Reactor Fiber Bragg Grating Temperature Measurement Device

A fiber grating and temperature measuring device technology, applied in the direction of measuring devices, instruments, thermometers, etc., can solve the problems that the actual temperature of the package cannot be truly reflected, the detector cannot be maintained, etc., and achieve strong antimagnetic, easy to disassemble, The effect of a large temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

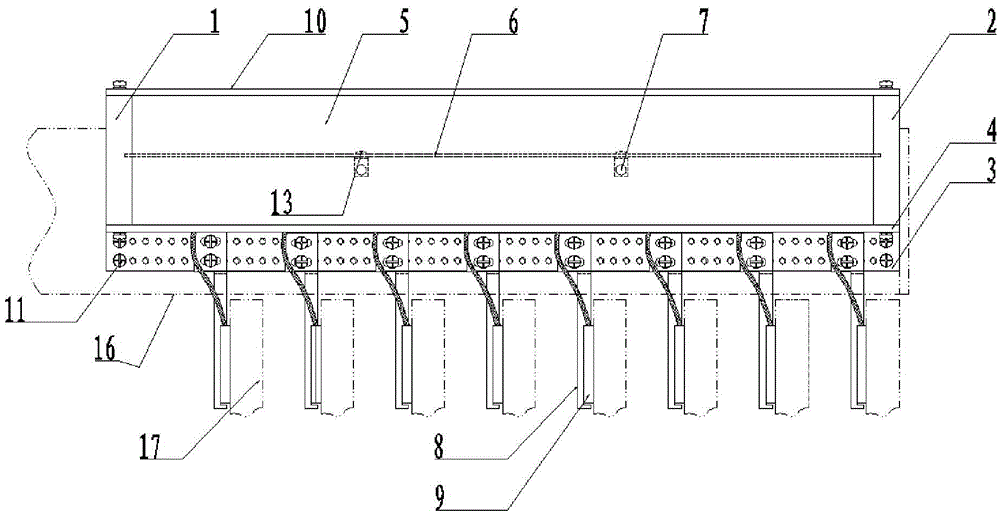

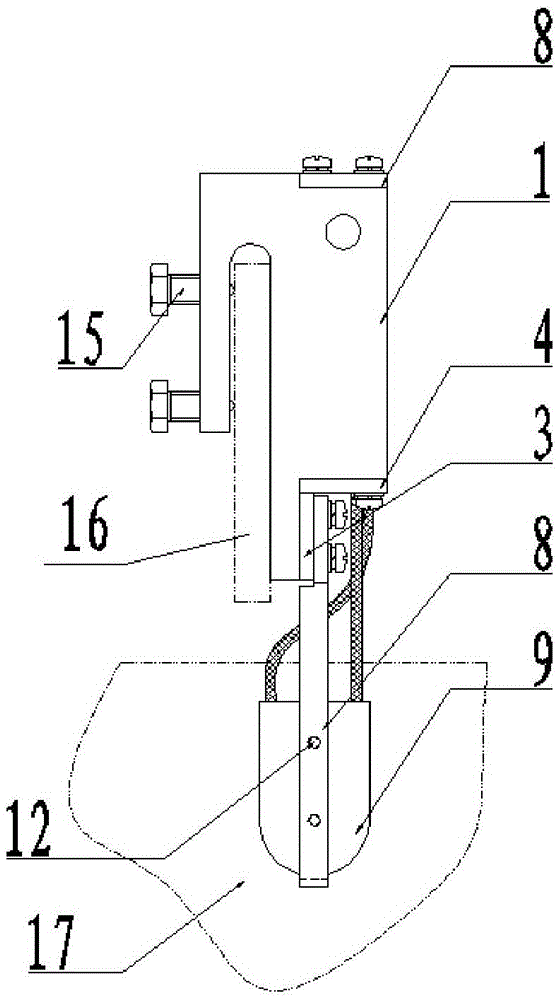

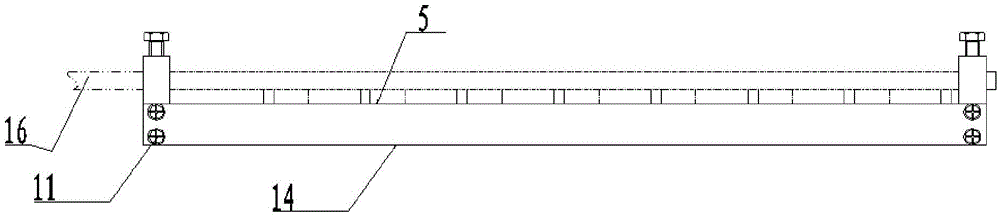

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] Such as Figures 1 to 6 As shown, the reactor fiber Bragg grating temperature measuring device is characterized in that it includes a left connection fixture 1 and a right connection fixture 2 installed on the reactor star frame 16, and the left connection fixture 1 and the right connection fixture 2 pass through the first tight The firmware 11 is connected with the lower cover 4 and the fixing plate 3, the rear side plate 5 is vertically inserted into the slots of the left connecting fixture 1 and the right connecting fixture 2, and the clamp plate 6 is horizontally inserted into the left connecting fixture 1 and the right connecting fixture 2. In the groove, the supporting sheet 7 is connected with the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com