Cargo handling method for Baosteel-Haier supply chain

A processing method and supply chain technology, applied in data processing applications, logistics, instruments, etc., can solve the problems of stagnant sales of Baosteel products, loss of inventory and logistics costs, and small unit consumption of materials, so as to save logistics transportation costs and simplify logistics. Transportation management, the effect of meeting actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Taking the cargo handling of Baosteel-Haier Material Control Park as an example to discuss in detail:

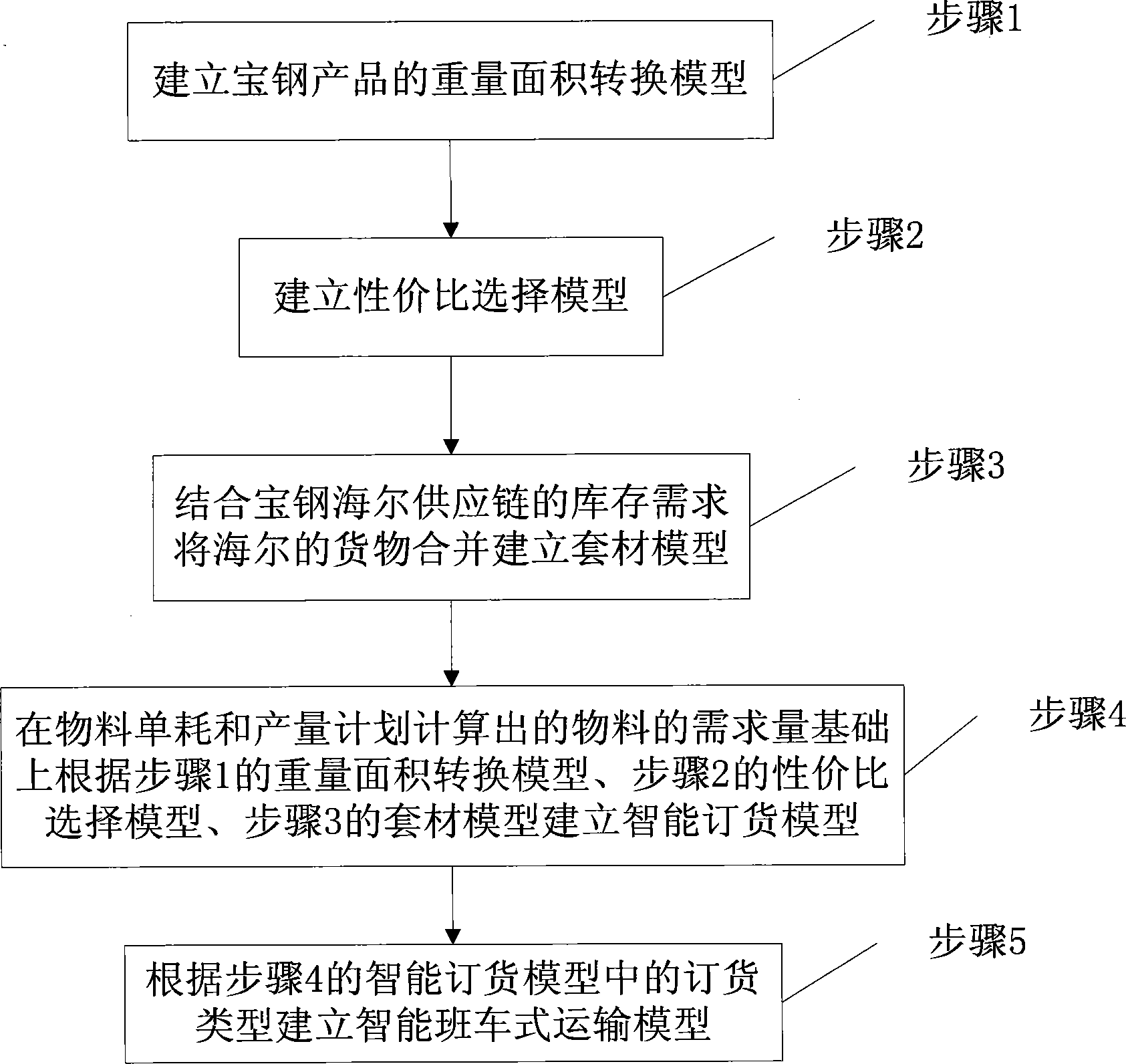

[0046] Step 1, establishing a weight-area conversion model;

[0047] Model formula:

[0048] m=ρ*t*w*l 1)

[0049] S=m\ρ\t=w*l 2)

[0050] Among them, the steel weight of Baosteel products is m, ρ is the steel density of Baosteel products, t is the steel thickness of Baosteel products, w is the steel width of Baosteel products, 1 is the steel length of Baosteel products, S is the steel area of Baosteel products ;

[0051] Basic data preparation: compare the area and density of each special number of cut-to-length material with the steel type (accurate to the influence of the galvanized layer).

[0052] Step 2, establishing a cost-effective selection model;

[0053] Model formula:

[0054] P i =P*m\ρ\t 3)

[0055] P min =Min(p 1 ......p i ) 4)

[0056] Among them, the unit price of Baosteel products settled by area is Pi, the unit price of Baosteel produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com