Active energy ray-cured resin compound, and coloring partition and black matrix for display element

An active energy ray, curable resin technology, applied in the field of black matrix, can solve the problems of poor voltage holding rate, not voltage, etc., and achieve the effects of excellent adhesion, high radiation sensitivity, and excellent developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

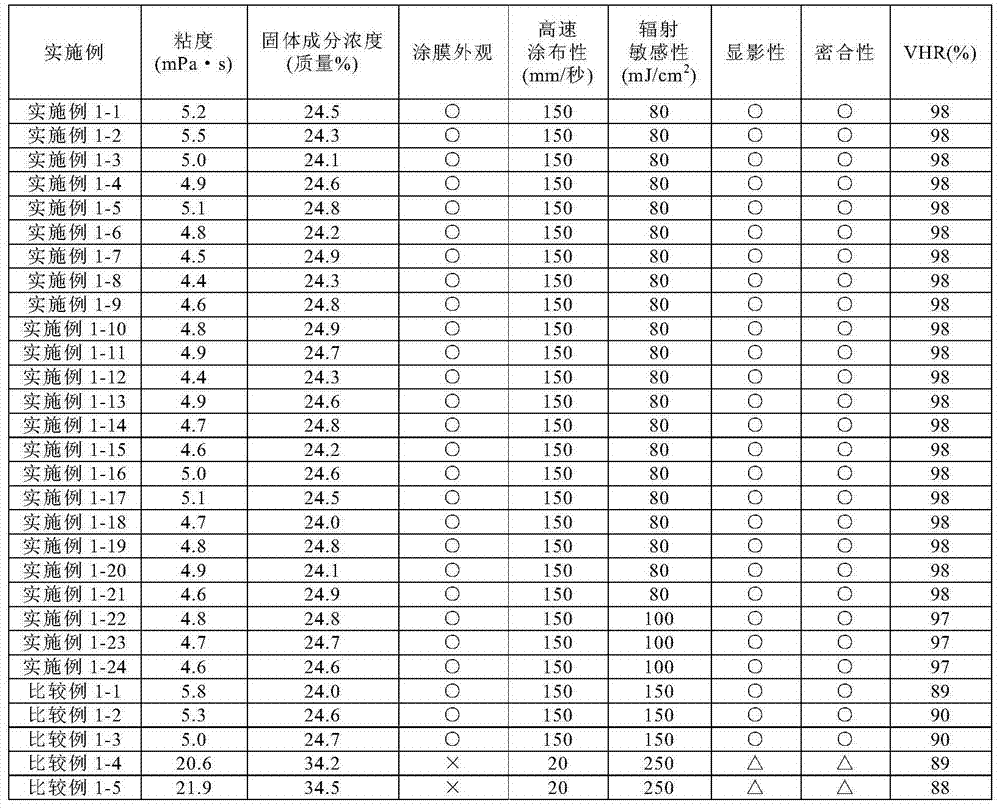

Examples

Embodiment

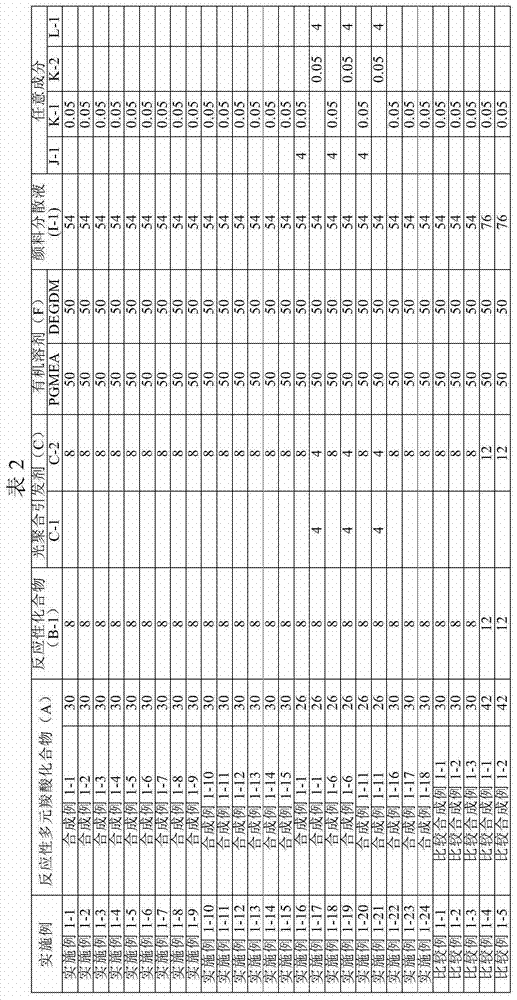

[0170] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited by these examples. In addition, in the examples, "parts" represent parts by mass unless otherwise specified.

