their preparation, which can solve the problems of difficult and large-area production, detachment of active material layers, etc., and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

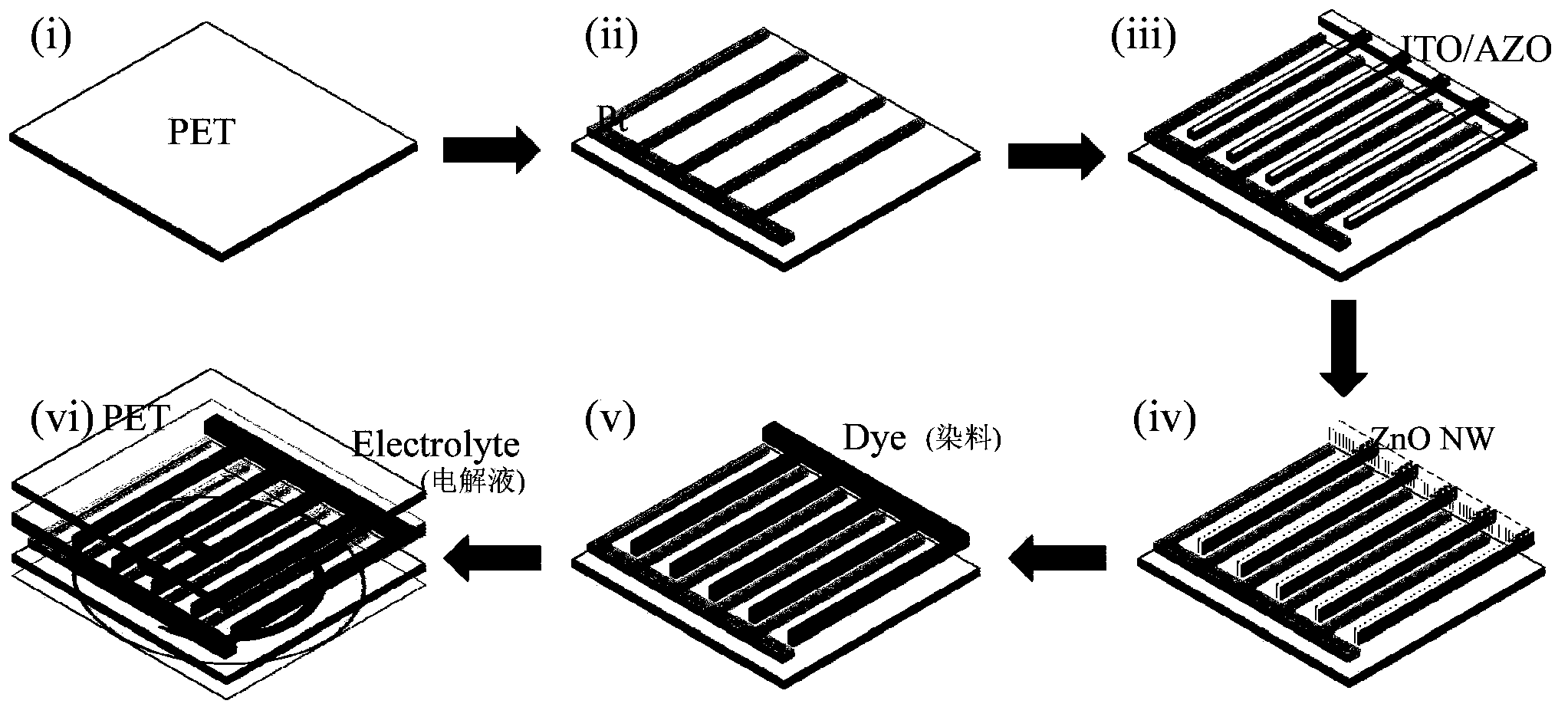

[0054] Example 1. Preparation of transparent and flexible dye-sensitized solar cells

