Special cable of automatic welding robot

A special cable, automatic welding technology, used in welding equipment, insulated cables, welding equipment and other directions, can solve the problems of automatic welding robot line disorder, long wiring time, inconvenient use, etc. Material, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

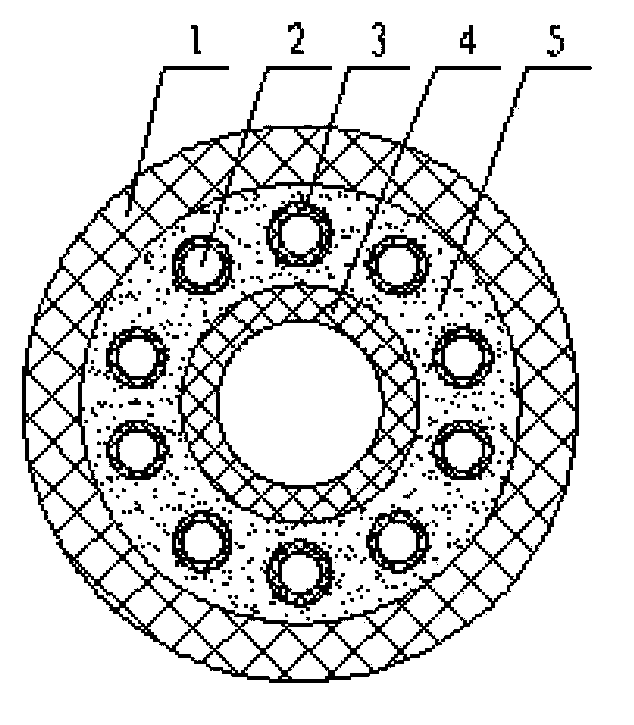

[0020] A special cable for an automatic welding robot, comprising an outer sheath 1, a welding conductor 5 and a control wire core. The outer sheath is an insulating outer sheath made of radiation cross-linked special elastomer material. The welding conductor is a high-purity Ф0.20mm oxygen-free copper conductor. The control wire core is composed of a control wire core conductor 2 and a control wire core insulation layer 3 wrapped outside the control wire core conductor. The control wire core conductor is tinned copper wire, and the control wire core insulation layer is a radiation cross-linked special elastomer formed insulating layer. The number of control wire cores is not limited, two or more according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com