[0171] The softening point, epoxy equivalent, and acid value were measured under the following conditions.

[0172] 1) Epoxy equivalent: measured by the method according to JIS K7236:2001

[0173] 2) Softening point: Measured by a method according to JIS K7234:1986

[0174] 3) Acid value: Measured by the method according to JISK0070:1992

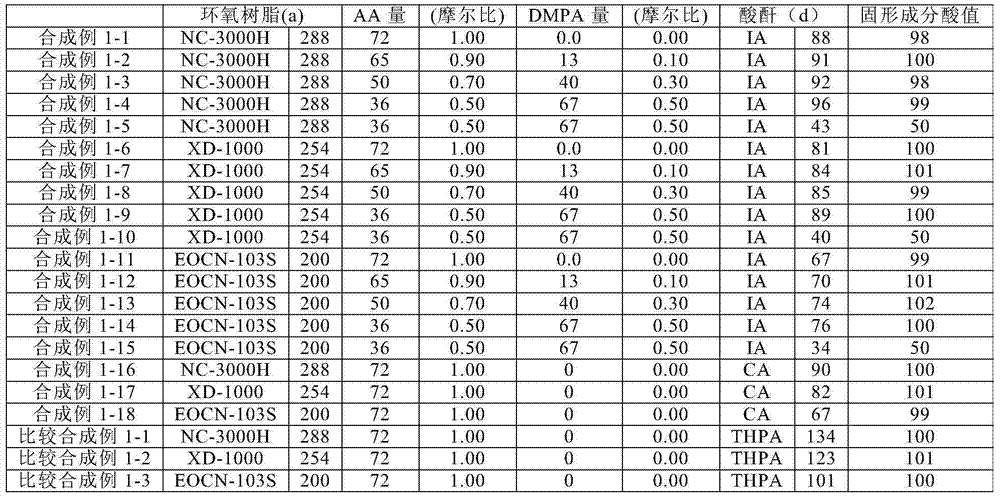

Synthetic example 1-1~1-18

[0175] Synthesis examples 1-1 to 1-18: Preparation of reactive polycarboxylic acid compound (A)

[0176] NC-3000H (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288 g / eq) and XD-1000 (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 254 g) were added as epoxy resin (a) in the amount described in Table 1 / eq), EOCN-103S (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 200g / eq), and acrylic acid (AA for short, Mw=72) as compound (b) was added in the amount recorded in Table 1. Dimethylolpropionic acid (DMPA for short, Mw=134) was added as the compound (c) in the amount described in . 3 g of triphenylphosphine was added as a catalyst, and propylene glycol monomethyl ether monoacetate was added as a solvent so that the solid content became 80% by mass of the reaction liquid. React at 100° C. for 24 hours to obtain a reactive epoxy carboxylate compound (G) solution. The next reaction was performed with a solid content acid value (AV: mgKOH / g) of 5 o...

Synthetic example 1-1~1-3

[0178] Comparative Synthesis Examples 1-1 to 1-3: Preparation of Comparative Reactive Polycarboxylic Acid Compounds

[0179] NC-3000H (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288 g / eq), XD-1000 (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 254 g / eq), EOCN-103S ( Manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 200 g / eq), acrylic acid was added as compound (b) in the amount described in Table 1, 3 g of triphenylphosphine was added as a catalyst, and propylene glycol monomethyl ether was added as a solvent Monoacetate made the solid content 80 mass % of the reaction liquid. It reacted at 100 degreeC for 24 hours, and obtained the carboxylate compound solution. The next reaction was performed with the solid content acid value (AV: mgKOH / g) being 5 mgKOH / g or less as the reaction end point.

[0180] Then, tetrahydrophthalic anhydride (abbreviated as THPA) as a polybasic acid anhydride was added to the reactive epoxy carboxylate compound so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com