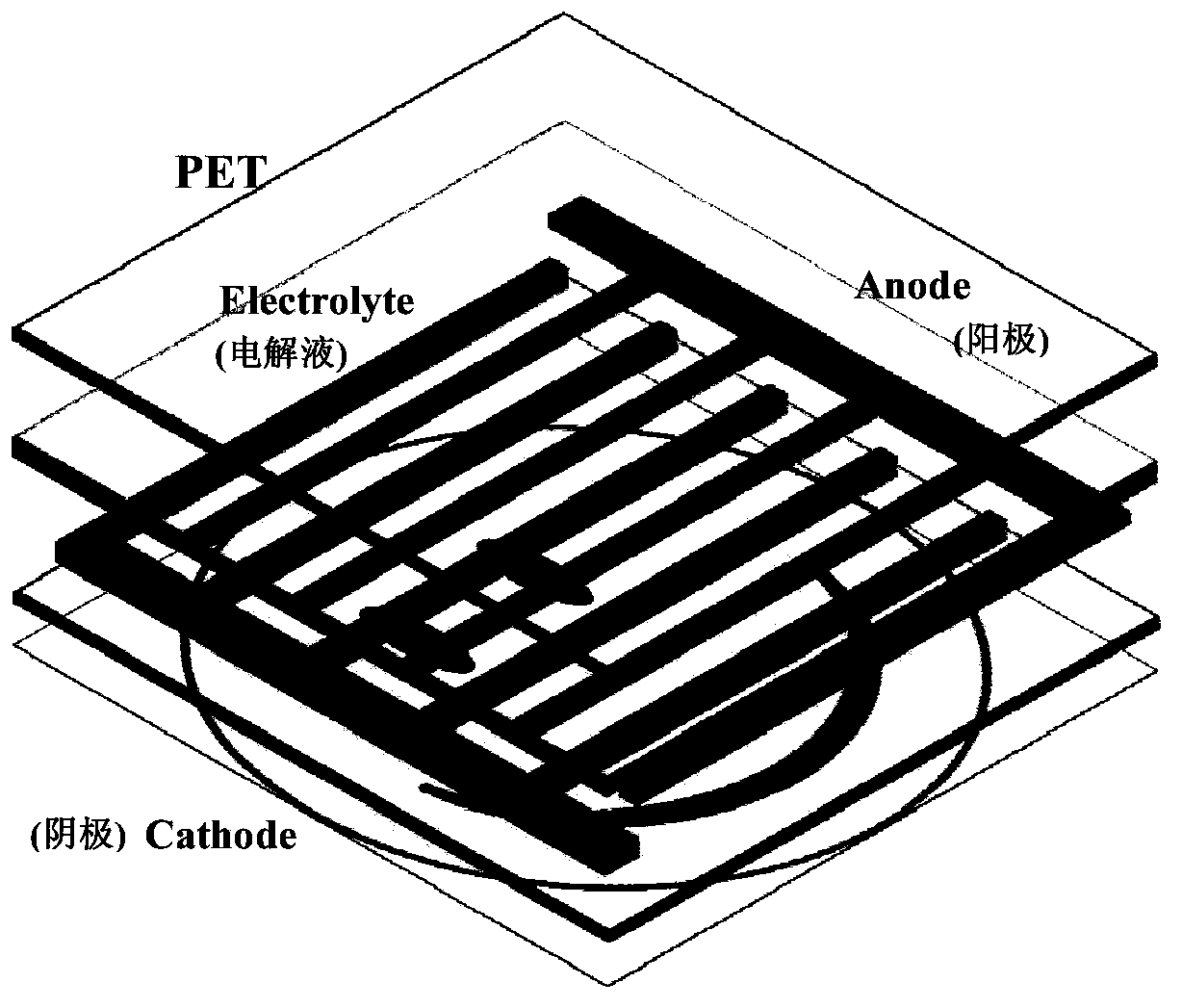

[0055] The transparent and flexible dye-sensitized solar cell comprises a planar electrode, an electrolyte filled into the planar electrode, and a transparent flexible PET substrate for encapsulating the planar electrode and the electrolyte; the anode in the planar electrode It is a zinc oxide nanowire array deposited on the surface of the ITO film, and the zinc oxide nanowire has absorbed N719 dye; the cathode is a platinum electrode;

[0056] The planar electrode includes an anode and a counter electrode located on the same transparent flexible PET substrate; the anode and the counter electrode are comb-toothed electrodes and are mutually parallel electrodes, and the anode and the comb-toothed electrodes of the counter electrode are mutually Arranged crosswise, the width of the teeth in the comb-toothed electrodes is 60 microns, and the distance between adjacent teeth in the comb-toothed e...

Embodiment 2

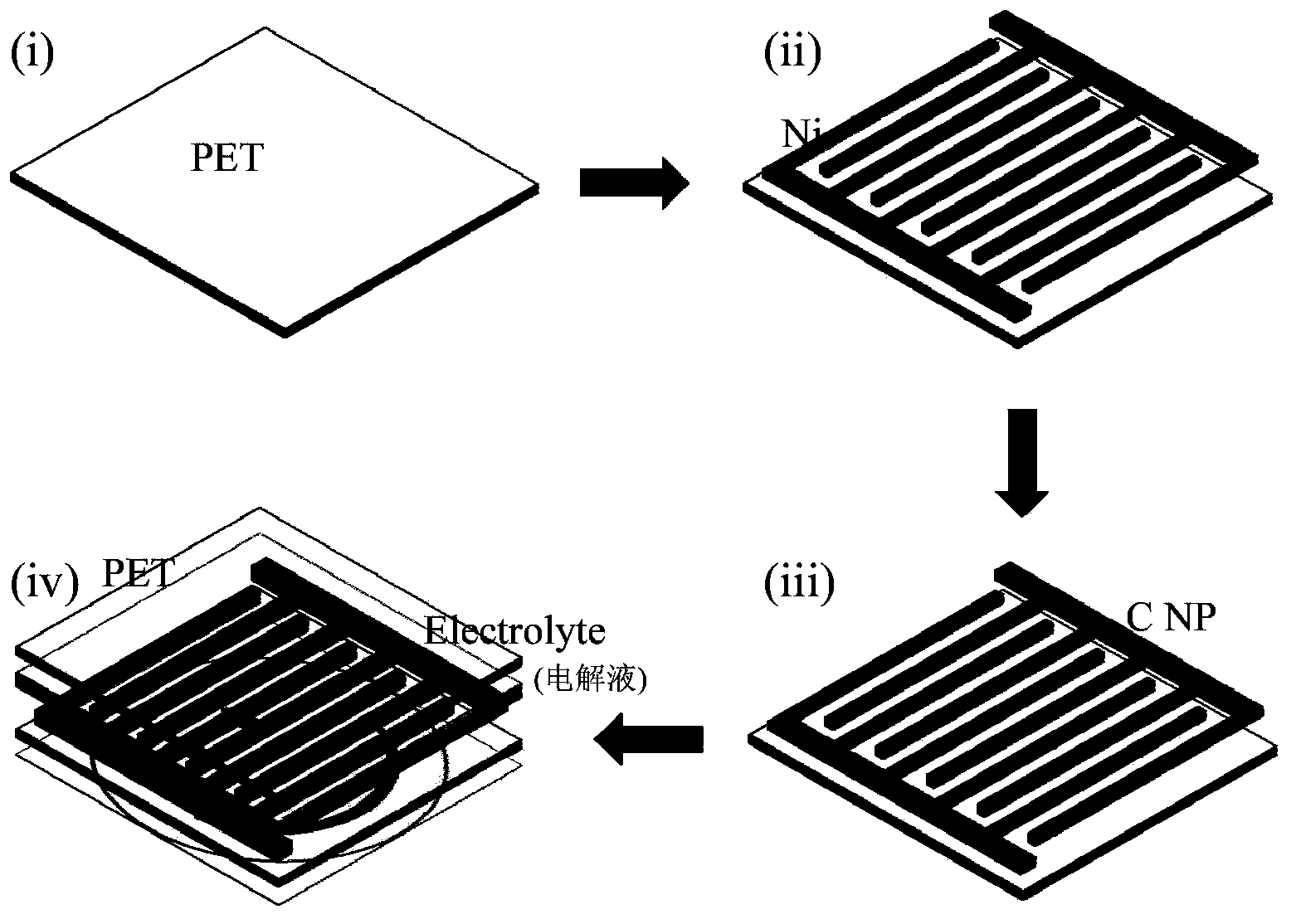

[0068] Embodiment 2, prepare transparent flexible supercapacitor

[0069] The supercapacitor comprises a planar electrode and an electrolyte filled into the planar electrode and a transparent flexible substrate for encapsulating the planar electrode and the electrolyte; the anode and the cathode in the planar electrode are deposited on a nickel film carbon nanoparticles;

[0070] The planar electrode includes an anode and a cathode arranged on the same transparent flexible PET substrate; both the anode and the cathode are comb-shaped electrodes and are parallel electrodes, and the comb-tooth electrodes of the anode and the cathode are arranged to cross each other, The width of the teeth in the comb-toothed electrodes is 100 microns, and the distance between adjacent teeth in the comb-toothed electrodes that are relatively cross-arranged is 100 microns; the racks of the anodes are connected together by the collecting electrodes at the outer ends, As an anode collector electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com